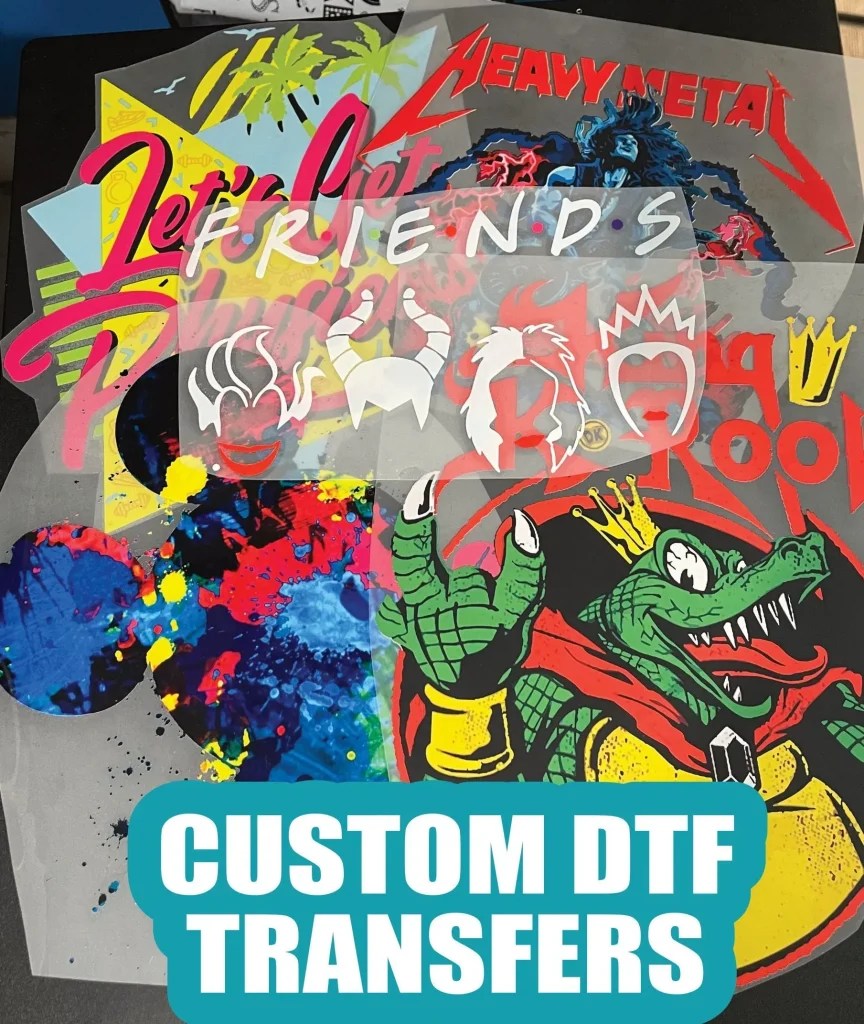

DTF transfers, or Direct-to-Film transfers, are revolutionizing the custom garment printing industry by combining quality with versatility. This innovative printing technology allows for vibrant, detailed images to be transferred onto various fabrics, making it an ideal choice for creating eye-catching apparel. The DTF printing process not only enhances the aesthetic appeal of garments but also ensures the longevity of the prints, with durable, fade-resistant results even after multiple washes. As we explore the advantages of DTF transfers, you will discover how this method simplifies the printing process and empowers both businesses and individuals to produce customized designs. Join us in unlocking the potential of DTF transfer technology in this comprehensive guide.

In recent years, Direct-to-Film technology has gained traction as a preferred method for achieving high-quality prints in fabric design. This exciting printing application facilitates the transfer of designs onto textiles with remarkable efficiency, allowing for stunning visuals on a variety of materials. Whether referred to as DTF transfers or direct-to-film printing, the process stands out for its ability to deliver detailed results that meet diverse aesthetic needs. With the numerous benefits associated with this contemporary printing approach, including ease of use and cost-effectiveness, it’s no wonder that more creators are seeking to leverage DTF for their artistic pursuits. Discover how this cutting-edge technique can elevate your printing projects and lead to stunning creations.

