DTF Transfers, or Direct-to-Film transfers, represent a cutting-edge printing technology that is transforming the garment decoration landscape. This technique allows designers to print high-quality designs onto a special film that is subsequently heat-applied to a variety of fabrics, offering versatility and durability. Unlike traditional methods such as screen printing or direct-to-garment (DTG), DTF printing stands out for its vibrant color reproduction and lower setup costs, making it an excellent choice for small businesses. With the ability to produce intricate and colorful designs, it serves as a perfect solution for those looking to enter the custom apparel market. In this guide, we will explore the numerous DTF printing advantages and how they can reshape your approach to textile printing.

When considering textile printing options, methods like Direct-to-Film (DTF), Screen Printing, and Heat Transfer Vinyl (HTV) each come with unique strengths. DTF, a process that involves applying prints from a film directly onto fabric, is becoming increasingly popular due to its ability for vibrant color depth and versatility across different materials. In contrast, traditional techniques such as screen printing thrive on simplicity and cost-effectiveness for bulk orders, while DTG is known for delivering high-resolution images, particularly for complex designs. As customization trends rise, many businesses are turning to modern solutions like DTF printing to fulfill their specific needs efficiently, bridging the gap between quality and affordability in garment decoration.

Understanding DTF Transfers: A Modern Printing Technique

DTF transfers, or Direct-to-Film transfers, represent a cutting-edge technology in the realm of textile printing. This process transfers high-quality images onto fabric with remarkable precision. Unlike traditional methods that may limit color variety or the complexity of designs, DTF expands the possibilities, allowing intricate designs to shine through vividly on a variety of fabric types, including cotton and polyester. As the demand for customization in apparel rises, DTF makes it feasible for businesses to create unique pieces that resonate with their clientele.

