DTF transfers, short for Direct to Film transfers, have become a game-changer in high-quality DTF printing, particularly for custom apparel. This innovative printing process allows for vibrant and durable designs that can be applied to a variety of fabrics, making it perfect for the growing market of personalized products. As businesses seek cost-effective printing solutions to meet consumer demands, DTF printing technology stands out for its versatility and quality. Additionally, with the emphasis on sustainable DTF printing practices, such as using eco-friendly inks, this method aligns with the changing preferences of environmentally-conscious consumers. In this article, we will delve into the world of DTF transfers, exploring their benefits and how they can help elevate your brand in today’s competitive landscape.

The concept of Direct to Film printing, often referred to as DTF printing or transfer printing, has garnered attention for its application in custom designs and apparel manufacturing. This state-of-the-art printing technology utilizes films to create intricate designs that are easily transferred onto textiles, ensuring vibrant results that last. Emerging as a favorable option due to its sustainability and cost-effectiveness, this method is revolutionizing the printing industry with its innovative techniques. As businesses increasingly pivot toward delivering tailored experiences, utilizing high-quality DTF transfers can significantly enhance product offerings. Today, we will explore the significance of DTF technology and its impact on modern printing solutions.

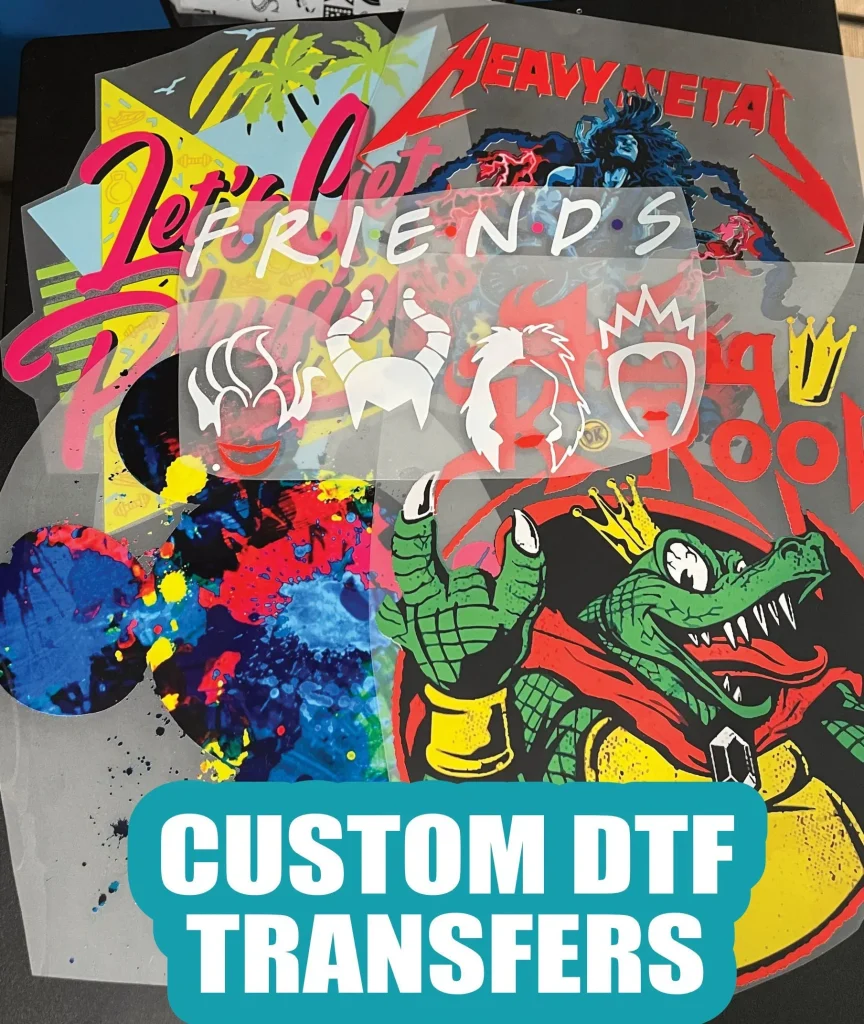

What Are DTF Transfers?

