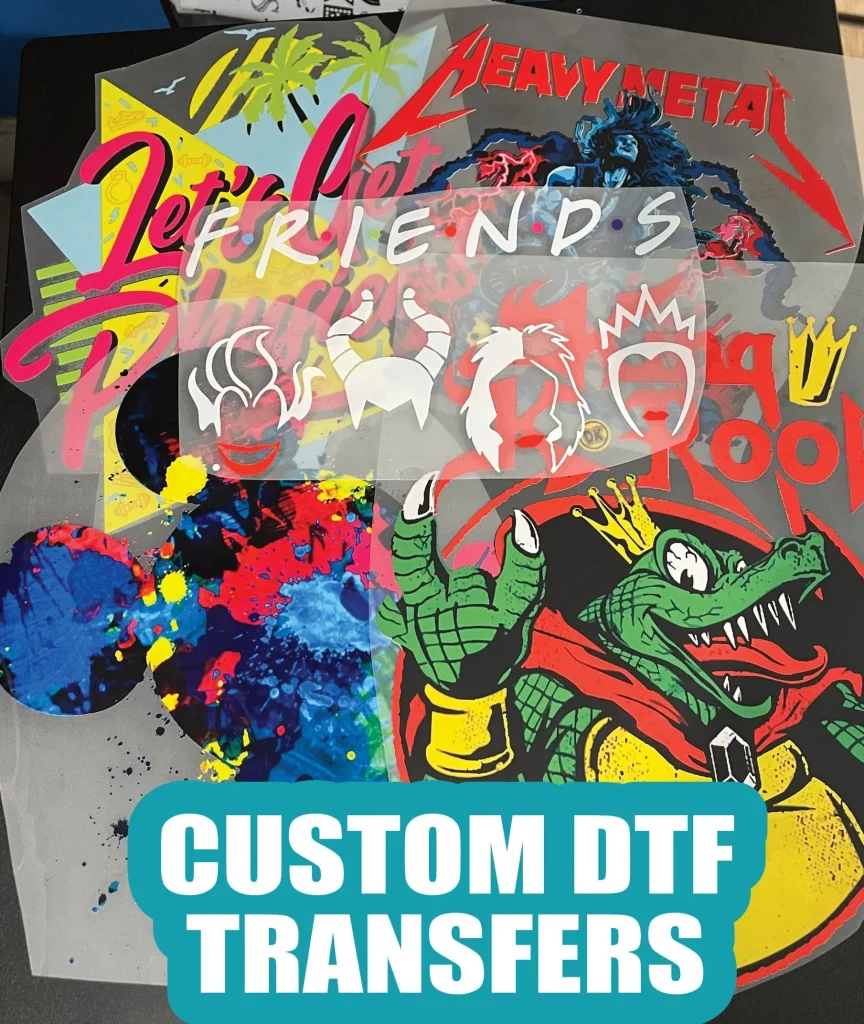

DTF transfers, or Direct to Film transfers, are rapidly transforming the landscape of custom apparel printing in 2023. This innovative printing technology allows for vibrant designs to be printed directly onto a film before being transferred to fabric, resulting in high-quality images that are both durable and striking. With the DTF printing process, users can achieve intricate designs with ease while enjoying the significant advantages such as versatility and cost-effectiveness. As businesses increasingly adapt to the latest 2023 printing trends, DTF transfers are proving to be a valuable addition, enabling them to meet the customization demands of their clientele. Understanding the benefits of this technique positions print shops and entrepreneurs alike to capitalize on the burgeoning market for unique apparel products.

In the realm of textile printing, the emergence of film-based transfer technologies has opened new avenues for creative expression and business opportunities. Referred to as transfers printed directly onto film, this method is gaining traction among custom clothing makers and enthusiasts alike. Not only does this approach allow for detailed designs, but it also offers a range of benefits, including faster production times and adaptability to various fabric types. As this printing revolution progresses throughout 2023, innovations such as eco-friendly inks and smart printing solutions are shaping the future, ensuring that businesses can compete effectively in a dynamic market. By exploring these advanced techniques, both established companies and newcomers can optimize their offerings and meet the evolving demands of consumers.