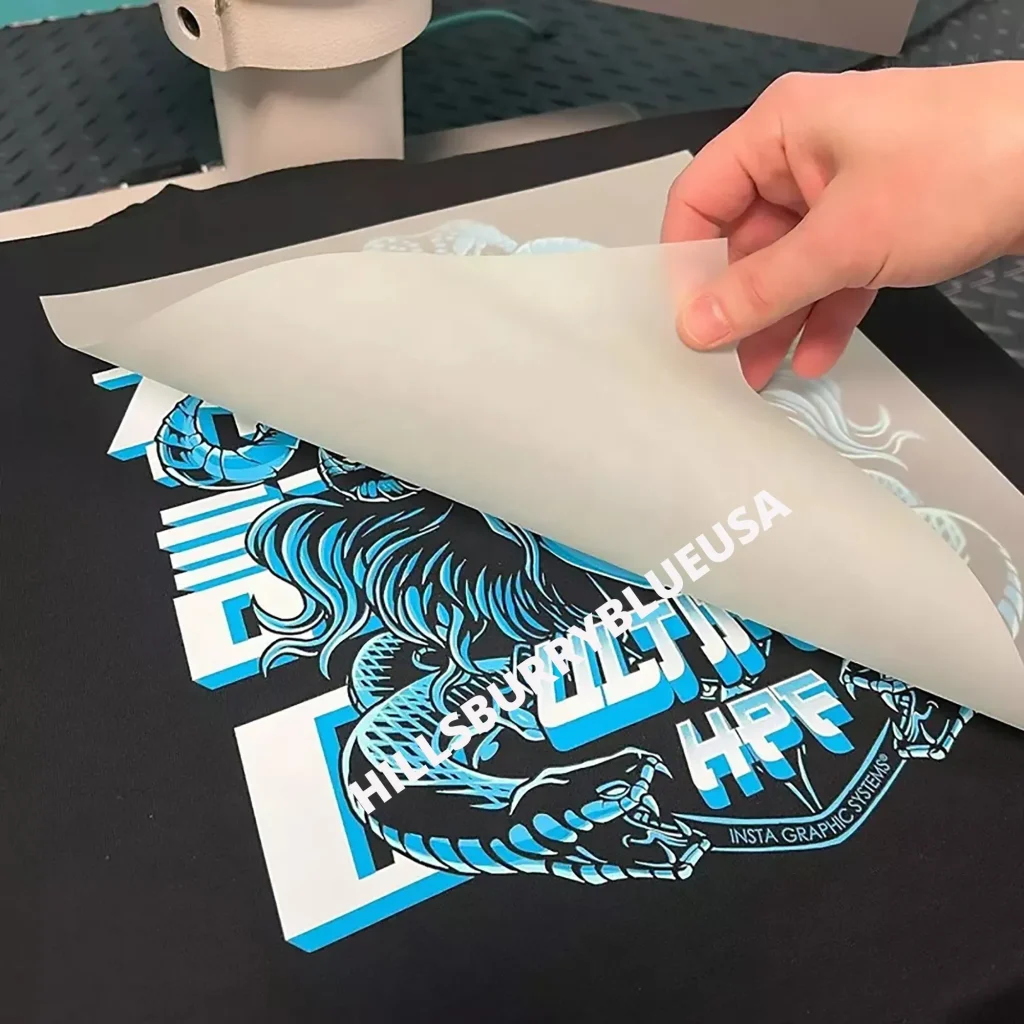

The DTF process involves printing an image onto a special film coated with an adhesive powder, which is then heated to transfer the design onto the clothing. This method stands out for its ability to produce soft prints that maintain the fabric’s breathability, ensuring comfort for the wearer. With vibrant colors that resist fading, DTF technology has become a popular choice among both small and large businesses looking to enhance their product offerings and elevate their branding strategies.

Comparing DTF Transfers with Screen Printing

When discussing garment printing options, screen printing is often the first method that comes to mind. While it excels in producing durable prints for large orders, it has considerable limitations regarding intricate designs. DTF transfers, on the other hand, provide a solution for businesses looking to create detailed, multicolor designs without incurring significant costs. Unlike screen printing, which requires multiple screens for different colors, DTF simplifies the process, making it quicker and more cost-effective for those willing to experiment with unique aesthetics.

Furthermore, while screen printing typically thrives on solid color designs, DTF is able to showcase photo-quality images and complex artworks. This versatility allows designers to spot numerous textures and color gradients, appealing to modern consumers who seek uniqueness in their clothing. Therefore, for businesses aiming to diversify their product line, DTF transfers are better suited for fulfilling various client requests without the financial burden associated with traditional printing methods.

The Benefits of DTF Printing Versus Direct-to-Garment (DTG)

Direct-to-Garment (DTG) printing is often praised for its high-quality output and ability to reproduce images with remarkable detail. However, it is generally less cost-effective for larger batches and has restrictions when it comes to non-cotton fabrics. In contrast, DTF printing overcomes these obstacles by providing the same level of detail at a lower cost per item, especially for bulk orders. This makes DTF a more practical option for businesses that need to manage budget constraints while still delivering beautiful printed garments to customers.

Additionally, DTG requires specialized equipment and careful maintenance, which can incur additional expenses. On the other hand, DTF transfers can be produced with more accessible tools, allowing small business owners and crafters to invest less up front. The resulting flexibility in operation not only encourages experimentation with different fabric types and colors but also positions DTF as a favorable choice for customized apparel and small batch production.

Durability and Longevity: DTF vs. Heat Transfer Vinyl (HTV)

Heat Transfer Vinyl (HTV) is often chosen for its ease of use, particularly for personal projects or small quantities. However, when compared to DTF transfers, HTV faces challenges in terms of durability and design complexity. While HTV prints can be vibrant, they tend to result in a heavier feel on the fabric, impacting comfort during wear. In contrast, DTF offers a lightweight solution that allows for a soft hand feel, which is especially important for apparel intended for daily use.

Moreover, DTF transfers boast higher resilience, especially after multiple washes, making them ideal for products that require long-lasting quality. Since DTF ink penetrates the fabric’s fibers, the designs maintain their look without cracking or peeling over time, surpassing the performance of HTV. For businesses striving for satisfaction and repeat customers, DTF printing emerges as an advantageous alternative, ensuring that the garments not only look great but also stand the test of time.

