DTF Transfers, or Direct to Film transfers, represent a revolutionary advancement in the realm of textile printing, merging creativity with cutting-edge technology. This innovative method allows users to apply vibrant and intricate designs to fabrics in a cost-effective manner, while also ensuring durability and quality. With DTF printing gaining momentum in various industries, it provides remarkable versatility that supports a wide range of fabric types, making it a favorite among designers and businesses alike. The DTF transfer process itself involves a seamless series of steps, from printing on specialized film to the final fabric application, ensuring that each design retains its brilliance over time. As we explore the benefits of DTF transfers, you’ll discover why this method is quickly becoming a staple in the world of apparel decoration and custom printing.

Also known as Direct to Film printing, DTF Transfers have become increasingly popular for their efficiency and high-quality results in fabric decoration. Using advanced DTF printing technology, this process connects artistry with practicality, offering an eco-friendly alternative to traditional printing methods. With a focus on sustainability, DTF transfer applications involve unique film mediums that retain color integrity and withstand wear and tear, making them perfect for all types of textiles. This innovative printing approach is reshaping the landscape of custom apparel production, allowing both businesses and hobbyists to explore creative possibilities with minimal complications. The benefits associated with DTF transfers extend far beyond simple aesthetics, highlighting the growing shift towards modern, environmentally conscious printing solutions.

Understanding DTF Printing Technology

DTF printing technology has revolutionized the world of fabric printing by offering a versatile and high-quality approach to transferring designs onto various materials. Unlike traditional methods that require direct contact with fabric, this innovative technique uses a transfer film coated with special DTF inks which create vibrant and durable images. This process means that printers can achieve the same quality as screen printing or Direct to Garment (DTG) printing, but with greater ease and versatility.

By leveraging the advancements in DTF technology, print service providers can cater to a broader audience, including those seeking highly personalized apparel or unique promotional products. The DTF transfer process is straightforward, allowing for a greater number of designs to be processed simultaneously, making it perfect for both small-scale orders and larger commercial projects.

Frequently Asked Questions

What are the advantages of DTF Transfers over traditional printing methods?

DTF transfers offer several advantages over traditional printing methods, including a more user-friendly process, greater versatility across multiple fabric types, superior durability against wash wear, and cost-effectiveness, especially for smaller runs or custom items.

How does the DTF transfer process work in detail?