DTF transfers, or Direct to Film transfers, represent a cutting-edge method in custom printing. This technology allows businesses to print vibrant, high-quality designs directly onto film, which are then heat transferred onto fabrics. The versatility of DTF transfers is a significant advantage, as they can be applied to a variety of textiles including cotton, polyester, and blends. This flexibility makes DTF printing an ideal choice for businesses looking to produce customized apparel, promotional items, and merchandise tailored to their customers’ needs.

The process of DTF printing itself is relatively straightforward and can be easily integrated into most printing workflows. Once the design is printed onto the film, it is coated with a special adhesive powder, which is then heated to bond the print with the fabric during application. This method not only ensures vibrant colors and fine details but also offers excellent durability, making it suitable for items that will undergo regular washing and usage. By understanding DTF transfers, businesses can tap into a powerful tool that enhances product offerings and customer satisfaction.

The Benefits of High-Quality DTF Printing

High-quality DTF printing brings numerous benefits to businesses, elevating them above competitors in a crowded market. One of the foremost advantages is the brilliant color quality output that DTF technology produces. The process allows for an impressive range of colors and gradients, ensuring that designs are rendered accurately and vibrantly. This attention to color can significantly enhance the perceived value of products, making them more appealing to consumers looking for unique and high-quality items.

In addition to superior color vibrancy, durability is a key benefit of DTF printing. High-quality DTF transfers bond effectively with fabrics, resulting in prints that resist fading and peeling over time. This means that customers can wear and wash their DTF printed goods without worrying about wear and tear, which is a strong selling point in the apparel market. Thus, by choosing high-quality DTF printing, businesses can not only improve product quality but also build stronger customer relationships by offering reliable and long-lasting products.

Sustainable Practices in DTF Printing

Sustainability is becoming increasingly important for consumers, and businesses are adapting their practices to meet this demand. DTF printing technology is evolving to include environmentally friendly methods, such as the use of water-based inks that minimize harm to the environment. These inks not only provide excellent print quality but also align with the growing trend of eco-conscious purchasing among consumers.

Moreover, companies are beginning to utilize recyclable films in their DTF processes, which reduces waste and promotes a more sustainable production cycle. By adopting sustainable practices in DTF printing, businesses can enhance their brand image and appeal to eco-conscious customers. This not only aligns their operations with current market trends but can also positively impact customer loyalty and retention.

Cost-Effectiveness of Custom DTF Transfers

One of the standout features of DTF printing technology is its cost-effectiveness, particularly for small businesses and startups. Unlike traditional screen printing methods that often incur high setup fees and are less viable for small batch orders, DTF transfers can be produced at a lower cost, even in limited quantities. This affordability makes it easier for businesses to explore customization options without risking significant financial investment.

In addition, the ability to produce high-quality prints on demand allows for greater flexibility in inventory management. Businesses can respond to changing market trends or customer requests without the burden of overproducing, further enhancing their cost efficiency. Overall, DTF printing not only enables high-quality output but also empowers businesses to make smart financial decisions that can lead to increased profitability.

Recent Advancements in DTF Printing Technology

The DTF printing landscape continues to evolve with significant advancements in technology that enhance overall print quality and efficiency. Recent innovations in ink formulations have resulted in better adhesion and brighter colors, substantially improving the vibrancy and longevity of DTF prints. These modern inks are designed specifically for the needs of DTF printing, ensuring that they deliver crisp images and maintain color integrity even after multiple washes.

Additionally, improvements in transfer adhesive formulations have made DTF prints softer and more comfortable against the skin. This focus on both quality and user experience is essential in industries like apparel, where the tactile feel of a garment can impact customer satisfaction. As these advancements come to market, businesses leveraging the latest DTF technology can set themselves apart by offering superior products that meet the high expectations of discerning consumers.

