In the rapidly advancing realm of fashion, DTF transfers, also known as Direct-to-Film printing, are emerging as a game-changing innovation. This modern printing technique enables designers to create custom apparel with ease, achieving vibrant colors and intricate patterns that capture consumer attention. As brands aim to keep up with the demand for unique and personalized styles, DTF transfers provide an efficient and high-quality solution. Additionally, the sustainable fashion printing aspect of DTF technology reduces waste and utilizes eco-friendly materials, aligning with the growing consumer desire for environmentally responsible options. With digital printing technology at its core, DTF transfers are indeed revolutionizing how we think about custom clothing in today’s market.

Direct-to-Film printing, often abbreviated as DTF, marks a significant leap in modern fashion customization techniques. This innovative process allows designers to apply elaborate designs onto garments seamlessly, ensuring that each piece resonates with personal flair. As businesses leverage this digital printing technology, they are discovering the balance between creativity and sustainability in their manufacturing practices. The recent shift towards sustainable fashion printing not only meets consumer demand for distinct clothing but also champions eco-conscious production methods. By embracing this cutting-edge approach, fashion brands are transforming traditional practices, paving the way for a more personalized and sustainable future in the industry.

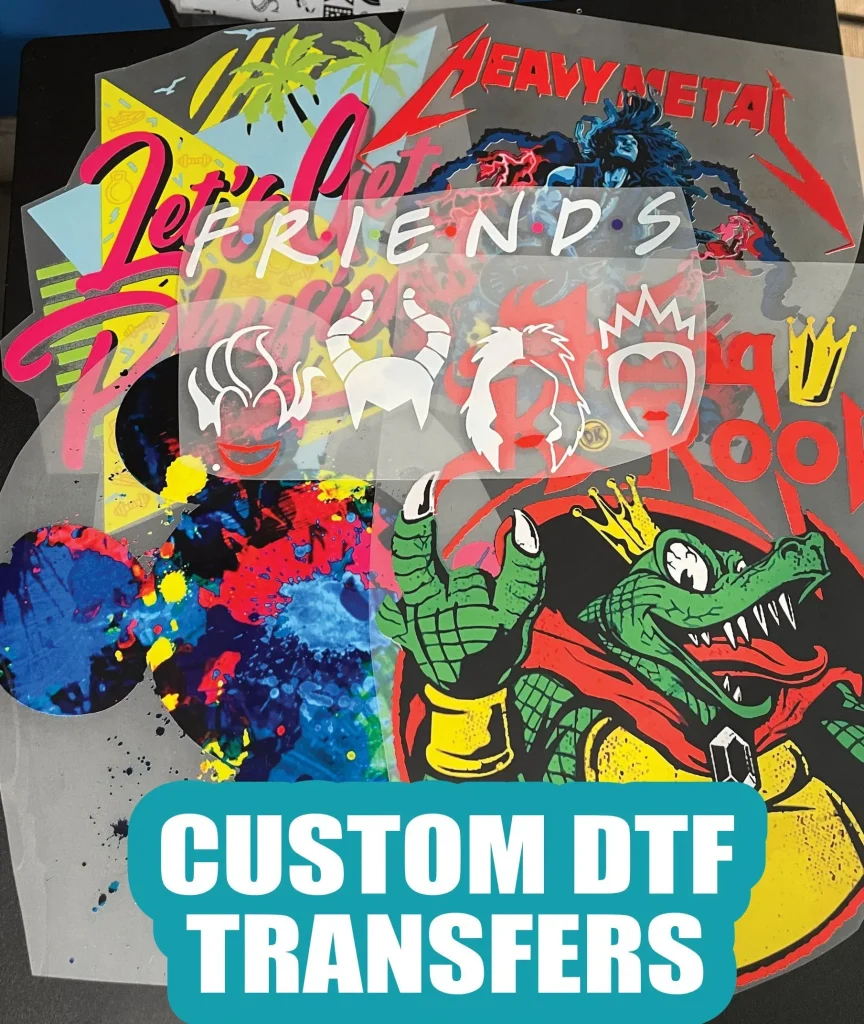

The Benefits of DTF Transfers in Custom Apparel

DTF transfers offer a multitude of benefits when it comes to custom apparel. One of the standout advantages is the exceptional quality that can be achieved. The vibrant colors and fine details produced through Direct-to-Film printing allow for designs that truly pop on fabric. This feature is particularly appealing to custom apparel businesses, which rely on eye-catching visuals to attract customers and set themselves apart in a competitive market. Additionally, DTF technology enables compatibility with a wide range of materials, so unique fabrics that were previously challenging to print on can now be easily utilized.

Moreover, DTF transfers provide a level of customization that is highly sought after in today’s fashion landscape. As consumers continue to gravitate towards personalized items that reflect their individuality, DTF printing allows artists and designers to produce limited runs of unique pieces. This elevates the concept of custom apparel from mere garments to collectible art pieces, catering to a growing consumer base that values exclusivity.

Sustainable Fashion Printing: Embracing DTF Transfers

As the fashion industry increasingly prioritizes sustainability, DTF transfers stand out as a highly eco-friendly option. Traditional printing methods often involve harmful chemicals and generate significant waste, which contradicts the move towards greener practices in apparel manufacturing. In contrast, DTF technology typically uses water-based inks, which are less detrimental to both the environment and the workers involved in the manufacturing process. By adopting DTF transfers for their production, brands can help mitigate their environmental impact while still delivering high-quality fashion.

