DTF Transfers, or Direct to Film transfers, are revolutionizing the apparel industry with their cutting-edge technology that drastically enhances custom apparel printing. These innovative DTF printing methods allow for vibrant, high-quality designs to be applied to a variety of fabrics with unmatched efficiency. As manufacturers and designers leverage DTF transfer efficiency, the possibilities for creativity in garment design have expanded significantly. This remarkable advancement not only reduces production time but also caters to a growing consumer demand for personalized, unique clothing items. In this article, we will delve into the transformative impact of DTF transfers on the apparel industry, highlighting key innovations and their role in shaping the future of custom printing.

The realm of custom garment printing is witnessing a transformative shift ushered in by the advances in Direct to Film transfer technology. Often referred to as DTF printing, this innovative approach utilizes special films to transfer intricate designs onto fabrics swiftly and effectively, catering to both small businesses and large manufacturers alike. With the growing popularity and technological advancements behind this process, custom apparel printing has never been more accessible and efficient. Innovations in DTF technology, such as gang sheets and streamlined platforms, are making it easier for businesses to adapt and thrive in a fast-paced market. As these developments gain traction, the apparel industry is embracing a future where custom designs can be realized more affordably and in less time, setting a new standard for what is possible in garment printing.

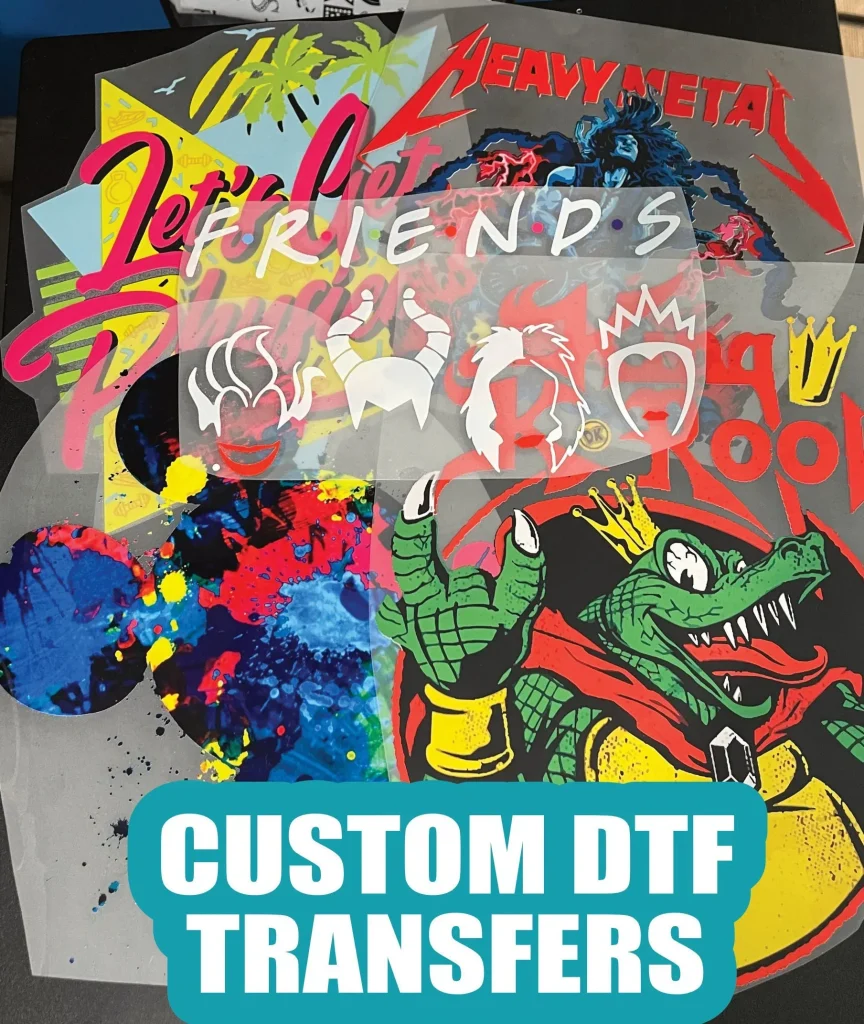

What Makes DTF Transfers Exceptional?