Understanding DTF Transfers: A Game Changer in Apparel Printing

DTF transfers, or Direct to Film transfers, represent a groundbreaking advancement in the realm of textile printing. They offer a sophisticated alternative to traditional methods, allowing for intricate designs to be applied to various fabric types quickly and efficiently. By leveraging a unique printing technology, DTF not only guarantees vivid colors but also detailed renderings, which are essential for contemporary custom apparel printing. This innovative method has positioned itself as a favorite among businesses looking to stay ahead in the competitive apparel market.

The exceptional quality provided by DTF transfers is largely attributed to its use of white ink, which significantly enhances color opacity, especially on darker fabrics. Moreover, the application of powdered adhesive directly onto the film ensures robust adhesion to fabric surfaces. As designers and entrepreneurs seek cutting-edge techniques for their textile projects, DTF transfers stand out as a viable solution, blending high-quality output with operational efficiency.

The DTF Printing Process: Step-by-Step Insights

The DTF printing process comprises a systematic sequence of steps that contribute to its overall efficacy as a transfer method. At the heart of this process is the specialized DTF printer, which is capable of rendering high-resolution designs onto a transparent film. This initial stage is crucial since it dictates the vibrancy and detail of the final product. Following the printing, the application of powdered adhesive ensures that the design adheres strongly during the transfer process.

After the film has been printed and adhesive applied, heat and pressure are employed to firmly affix the design onto the chosen fabric. This transfer phase is critical as it not only activates the adhesive but also guarantees that the print can withstand wear and washing. In a landscape where personalization is key, understanding this process can empower small businesses and larger enterprises alike to optimize their custom apparel offerings and meet consumer demands effectively.

Exploring the Advantages of DTF Transfers for Custom Apparel

DTF transfers boast an array of advantages that have sparked increased interest among businesses for custom apparel printing. One of the foremost benefits is the ability to produce high-quality prints that feature vibrant colors and intricate details, enhancing the overall look of the apparel. These attributes, combined with exceptional durability, make DTF an ideal choice for apparel meant to last, thus appealing to consumers who prioritize quality.

Versatility further underscores DTF’s appeal; it can be applied to a wide range of fabric types, which means businesses can cater to varying customer preferences and styles. Additionally, DTF transfers present a cost-effective solution for startups and small businesses. With lower equipment costs compared to other methods like Direct to Garment (DTG) printing, DTF allows these enterprises to produce customized apparel effectively and affordably, striking a harmonious balance between quality and expense.

Market Growth and Demand for DTF Transfers in 2023

The demand for DTF transfers has soared, and the market has experienced notable growth as businesses recognize the benefits of this innovative printing technology. The appetite for custom apparel has significantly influenced this trend, with consumers increasingly seeking unique and personalized clothing options. As a result, more businesses are utilizing DTF to create distinctive designs that attract attention and meet consumer demands for originality.

Another driving force behind the market growth is the entry of small businesses into the custom printing sphere. With DTF technology, these businesses can offer personalized products that rival those of larger companies without the steep investment associated with other modern printing methods. This democratization of technology fosters competitive practices and drives innovation in the apparel printing sector.

Current Trends Shaping DTF Printing in 2023

As we delve into 2023, several trends are shaping the landscape of DTF printing. One of the most pronounced trends is the integration of advanced technologies that enhance production efficiency. Faster machines and improved printing techniques are enabling businesses to produce higher volumes quickly while maintaining quality standards, allowing them to meet the increasing demand for custom apparel.

Another key trend is the growing emphasis on eco-friendly practices within the DTF printing industry. As sustainability becomes a focal point for consumers and corporations alike, environmentally friendly inks and materials are gaining traction among manufacturers. This shift not only caters to responsible consumerism but also positions businesses favorably in an increasingly conscious market, providing another layer of relevance to DTF technology.

