In the ever-evolving landscape of custom apparel printing, DTF transfers stand out as a revolutionary technology that enhances the capabilities of Direct-to-Film printing. This innovative technique allows for vibrant, high-quality designs to be printed effortlessly on a variety of fabrics, making it a favorite choice for apparel customization. As businesses and creators seek to stand out in a competitive market, understanding the DTF transfer process becomes essential. The blend of versatility and impeccable detail offered by DTF printing technology enables users to cater to diverse design needs. This guide will delve into everything you need to know about DTF transfers, empowering you to harness their full potential.

When it comes to fabric decoration, the world of Direct-to-Film transfers has introduced a fresh perspective on apparel design. Often referred to as heat transfers or film printing, this method is rapidly gaining popularity among small businesses and larger manufacturers alike. Its ability to produce intricate graphics and vivid colors makes it a strong contender against traditional printing techniques. Users of this technology experience a seamless approach to customizing clothing, unlocking new creative avenues. Join us as we explore the details of this remarkable printing technique and its implications for the future of custom apparel.

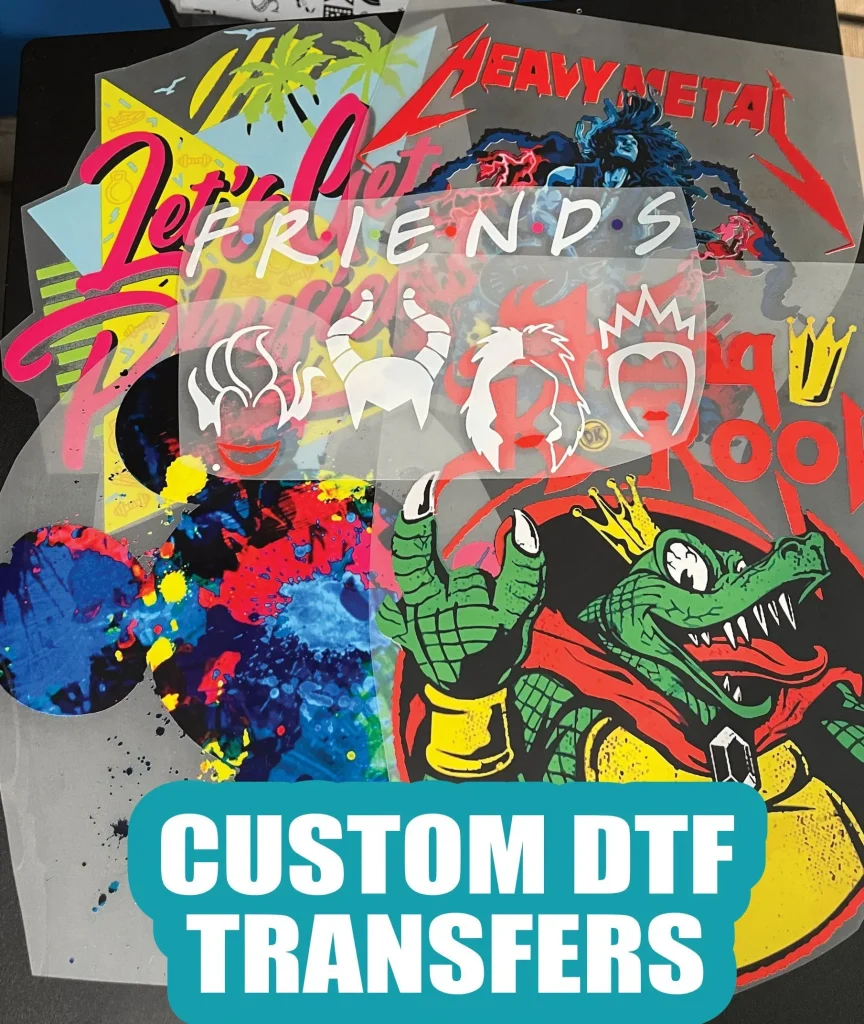

Understanding DTF Transfers in Custom Apparel

DTF transfers are transforming the landscape of custom apparel printing by providing an effective and innovative method for transferring designs onto fabrics. Essentially, this technique involves printing high-quality designs onto a specially coated film, which is then transferred onto a variety of garment materials through a heat application process. The resulting prints boast vivid colors and intricate details, making them a popular choice for brands looking to create unique apparel designs. This non-invasive printing method not only allows for vibrant imagery but also remains cost-effective, particularly for small-sized orders.

One major advantage of DTF transfers is their ability to adapt to various fabric types. Unlike some traditional printing methods that may not yield satisfactory results on certain materials, DTF printing technology provides flexibility, making it suitable for cotton, polyester, and even blended fabrics. This compositional versatility allows businesses to broaden their product offerings, catering to customer preferences in apparel customization markets. Furthermore, with the ease of use associated with DTF transfers, even newcomers to the world of printing can achieve professional-grade results.

The DTF Transfer Process Explained

Understanding the DTF transfer process is crucial for anyone looking to utilize this innovative approach to custom apparel printing. The process begins with the creation of a design using graphic design software, which is then printed onto a specially designed PET film using a DTF printer and compatible inks. Following the initial print step, an adhesive powder is applied to the fresh ink, ensuring that the design will properly adhere to the fabric during the transfer process. This meticulous sequence of actions allows for high-resolution prints that capture even the finest details.