Understanding DTF Transfers: The Basics

DTF transfers, short for Direct-to-Film transfers, are a relatively new way of transferring graphics onto fabrics and other surfaces. This innovative method involves printing a design onto a specially coated film, which can then be heat-pressed onto the material of choice. Unlike traditional printing methods, DTF allows for intricate designs to be printed with high levels of detail and vibrant colors. The resulting prints are noted for their durability and resistance to wear, making them ideal for fashion and promotional products alike.

The process of DTF transfer begins by preparing the artwork, which is printed on the film using specialized DTF printers. Following this, a powder adhesive is applied, and the film is heated to bond the design to the transfer. After cooling, the film is ready to be heat-pressed onto a garment. This adaptability to various fabrics such as cotton, polyester, and blends ensures that businesses can cater to diverse client needs, enhancing the appeal of DTF transfers in the garment printing market.

Advantages of DTF Transfers in Custom Printing

One of the significant advantages of DTF transfers is their ability to produce high-quality output that consumers have come to expect. The prints boast vibrant colors and fine detail, making them perfect for complex designs that need to catch the eye. Moreover, DTF transfers are resistant to fading and cracking, ensuring that the designs remain intact long after the initial application, even after multiple washes. This durability offers an excellent return on investment for businesses as it minimizes the need for reprints.

Another key advantage of DTF transfers is their versatility. This method can be utilized on a range of materials, allowing for creative applications not just limited to garments but also including accessories like bags and hats. Additionally, DTF printing is cost-effective due to its minimal waste and ability to print designs on demand. This flexibility is particularly beneficial for small businesses and custom orders, as it eliminates the need for stockpiling pre-printed materials.

Recent Innovations Driving DTF Printing

The DTF printing market has seen exciting innovations that significantly improve the process. For instance, advancements in large-format DTF printers have enabled companies to cater to increased consumer demand by offering faster turnaround times. This is demonstrated by businesses like Eazydtf, which has enhanced its operations by providing same-day shipping for customers, marking a significant milestone in the service efficiency of DTF transfers.

Moreover, the development of specialized services targeted at the commercial print trade, such as that offered by Snuggle, showcases the scalability of DTF printing. By producing thousands of A4-format transfers daily, this innovation not only supports larger businesses but also solidifies the foundation for smaller shops to thrive in a competitive market, encouraging the growth of DTF as a popular choice for custom garment printing.

How to Effectively Use DTF Transfers

To get started with DTF transfers, it is essential to understand the necessary equipment and setup. Investing in high-quality DTF printers and inks is crucial as these elements directly impact the print quality and durability of the transfers. Additionally, setting up a dedicated workspace that accommodates printing and heat application processes is important for efficiency.

Learning the DTF printing process involves not just understanding the technicalities of the machinery but also exploring design options. Utilizing online tutorials, workshops, and community resources can provide invaluable insights on best practices in DTF printing. As one gains familiarity with the process, experimenting with unique designs and marketing skills will be critical in standing out in the crowded custom printing space.

Addressing Consumer Concerns about DTF Transfers

Despite the benefits of DTF transfers, consumers naturally have concerns regarding their longevity and removability. Understanding how well DTF prints hold up over time is vital for both consumers and businesses. Recent studies have investigated these performance characteristics, providing insights that can help set realistic expectations, thereby addressing concerns regarding the quality and durability of these transfers.

It’s also important for businesses to convey the proper care instructions to customers to ensure the longevity of the prints. Proper washing and handling techniques can significantly affect the lifespan of DTF designs. Educating consumers about the requirements for maintaining their garments with DTF artwork will foster trust and satisfaction, promoting ongoing dialogue about the technology.

The Future of DTF Transfers in Textile Printing

Looking ahead, DTF transfers are positioned to become even more popular as advancements continue. The combination of technology enhancements and growing consumer awareness will likely lead to widespread acceptance of DTF printing in various sectors. Companies are increasingly focusing on education and community engagement to equip new users with the knowledge they need to maximize the benefits of DTF transfer technology.