Navigating Challenges in the DTF Transfer Landscape

Despite the numerous advantages DTF transfers offer, the technology is not without its challenges. One significant hurdle is the competition faced from other established printing methods such as Direct to Garment (DTG) and screen printing. These alternatives have a well-established presence and consumer trust, which can make it difficult for DTF to carve out its niche in specific markets. Businesses must find ways to differentiate their offerings and emphasize the quality and versatility of DTF transfers.

Additionally, proper training is essential for anyone working with DTF technology. Understanding how to operate the printers and manage materials correctly can make a considerable difference in the quality of the final product. Therefore, providing adequate training resources is necessary for minimizing production errors and ensuring that businesses can uphold consistent quality across various print runs.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process involves three main steps: First, a special DTF printer prints the desired design onto a film. Next, a powdered adhesive is applied while the ink is still wet to ensure effective bonding. Lastly, the film is heat-pressed onto the fabric, activating the adhesive and transferring the design. This method leads to high-quality prints that are vibrant and durable.

What are the key advantages of using DTF transfers in custom apparel printing?

DTF transfers offer numerous advantages, including the ability to produce vibrant colors and intricate details on various fabric types, from cotton to blends. They are cost-effective, especially for small businesses, and allow faster production times. Additionally, DTF technology simplifies the printing process, making it an ideal choice for custom apparel printing.

How has the market for DTF transfers grown in 2023?

In 2023, the DTF transfer market has experienced significant growth due to the rising demand for custom apparel. Many businesses are adopting DTF technology for its ability to create unique designs efficiently and compete with larger enterprises without heavy investments in equipment.

What are some current 2023 printing trends associated with DTF printing?

Current trends in DTF printing include technological integration for faster production, a focus on eco-friendly materials and inks due to growing sustainability concerns, and an emphasis on personalized solutions that cater to consumer demands for customization in apparel.

What challenges do businesses face when using DTF transfers?

While DTF transfers have many benefits, businesses face challenges such as competition from established printing methods like DTG and screen printing. Additionally, the need for proper training on DTF equipment is crucial to achieve high quality, and consistent quality assurance across runs can also be challenging.

Why should businesses consider DTF transfers for their printing needs in 2023?

Businesses should consider DTF transfers in 2023 due to their versatility and ability to produce high-quality, cost-effective custom designs. With the growing trend for personalized apparel and advancements in printing technology, DTF provides an efficient solution that can help businesses stand out in a competitive market.

| Aspect | Details |

|---|---|

| Definition | DTF transfers are an innovative printing technology that allows designs to be transferred onto various fabrics using a special film. |

| Printing Process | 1. Printing the design onto the DTF film using a special printer. 2. Applying adhesive to the wet ink. 3. Transferring the film onto the fabric using heat and pressure. |

| Advantages | High-quality prints, versatility across fabric types, cost-effectiveness for small businesses, and faster production times. |

| Market Growth | Increasing demand for custom apparel has led to significant growth in the DTF transfer market, allowing small businesses to thrive. |

| Current Trends | Technological advancements, eco-friendly practices, and customization options are shaping the DTF printing landscape in 2023. |

| Challenges | Competition from established printing methods, the need for proper training, and ensuring consistent quality across production runs. |

Summary

DTF transfers are transforming the fabric printing industry by offering a unique and effective solution for custom designs on various textiles. This innovative technology combines high-quality output with cost-efficiency, making it an ideal choice for both new and established businesses. With ongoing advancements in printing technology, eco-friendly practices gaining traction, and the focus on customization, DTF transfers are poised to meet the demands of today’s apparel market. However, businesses must navigate the competitive landscape and invest in proper training to maintain quality and efficiency in production. Overall, DTF transfers are paving the way for enhanced creativity and sustainability in textile printing.