DTF transfers, or Direct to Film transfers, are transforming the landscape of custom apparel with their innovative approach to printing. This beginner-friendly method allows aspiring designers to create intricate and vibrant designs that can be easily transferred onto various fabrics. By utilizing DTF printing techniques, you can unlock a world of creative possibilities for your clothing line or personal projects. Whether you’re just starting out or looking to enhance your printing skills, this guide serves as a comprehensive resource on how to do DTF transfers effectively. From selecting the necessary equipment for DTF printing to mastering the application process, we’ll cover everything you need to know in this detailed DTF transfer tutorial.

Often referred to as film-based printing for garments, DTF transfers represent a groundbreaking shift in how we approach custom textile design. This technology streamlines the process of transferring detailed artwork onto fabrics, making it an attractive option for newcomers to the apparel customization scene. As you navigate the beginner’s guide to DTF printing, you’ll find a wealth of information on the essential tools and techniques required to succeed. The versatility of this transfer method caters to a wide range of fabrics, ensuring that your creations always pop with color and detail. Dive into this exciting world of DTF printing and discover how it can elevate your design projects to new heights.

Understanding DTF Printing Technology

DTF printing, or Direct to Film printing, is revolutionizing the way custom designs are printed on apparel. This technology uniquely allows for designs to be printed on a special film, preserving color quality and enabling intricate details to be transferred easily. What sets DTF apart from other methods like traditional screen printing is its ability to produce vivid, high-resolution graphics that remain durable through washes and wears. By using water-based inks, DTF aligns with eco-friendly practices, making it a sustainable choice for both producers and consumers.

As a result, DTF printing caters to a broad spectrum of fabric types, from cotton to polyester blends, allowing for creative freedom. The adaptability of this technology means that not only can individual artists achieve professional results, but businesses can also upscale their production without compromising on quality. By understanding DTF printing technology, creators can leverage its unique capabilities to elevate their custom apparel offerings.

Essential Equipment for DTF Transfers

To kick off your DTF printing journey, investing in essential equipment is a must. The heart of the operation is the dedicated DTF printer, which is specifically designed to print images onto transfer film. Selecting a reliable printer is crucial as it affects the printing quality significantly. Additionally, adhesive powder is vital as it helps bond the print with the fabric during the heat transfer process, ensuring a long-lasting finish.

It is also important to own a quality heat press. This equipment is used to transfer designs from the film to the fabric reliably. For beginners, a user-friendly heat press can make the transfer process more intuitive. By understanding the role of each piece of equipment in the DTF printing setup, users can make informed decisions that enhance their printing experience and outcomes.

Step-by-Step Guide to Creating DTF Transfers

Creating DTF transfers involves a series of straightforward steps, making it accessible even for beginners. Start with the design creation using graphic design software like Adobe Illustrator or CorelDRAW. It is essential to configure your software settings to align with DTF standards to ensure optimal results. After your design is set, print it using your DTF printer, adjusting the settings appropriately for the transfer film.