DTF (Direct-to-Film) transfers stand out for their unique ability to capture intricate details and vibrant colors that often elude traditional printing techniques. Using specialized films, this innovative printing process applies designs directly to apparel using heat and pressure, creating a robust and flexible bond. This not only allows for a plethora of design possibilities but also ensures that the prints remain durable and resistant to wear over time. Unlike screen printing, which can be labor-intensive and less adaptable to multiple color palettes, DTF printing technology efficiently streamlines the customization process, promoting creativity while maintaining high quality.

Moreover, the customization flexibility of DTF transfers is complemented by their environmentally friendly nature. The ability to produce high-quality garments on demand eliminates the need for excessive inventory and reduces fabric waste. As apparel industry innovations continue to unfold, DTF technology positions itself as not just a passing trend but a crucial component of a sustainable future for apparel manufacturing. Companies can now meet client demands with promptness and precision, making DTF an appealing choice across varying segments of the market.

The Process Behind DTF Transfers

Understanding the mechanics of DTF transfers is paramount for businesses venturing into this new printing frontier. The process begins with a digital design, which is printed onto a specialized film using high-resolution printers. This film is then coated with a powder adhesive that bonds the ink to the fabric during the heat transfer. The result is a seamless application that provides remarkable detail and color depth, bringing designs to life like never before. This level of craftsmanship sets DTF apart from traditional methods, making it a favored option for custom apparel printing.

In addition, the versatility of DTF transfers enables the printing of various materials, including cotton, polyester, and blended fabrics. This adaptability enhances the efficiency of production runs and allows businesses to cater to a wider demographic. The precision of the DTF printing process means that even the most complex designs can be replicated with fidelity, thus ensuring customer satisfaction and repeat business. As businesses embrace this revolutionary process, they open the door to new creative possibilities, embellishing their offerings with designs that resonate with customers.

The Efficiency of DTF Printing Technology

One of the most compelling attributes of DTF printing technology is its efficiency in production. Compared to traditional screen printing, which can be time-consuming and requires extensive setups for every color, DTF transfers streamline the workflow dramatically. With advancements in DTF equipment, businesses can produce high-quality prints in a fraction of the time, allowing for faster turnaround on customer orders. This efficiency not only aids in managing larger orders but also supports small businesses looking to keep pace with industry demands.

Moreover, innovations in DTF technology, such as gang sheets, further enhance productivity. By allowing multiple designs to be printed simultaneously on a single transfer sheet, gang sheets optimize material usage and minimize printing costs. This method makes DTF printing not only a creative avenue but also a financially viable option for brands aiming to stay competitive in a very dynamic apparel market. Such operational efficiencies position DTF as a cornerstone for the future of custom apparel printing.

Innovations Driving DTF Adoption

The apparel industry is witnessing a surge in DTF technology adoption, due in part to pioneering innovations by companies such as EazyDTF and Snuggle. EazyDTF’s substantial investment in advanced printers exemplifies the commitment to enhancing capacity and efficiency in custom apparel printing. As they expand their operational capabilities, they offer businesses same-day shipping options, which is a transformative leap in meeting consumer demands. Faster processing times allow retailers to fulfill orders more efficiently, thus promoting customer loyalty.

Similarly, Snuggle DTF’s introduction of a simplified web-to-print platform exhibits a notable shift in user accessibility. This user-friendly approach demystifies the DTF process for newcomers, encouraging smaller operators to embrace this advanced technology. The combination of high-quality output and reduced barriers to entry is reshaping the landscape, allowing a broader range of businesses to harness the benefits of DTF printing. As these companies lead the way, they not only promote their products but also advocate for DTF technology’s advantages across the industry.

The Future of Custom Apparel with DTF Technology

Looking ahead, the future of custom apparel appears bright with DTF technology at the forefront of innovation. As consumer expectations evolve towards greater personalization and immediacy, businesses are increasingly finding that DTF transfers not only meet but exceed these demands. Enhanced production capabilities, coupled with the ability to quickly adapt to design trends, position DTF as a critical player in the next generation of apparel manufacturing.