Recent Innovations in DTF Printing Technology

DTF printing technology is continuously evolving, with recent advancements significantly improving the quality and efficiency of the printing process. Innovations in ink formulations have translated into better adhesion properties and color intensity, allowing for sharper and more vibrant prints. As manufacturers adapt to market demands, the introduction of eco-friendly inks promises to appeal to environmentally-conscious consumers while maintaining the high standards expected from DTF outputs.

Moreover, the trend towards customization has skyrocketed, with DTF printing standing at the forefront of this movement. Businesses looking to meet consumer demands for bespoke and limited-edition pieces find that the DTF method supports quick turnaround times and high-quality production. These advancements not only enhance customer satisfaction but also position DTF transfers as the go-to method for modern garment printing solutions.

Selecting the Right Printing Method for Your Business Needs

When choosing a printing method, it is essential to assess your business goals and the types of products you wish to offer. DTF transfers provide a mix of quality, efficiency, and cost-effectiveness that can serve both newcomers to the garment industry and seasoned professionals. Their capacity for adaptation to various fabric types makes them ideal for businesses aiming to establish or expand their product offerings. It’s crucial to weigh the advantages of DTF against other methods, taking into account turnaround times, print complexity, and overhead costs.

Moreover, understanding your target audience’s preferences will guide your choice of printing technology. If your consumers prioritize unique, high-quality designs, DTF’s ability to deliver exceptional prints at a reasonable price makes it a smart investment. By leveraging the benefits of DTF, businesses can position themselves as leaders in the competitive apparel market while accommodating the growing demand for customized, quality products.

Frequently Asked Questions

What are DTF Transfers and how do they differ from screen printing?

DTF Transfers, or Direct-to-Film transfers, involve printing designs onto a special film that is later heat-transferred onto fabric. Unlike screen printing, which uses ink applied directly through screens, DTF transfers allow for intricate, vibrant designs with less setup cost, making them ideal for small runs.

What are the advantages of using DTF printing over heat transfer vinyl (HTV)?

DTF printing offers several advantages over heat transfer vinyl (HTV), including better color vibrancy and durability. DTF transfers can print on various fabric types, including those that HTV may struggle with, resulting in softer prints that do not feel heavy on the fabric.

How does DTF printing compare to Direct-to-Garment (DTG) printing?

DTF printing is generally more versatile than Direct-to-Garment (DTG) printing, as DTF can be used on a wider variety of materials. While DTG excels in high-detail, colorful prints, it can be slower for larger orders and is less effective on non-cotton fabrics.

Why should I consider DTF Transfers for my garment decoration business?

Considering DTF Transfers for your garment decoration business offers multiple benefits, including lower setup costs, vibrant print quality, and durability. DTF is especially suited for businesses looking for efficient and customizable printing solutions for various fabric types.

Are DTF Transfers eco-friendly compared to other printing methods?

Yes, many DTF Transfers now utilize eco-friendly ink formulations, aligning with the growing demand for sustainable printing in the textile industry. This makes DTF printing a more environmentally conscious choice compared to some traditional methods like screen printing.

What types of fabric can I use with DTF Transfers?

DTF Transfers are incredibly versatile and can be applied to a wide range of fabrics including cotton, polyester, and their blends. This adaptability makes DTF a suitable option for various applications, from fashion apparel to promotional products.

| Method | Advantages | Disadvantages |

|---|---|---|

| DTF (Direct-to-Film) | Versatile, vibrant colors, durable, low setup costs. | Requires specialized equipment. |

| Screen Printing | Cost-effective for large runs, durable prints for simple designs. | Not ideal for intricate designs, high setup costs. |

| DTG (Direct-to-Garment) | Highly detailed, vibrant colors for complex designs. | Slower for large orders, cost of ink may be higher. |

| HTV (Heat Transfer Vinyl) | User-friendly for small projects, simple to apply. | Limited colors, feels heavier on the fabric. |

Summary

DTF Transfers offer a compelling option in the realm of garment decoration, distinguishing themselves with unique advantages that cater to modern printing needs. In an industry where quality and customization are paramount, DTF technology emerges as a versatile and effective solution, allowing for vibrant and durable results on a variety of fabrics. As businesses and consumers alike seek personalized options, DTF Transfers continue to set a standard for excellence, ensuring that your design projects not only meet but exceed expectations.