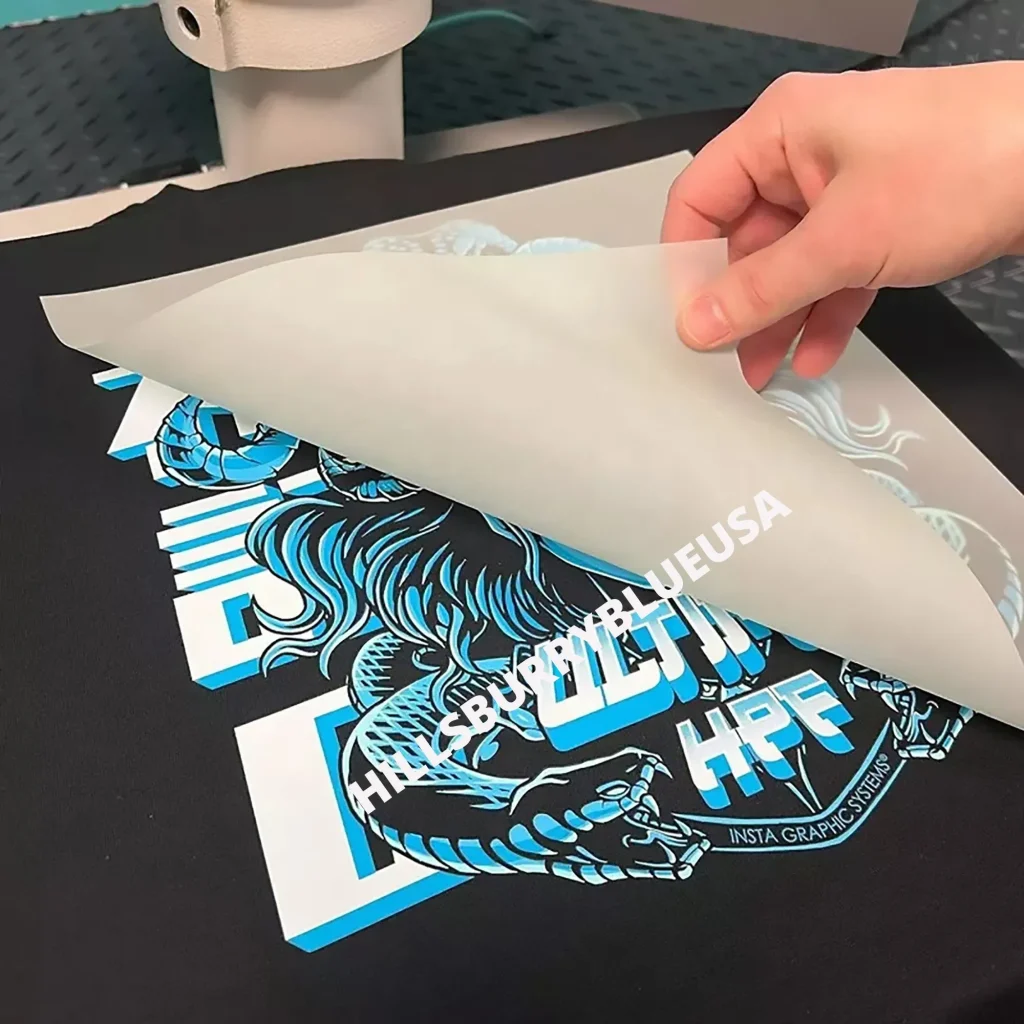

Once the design is printed, the next step is the application of adhesive powder. This is done while the print is still wet, allowing for even distribution across the design. The crucial stage is curing the print under controlled heat, ensuring that the adhesive activates properly. Finally, the transfer is completed using a heat press, where precision is critical for achieving a vibrant and durable print on the fabric. This step-by-step process highlights the simplicity and effectiveness of DTF transfers.

The Benefits of Using DTF Transfers

The advantages of DTF printing are numerous, particularly for those venturing into custom apparel. One of the most significant benefits is the vibrancy of colors achieved through this method, allowing designs to pop on any fabric. DTF transfers are also known for their ability to work on various textiles, including challenging materials like hoodies and hats, which are often less compatible with traditional printing methods.

Moreover, the straightforward setup process associated with DTF printing makes it an inviting option for beginners. This method reduces the time and effort typically required for traditionally intricate printing processes, enabling quicker turnaround times and increased productivity. By choosing DTF transfers, newcomers to apparel printing can efficiently produce high-quality, eye-catching designs.

Common Challenges and Expert Advice for DTF Printing

While the DTF printing process is generally user-friendly, beginners may encounter some challenges. One common issue is achieving consistency in the curing process, as varying pressure and temperature settings can yield different results across fabric types. To counter this, it is essential to record your settings and make adjustments based on your experience with specific materials.

Maintaining equipment, especially the DTF printer and heat press, is another challenge to consider. Regular cleaning and servicing can prolong the lifespan of your machines and ensure consistent quality prints. Additionally, leveraging online tutorials and forums can provide vital support and tips from experienced users, helping to navigate the common pitfalls of DTF printing.

Resources and Community Support for DTF Enthusiasts

For those eager to enhance their DTF transfer skills, a wealth of resources is available online. Platforms like YouTube host various tutorials specifically tailored for beginners, offering visual guidance to navigate the DTF printing process effectively. Search for keywords like ‘DTF transfers tutorial for beginners’ to find comprehensive guides that break down each step.”},{

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a modern printing technique used in custom apparel. The process involves printing your design onto a special film using a DTF printer. The design is then transferred to fabric using heat and adhesive powder, resulting in vibrant, durable prints on various materials.

What equipment is necessary for DTF Printing?

To begin with DTF printing, you will need essential equipment such as a DTF printer, transfer film, adhesive powder, and a heat press. These components work together to ensure the successful execution of DTF transfers, providing high-quality results.

How to do DTF transfers effectively?

Doing DTF transfers effectively involves several steps: first, design your artwork using graphic design software. Next, print the design on transfer film, apply adhesive powder while the print is still wet, cure the print in an oven, and finally, use a heat press to transfer your design onto the fabric.

What is a beginner’s guide to DTF printing?

A beginner’s guide to DTF printing covers the basics of designing, printing, and transferring images onto fabric. Key steps include selecting the right equipment, creating and printing your design, curing it with adhesive, and applying the final heat transfer for a professional finish.

Are there any tips for successful DTF transfer printing?

Yes! Successful DTF transfer printing requires practice. Focus on perfecting the curing process, maintain your equipment regularly, and consult online tutorials and community support for troubleshooting and technique improvement.

Can I use DTF Transfers on different types of fabric?

Absolutely! DTF transfers are versatile and can be applied to a variety of fabrics, including cotton, polyester blends, and even specialized items like hoodies and hats, making them suitable for diverse custom apparel projects.

| Aspect | Description |

|---|---|

| DTF Printing | Revolutionizes custom apparel printing by transferring directly from a film, using water-based inks for vibrant results. |

| Key Equipment | Necessary tools include a DTF printer, transfer film, adhesive powder, and a heat press. |

| Steps for DTF Transfers | 1. Design creation; 2. Printing; 3. Applying adhesive; 4. Curing the print; 5. Heat transfer. |

| Advantages | Vibrant colors, versatility with fabrics, and simplicity ideal for beginners. |

| Challenges | Notably, mastering curing processes and maintaining equipment can be challenging. |

| Resources | YouTube tutorials, blog guides, and community forums for learning and support. |

Summary

DTF Transfers have become a groundbreaking method in the world of custom apparel, providing innovative solutions for both beginners and seasoned creators. This printing method not only enhances creativity but also offers various advantages that cater to a wide audience, from vibrant colors to fabric versatility. By understanding the key components, mastering the printing process, and utilizing available resources, anyone can successfully embark on their DTF transfers journey. Dive into the world of DTF Transfers, and unlock your potential in custom printing!