Best Practices for Maximizing DTF Printing Potential

To fully tap into the potential of DTF transfers, businesses should adopt best practices that enhance their production processes and outcomes. A key aspect is investing in high-quality printing equipment that supports high DPI capabilities, ensuring that every print is vibrant and detailed. Additionally, staying current with design software and trends will help businesses create appealing graphics that resonate with their target audience. Regular design reviews and updates can keep offerings fresh and engaging.

Moreover, ongoing employee training is essential to maintaining a high standard of output in DTF printing. By providing staff with education on the latest techniques and tools, businesses can improve operational efficiency and enhance print quality. Finally, engaging in effective marketing strategies will help businesses to showcase their DTF capabilities, attracting new customers and driving sales by highlighting unique product offerings.

Frequently Asked Questions

What are DTF transfers and how do they differ from other printing methods?

DTF transfers, or Direct to Film transfers, utilize a unique printing technology that allows ink to be printed onto a film, which is then applied to fabric using heat and pressure. Unlike traditional screen printing, DTF provides vibrant colors and excellent durability while being versatile enough for various fabric types, making it ideal for customized apparel and promotional items.

Why are high-quality DTF transfers essential for my business?

High-quality DTF transfers are crucial for businesses as they produce vibrant designs that stand out and endure through multiple washes. The durability and clarity of prints can enhance customer satisfaction, leading to positive reviews and repeat business. By incorporating high-quality DTF printing, you ensure your products meet consumer expectations in today’s competitive market.

Can I achieve sustainable DTF printing for my business?

Yes, sustainable DTF printing is achievable by using water-based inks and recyclable films. Many DTF manufacturers are focusing on eco-friendly practices, which not only help the environment but also enhance your brand’s reputation. By adopting sustainable processes in DTF printing, you can attract eco-conscious consumers.

What are the cost benefits of using DTF printing technology?

DTF printing technology is highly cost-effective, especially for small runs or custom orders, compared to traditional screen printing. It reduces costs associated with outsourcing and offers greater production control. Investing in DTF technology allows businesses to fulfill custom requests without compromising on quality or overspending.

How can custom DTF transfers benefit my clothing line?

Custom DTF transfers allow you to create unique and personalized designs for your clothing line, enhancing brand identity. The ability to print on various fabrics with high durability means your apparel can feature intricate designs that won’t fade over time, attracting more customers and setting your products apart from competitors.

What factors should I consider when investing in DTF printing equipment?

When investing in DTF printing equipment, consider factors such as print quality (look for high DPI capabilities), types of inks (preferably eco-friendly), and the machine’s versatility to handle different fabric types. Additionally, ensure that the equipment supports the latest DTF printing technology to keep your output on the cutting edge.

| Key Point | Description |

|---|---|

| Versatility | DTF transfers can print on various materials like cotton and polyester. |

| Vibrant Colors | Produces striking color prints that attract customer attention. |

| Durability | High-quality transfers resist peeling and fading, ensuring longevity. |

| Market Growth | Increasing demand for customized items drives DTF technology adoption. |

| Technological Advancements | Innovations improve print quality, durability, and adhesive properties. |

| Cost Efficiency | More economical than traditional printing, benefiting small businesses. |

| Sustainability | Emerging use of eco-friendly inks and recyclable films. |

| Best Practices | Investing in equipment, design strategy, and marketing can optimize results. |

Summary

DTF transfers offer an innovative solution for businesses aiming to maximize their potential. This advanced printing technique not only provides stunning colors and durable finishes but also caters to the growing demand for customization in today’s market. By leveraging DTF technology, companies can meet consumer preferences effectively while enhancing their competitive edge. As the sector evolves, businesses that prioritize quality, sustainability, and effective marketing strategies will thrive, ensuring a meaningful impact in a burgeoning industry.