Furthermore, the efficiency of DTF printing contributes to sustainability goals by reducing excess waste. The precision of this technology minimizes errors that are common in other printing methods, ensuring that only necessary materials are utilized. This aligns perfectly with the principles of sustainable fashion, appealing to environmentally-conscious consumers who are looking for stylish yet sustainable options.

Technological Advancements in DTF Printing

The advancements in Direct-to-Film printing technology have been remarkable, allowing for improved efficiency and output quality in the fashion printing sector. Recent innovations include the introduction of faster processing speeds and enhanced ink formulations that provide better color resilience and vibrancy. This is particularly significant for fashion brands that operate in a fast-paced environment and require quick turnarounds in order to keep up with ever-evolving trends and consumer demands.

Moreover, as technology evolves, the cost barriers associated with entering the DTF market have begun to diminish. Innovations in printer designs make it more accessible for small and medium businesses looking to incorporate custom printing into their offerings. This democratization of technology can potentially lead to an influx of new players in the market, further fostering creativity and innovation in fashion design.

Fashion Customization Techniques Using DTF Transfers

Fashion customization techniques have taken on new dimensions with the advent of DTF transfers. Designers can now create intricate patterns and personalized graphics that would have been much more difficult to achieve with older methods such as screen printing or embroidery. The flexibility of DTF printing means that even small runs of unique designs are feasible, allowing brands to offer personalized items at scale, catering to the desire for individuality among modern consumers.

Additionally, DTF printing opens the door to creative experimentation. Designers can combine various elements—such as photographs, textures, and typography—onto a single piece of clothing, pushing the boundaries of traditional fashion design. This new form of customization not only appeals to consumers looking for something different but also empowers artists and designers to unleash their creativity in ways that resonate with today’s fashion landscape.

Challenges Facing the Adoption of DTF Transfers

Despite the numerous benefits of DTF transfers, there are still several challenges that brands face when considering this printing method. One significant hurdle is the initial investment in specialized equipment required to execute DTF printing effectively. For smaller businesses or startups, this can be a substantial barrier to entry, preventing many from taking advantage of the advancements that DTF technology has to offer.