Furthermore, as brands prioritize sustainability and efficiency in their operations, DTF technology supports these goals through reduced waste and quicker turnaround times. With the apparel industry continuing to explore innovative ways to satisfy consumer cravings for unique and personalized products, DTF transfers will undeniably remain a key driving force in shaping the future of custom apparel. Companies that strategically adopt DTF printing will likely lead the charge toward a more agile and creative industry landscape.

Maximizing ROI with DTF Transfers

Investing in DTF transfers can yield significant returns on investment for businesses within the apparel industry. The technology’s cost-effectiveness stems from its ability to produce low-cost, high-quality prints that directly appeal to customers. Companies implementing DTF printing can optimize their production processes with faster turnaround times and reduced material waste, ultimately enhancing profit margins.

Additionally, with lower operation costs associated with DTF technology, businesses can respond flexibly to fluctuating market demands, introducing new designs and limited editions without heavy upfront costs. This agility translates directly into the capacity to innovate and scale, paving the way for more dynamic marketing strategies. As a result, those who embrace DTF transfers are better positioned to leverage their investments, tap into emerging market opportunities, and cultivate a loyal customer base.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel printing?

DTF Transfers, or Direct-to-Film transfers, involve printing designs onto a specially coated film that is then applied to fabric using heat and pressure. This innovative process enhances custom apparel printing by allowing for vibrant colors, intricate details, and high-quality designs, making it a popular choice in the apparel industry.

How has DTF printing technology impacted the efficiency of custom apparel production?

DTF printing technology has significantly boosted production efficiency in custom apparel. By using DTF Transfers, businesses can streamline the printing process, reduce material waste with techniques like gang sheets, and achieve quicker turnaround times, enabling them to meet customer demands swiftly.

What innovations are driving the growth of DTF Transfers in the apparel industry?

Recent innovations such as EazyDTF’s expansion of capacity and Snuggle DTF’s web-to-print platform are driving growth in DTF Transfers. These developments improve accessibility for businesses entering the custom apparel market and enhance production capabilities, solidifying DTF technology’s place in apparel industry innovations.

Can DTF Transfers be used for a variety of fabric types?

Yes, DTF Transfers are versatile and can be applied to a wide range of fabric types, including cotton, polyester, and blends. This adaptability makes DTF printing technology an ideal solution for custom apparel printing, catering to diverse customer needs in the fashion market.

What are gang sheets and how do they improve DTF transfer efficiency?

Gang sheets are a DTF printing technique that allows multiple designs to be printed on a single transfer sheet. This method enhances DTF transfer efficiency by optimizing material usage, lowering production costs, and facilitating faster processing times, which is critical for businesses scaling their custom apparel offerings.

What advantages do DTF Transfers offer over traditional printing methods?

DTF Transfers provide several advantages over traditional printing methods, including superior color vibrancy, the ability to print intricate designs, lower production costs through waste reduction, and quicker turnaround times. These benefits make DTF printing technology a game-changer in custom apparel printing, enhancing creativity and efficiency.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | Print designs onto a special film, which is then applied to fabric using heat and pressure, allowing vibrant colors and intricate details. |

| Key Developments | 1. **EazyDTF expands capacity** – Significant investment in large-format DTF printing technology allowing same-day shipping. 2. **Introduction of Snuggle DTF** – A web-to-print platform that simplifies the DTF transfer process for businesses. 3. **Understanding Gang Sheets** – Multiple designs printed on one transfer sheet for optimized material usage and lower production costs. |

| Impact on Apparel Industry | DTF transfers provide rapid iteration, support for seasonal trends, and enhanced customization opportunities, enabling businesses to stand out. |

Summary

DTF Transfers are significantly transforming the apparel industry by introducing a groundbreaking method for custom garment printing. This innovative technology not only enhances the quality and speed of production but also increases accessibility for designers and businesses alike. With the ability to produce intricate, high-quality prints efficiently, companies can meet diverse market demands swiftly, allowing for quicker turnarounds and greater creative freedom. Advancements such as EazyDTF’s increased capacity, Snuggle DTF’s easy access for newcomers, and the implementation of gang sheets have further established DTF as a cost-effective and versatile printing option. As more businesses embrace DTF Transfers, they are poised to elevate their printing capabilities, making this technology an essential component of contemporary apparel production strategies.