After applying the adhesive, the film is cured in a heat press, which solidifies the powder and readies it for transfer. The critical moment comes when the film is positioned on the intended fabric, and heat and pressure are applied. This transferring step is key to achieving high-quality results, as it requires a precise combination of timing and temperature. Once the heat application is complete, the film is peeled away, revealing a stunning, bright design that is resistant to fading and washing. This well-structured process showcases the technical sophistication of DTF printing while ensuring that users can produce visually impactful apparel.

Advantages of DTF Transfers Over Traditional Printing

One of the standout advantages of DTF transfers is their cost-effectiveness, especially for small businesses or niche markets. Unlike traditional screen printing techniques that typically require large volume orders, DTF printing eliminates minimum order quantities, enabling businesses to experiment with personalized designs without significant financial risk. This flexibility encourages creativity and innovation among custom apparel makers, allowing them to cater to unique customer requests without the burden of bulk orders.

Additionally, DTF transfers excel in providing a diverse range of fabric compatibility, making them a versatile option for various clothing items. The ability to print on materials like cotton, polyester, and blends means that brands can easily diversify their product lines, appealing to different demographics and markets. Furthermore, the vibrant colors and fine details achieved with DTF technology draw consumer attention and enhance the overall attractiveness of the apparel, thus promoting sales and increasing brand loyalty.

Recent Innovations in DTF Transfer Technology

The DTF transfer market has seen rapid advancements recently, with companies consistently unveiling innovations aimed at improving print quality and user experience. For instance, Sam’s DTF Transfers recently launched a premium service that offers high-quality in-house DTF transfer capabilities without minimum order requirements. This service has particularly resonated with small businesses seeking to expand their customization offerings without overspending on inventory. Innovations like this demonstrate the growing demand for accessible and customizable printing solutions in the apparel industry.

Another significant development in the DTF sector is the introduction of Insta Graphic Systems’ latest product, the Insta DTF heat transfer. This newly developed technology boasts enhanced print durability and quality, further solidifying DTF transfers’ position as a viable replacement for conventional printing methods. Innovations such as these indicate a response to market needs for better quality and reliability in apparel production, signaling that DTF printing technology continues to evolve and is gaining traction among established and emerging garment production companies.

Common Concerns and Challenges with DTF Transfers

While DTF transfers offer numerous benefits, there are certain challenges and concerns associated with this printing method. One primary drawback is the initial investment required for high-quality DTF printers, heat presses, and specialized inks. For small businesses and startups, this upfront cost can be a significant barrier to entry. Additionally, the learning curve associated with mastering the DTF transfer process may deter some potential users who are accustomed to simpler printing techniques.

Moreover, durability is a common concern among users of DTF transfers. If the application process is not executed properly—whether due to incorrect temperature settings or improper handling—the resulting design may crack or peel over time. This can affect customer satisfaction and lead to negative reviews for businesses. Thus, it is essential for users to fully understand the DTF transfer process and invest time in practice to ensure longevity and quality in their custom apparel offerings.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

The DTF transfer process utilizes Direct-to-Film printing technology to create designs on a special PET film. First, a design is created using graphic software, printed on the film with DTF inks, and then an adhesive powder is applied. The film is cured with heat, and transferring the design to fabric is completed using a heat press, resulting in vibrant and detailed custom apparel.

What are the advantages of using DTF Transfers for custom apparel printing?

DTF Transfers offer several advantages, including cost-effectiveness due to no minimum order requirements, versatility across various fabrics, high-resolution prints with bright colors, and ease of use for beginners. This makes them an ideal choice for businesses and individuals looking for effective apparel customization.

What materials can be used with DTF printing technology?

DTF printing technology can be applied to a diverse range of fabrics, including cotton, polyester, and fabric blends. This versatility allows for creative custom apparel options suitable for different styles and market demands.

Are there any disadvantages to using DTF transfers?

While DTF transfers have many benefits, they come with drawbacks such as the initial investment cost for DTF printers and heat presses, a learning curve associated with mastering the printing process, and potential durability issues if the transfer is not applied correctly.

How does DTF transfer compare to traditional screen printing methods?

DTF transfers provide distinct advantages over traditional screen printing, including the ability to produce intricate designs with more vibrant colors and gradations. Additionally, DTF printing allows for smaller batch orders without minimums, making it more accessible for startups and small businesses.

What recent innovations have impacted the DTF transfer landscape?

Recent innovations in DTF transfer technology, such as the launch of premium services by companies like Sam’s DTF Transfers and advanced products like Insta DTF heat transfers from Insta Graphic Systems, have enhanced print quality and usability. These developments contribute to the ongoing evolution of custom apparel printing solutions.

| Key Feature | Description |

|---|---|

| What are DTF Transfers? | A printing method where designs are printed on a special film and applied to fabric using heat and pressure. |

| How DTF Transfers Work | 1. Design Creation, 2. Printing on PET film, 3. Powder application, 4. Heating, 5. Transfer to fabric, 6. Peeling the film. |

| Advantages of DTF Transfers | Cost-effective, versatile for various fabrics, vibrant colors, easy to use. |

| Disadvantages of DTF Transfers | High equipment costs, learning curve, potential durability issues if not applied correctly. |

Summary

DTF transfers are revolutionizing the world of custom apparel printing, providing a dynamic solution for producing intricate and vibrant designs on various fabrics. This innovative printing technique stands out due to its capability to achieve high-resolution results without the need for minimum orders, making it particularly attractive for small businesses and large-scale manufacturers alike. As advancements continue and new products are launched within the DTF transfer market, the implications for customization and production processes are significant, fostering a new era of creativity and efficiency in the apparel industry. By leveraging these innovative solutions, brands can meet the rising consumer demand for personalized clothing while ensuring quality and uniqueness.