Moreover, there are concerns regarding the durability and longevity of DTF prints compared to other established methods such as screen printing or direct-to-garment (DTG) printing. Prospective users may worry that the prints may not withstand the rigors of wear and washing as well, which could affect customer satisfaction and brand reputation. Addressing these quality concerns is crucial for the long-term adoption of DTF printing in the competitive fashion industry.

The Future of Fashion Printing with DTF Technology

The future of fashion printing is undoubtedly intertwined with the advancements in DTF technology. As the market continues to grow, driven by consumer demand for customizable and sustainable options, we can expect to see more brands implementing DTF solutions. This shift signifies a pivotal moment for the fashion industry, where traditional printing practices may be replaced by more innovative and efficient methods that align with the evolving values of consumers.

Furthermore, as DTF technology continues to improve, the ability to create complex designs that meet the expectations of style-savvy consumers will enhance. The intersection of art and technology will redefine how fashion is produced, leading to a landscape where innovative prints can be created quickly and sustainably. In this new realm of fashion printing, DTF transfers will play an integral role, fostering collaboration between technology and creativity for future generations of designers.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel?

DTF Transfers, or Direct-to-Film transfers, are a cutting-edge printing method that involves printing designs onto a special film. The design is then transferred onto fabrics using heat and pressure. This process allows for vibrant colors and intricate designs, making it popular for custom apparel production.

Why are DTF Transfers preferred for sustainable fashion printing?

DTF Transfers are a sustainable fashion printing option due to their use of water-based inks and reduced waste in production. Unlike traditional printing methods, DTF minimizes environmental impact while maintaining high-quality prints, which appeals to eco-conscious brands and consumers.

How does DTF Transfers compare with other fashion customization techniques?

DTF Transfers stand out among fashion customization techniques due to their versatility and ability to produce detailed designs rapidly. Unlike screen printing or direct-to-garment (DTG) methods, DTF can efficiently handle smaller custom orders without sacrificing quality.

What are the advantages of using digital printing technology like DTF Transfers in fashion?

The advantages of using digital printing technology like DTF Transfers include high-quality outputs, quick turnaround times, and cost-effectiveness for small batches. This technology allows for more intricate designs while catering to the demand for personalized fashion among consumers.

What challenges are facing the adoption of DTF Transfers in the fashion industry?

Challenges facing the adoption of DTF Transfers include the initial equipment investment and concerns about print durability compared to traditional methods. Ensuring that DTF prints maintain their vibrancy after washing is crucial for brand loyalty and customer satisfaction.

Can DTF Transfers revolutionize the way designers create custom apparel?

Yes, DTF Transfers have the potential to revolutionize the creation of custom apparel by enabling designers to produce high-quality, customized pieces quickly and efficiently. As the technology advances, it will likely become an essential tool for both established and emerging fashion designers.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs on a film and transferring them to garments using heat, allowing vibrant colors on various fabrics. |

| Reasons for Popularity | 1. Customization Demand 2. High-Quality Output 3. Cost-Effectiveness 4. Quick Turnaround Times |

| Market Growth | DTF market projected to reach $1.5 billion by 2027, driven by demand for personalized apparel. |

| Technological Advancements | Improvements in printer technology and inks enhance quality and efficiency, facilitating mass production. |

| Sustainability | DTF uses water-based inks and minimizes waste, aligning well with eco-friendly production. |

| Challenges to Adoption | High initial equipment costs and concerns over durability compared to traditional methods are barriers to entry. |

Summary

DTF Transfers are dramatically reshaping the fashion landscape by offering an innovative approach to garment printing that combines efficiency, customization, and sustainability. This technology, utilizing a method where designs are transferred from a film onto fabrics, caters to the increasing consumer demand for personalized fashion while delivering high-quality outputs. As the industry embraces advancements in DTF technology, it faces both exciting opportunities and challenges, particularly regarding initial investments and print durability. Overall, the rise of DTF Transfers not only marks a significant technological advancement in fashion printing but also paves the way for a more environmentally conscious industry.