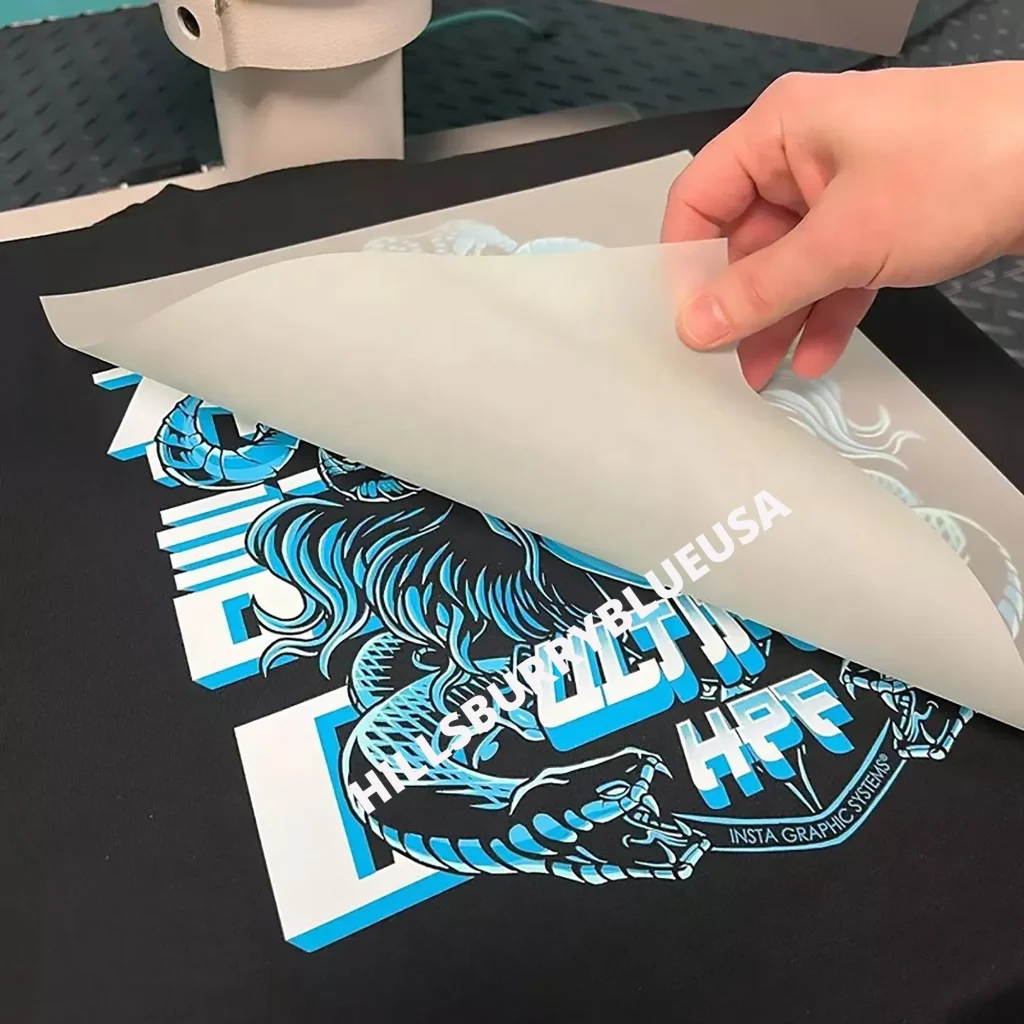

The DTF transfer process involves several steps: first, a design is printed onto a specialized transfer film using DTF printing technology. Next, a powdered adhesive is applied and cured with heat. Finally, the film is transferred to the fabric using a heat press, allowing the design to bond securely to the material.

What types of fabrics can DTF Transfers be applied to?

DTF transfers can be applied to a wide variety of fabrics, including cotton, polyester, cotton-poly blends, and even synthetic materials like nylon. This makes DTF printing technology particularly versatile for custom apparel and textile projects.

Is DTF printing eco-friendly?

Yes, DTF printing is considered eco-friendly as it primarily utilizes water-based inks and does not involve harsh solvents that are harmful to the environment. This makes DTF transfers a safer and more sustainable choice for textile printing.

What industries can benefit from DTF transfers?

Various industries can benefit from DTF transfers, including the apparel industry, promotional item production, personalized gifts, and small to medium-sized businesses looking for cost-effective textile decoration solutions. Their versatility and quality make them suitable for many applications.

How does the durability of DTF transfers compare to other methods?

DTF transfers are known for their remarkable durability. Compared to other methods like Direct to Garment (DTG) or screen printing, DTF prints can withstand numerous washes with minimal fading, cracking, or peeling, making them ideal for clothing that sees frequent use.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | DTF transfers utilize a unique film medium to transfer high-quality prints onto fabric using eco-friendly, water-based inks. |

| How Does the DTF Process Work? | The DTF process involves printing on film, applying powder adhesive, curing the adhesive, and finally transferring the design to fabric using heat. |

| Benefits of DTF Transfers | DTF transfers are versatile, durable, cost-effective, and simplify the printing process, making them an excellent choice for a variety of fabrics and applications. |

| Market Trends (2023-2025) | The DTF sector is growing, with increased adoption among businesses, technological advancements enhancing quality, and a focus on sustainability driving demand. |

Summary

DTF Transfers represent a revolutionary approach in textile printing, combining vibrant design capability with eco-friendliness. This innovative method stands out due to its durability and versatility across various fabric types. As this technology continues to evolve, an increasing number of businesses are likely to adopt DTF Transfers for cost-effective and high-quality printing solutions. With significant benefits such as simplified operations and sustainability, DTF Transfers are not just a trend, but a transformative step forward in the realm of fabric decoration.