Additionally, as sustainability becomes a key consideration in textile production, DTF printing offers eco-friendly advantages by reducing material waste and energy consumption. This trend aligns with consumer preferences for sustainable products, thus presenting DTF transfers as a forward-thinking choice in the custom printing industry. With ongoing innovations and market adaptation, the future indeed looks bright for DTF transfers in shaping the landscape of textile printing.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a modern printing method used to transfer designs onto fabrics and other surfaces. The process involves printing a design onto a special film, which is then applied to the material using heat and pressure. This technique produces vibrant colors and sharp details, making it ideal for various applications, especially in custom garment printing.

What are the advantages of DTF transfers compared to traditional printing methods?

DTF transfers offer several advantages over traditional printing methods, including exceptional print quality—resulting in durable and vibrant designs that resist fading. Additionally, DTF printing is versatile, compatible with a wide range of materials, and easier to implement, requiring less specialized training. This can lead to cost savings for businesses, as they can print on-demand, reducing waste and inventory costs.

How can I get started with DTF transfers?

To get started with DTF transfers, first, invest in reliable DTF printing equipment, including a high-quality printer and heat press. Create a dedicated workspace for your setup. Next, educate yourself about the DTF printing process through online resources and tutorials. Once you’ve mastered the basics, experiment with various designs to refine your skills before promoting your DTF transfer services to potential clients.

What materials can DTF transfers be applied to?

DTF transfers are highly versatile and can be applied to various materials, including cotton, polyester, and blends. This adaptability makes DTF technology suitable for printing on a wide range of products like t-shirts, hoodies, bags, and even some home textiles, allowing for diverse customization options.

Are DTF transfers durable and long-lasting?

Yes, DTF transfers are known for their durability and long-lasting quality. The prints maintain their vibrancy and integrity even after multiple washes, exhibiting resistance to cracking or fading. Recent studies also suggest that DTF prints perform well regarding removability without compromising the fabric, making them an excellent choice for long-term use.

What innovations are currently shaping the future of DTF transfers?

Recent innovations in DTF transfers include advancements in printing technology, such as the introduction of large-format DTF printers, which enhance printing efficiency and quality. Companies like Eazydtf are facilitating fast order fulfillment with same-day shipping, while others are launching specialized trade services to meet the growing demand for DTF printing. Ongoing educational initiatives, such as webinars, also aim to keep users informed about the latest developments in DTF transfer technology.

| Key Aspects of DTF Transfers | ||

|---|---|---|

| Definition | Direct-to-Film (DTF) transfers involve printing designs on a thin film, then applying them to surfaces using heat and pressure. | |

| Advantages | 1. Quality Output: Produces durable, detailed prints resistant to fading and cracking. 2. Versatility: Applicable to various materials (cotton, polyester, blends). 3. Ease of Use: Minimal training required for operation. 4. Cost-Effective: Reduces waste and inventory costs by printing on-demand. | |

| Innovations | Recent advancements include investments in large-format DTF printers by companies like Eazydtf, and the launch of new trade services by Snuggle, enhancing customer satisfaction and scalability. | |

| Educational Resources | Initiatives like the ‘Discovering DTF’ webinar hosted by GJS aim to deepen understanding and engage the community in DTF technology. | |

| Consumer Concerns | Concerns about the longevity and removability of DTF transfers are being studied, guiding consumer and business expectations for the technology’s performance. | |

| Getting Started | 1. Research suitable DTF printers and inks. 2. Set up a dedicated workspace. 3. Learn the printing process through tutorials and forums. 4. Experiment with design and techniques. 5. Market your services and build a portfolio. | |

| Future Outlook | With growing recognition of DTF advantages and continuous improvements, its popularity in the garment printing industry is expected to rise, driven by companies like Eazydtf and Snuggle. | |

Summary

DTF transfers represent a significant advancement in the world of custom garment printing, providing high-quality and versatile printing solutions. This innovative method allows designers and businesses alike to create vibrant, durable prints on various fabrics with ease. As technology and educational resources expand, the adoption of DTF transfers is set to increase, making it a key player in the future of textile printing. This comprehensive approach not only enhances product offerings but also fosters creativity and efficiency in the printing process, ensuring that DTF transfers will continue to revolutionize the industry.