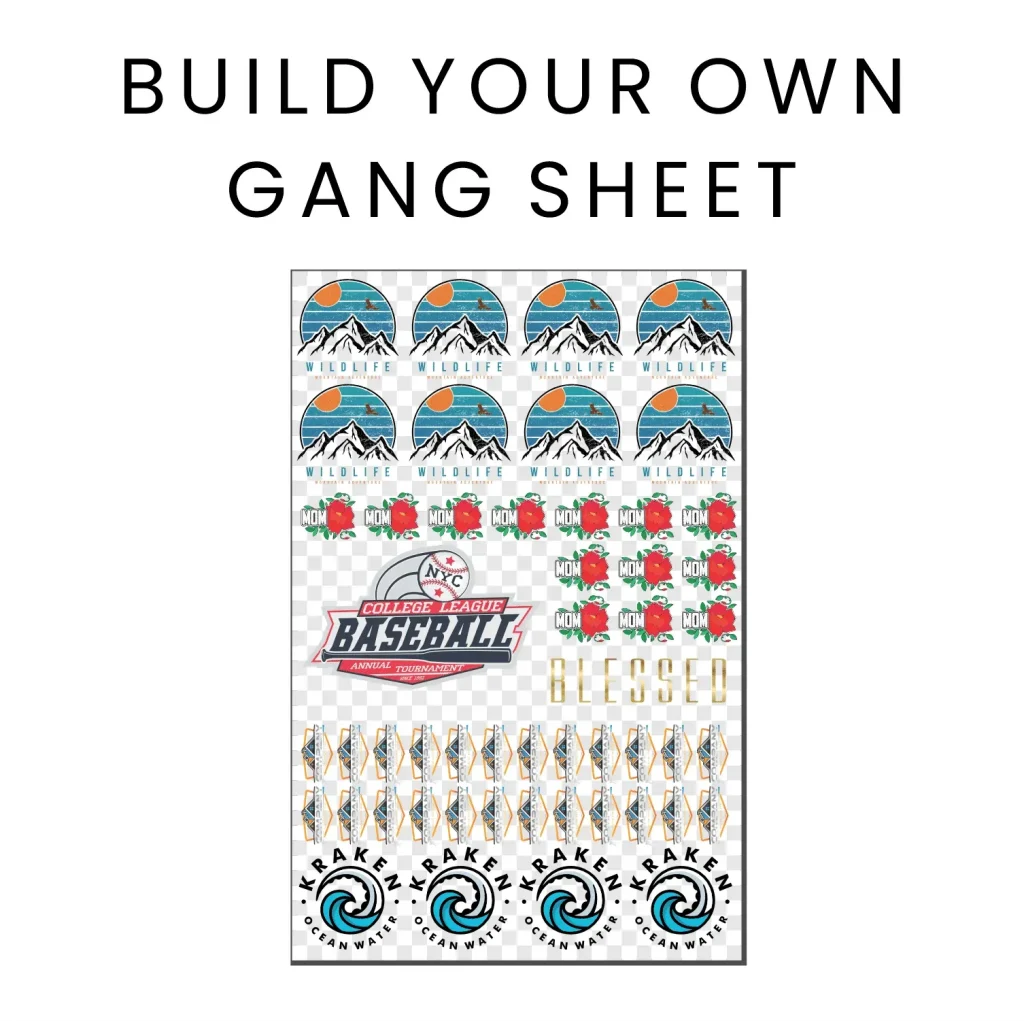

The DTF Gangsheets Builder is an essential tool in the realm of Direct To Film (DTF) printing, empowering users to create intricate designs efficiently. By optimizing design layouts, businesses can maximize their output while minimizing waste, making gangsheets an invaluable resource in the garment printing industry. Using effective DTF printing tips such as proper color management techniques and strategic positioning on sheets, users can enhance print quality and streamline production processes. Mastering the DTF Gangsheets Builder leads to faster turnaround times and superior results, ensuring that your custom apparel stands out in a competitive market. Whether you’re looking to refine your skills or innovate your workflow, understanding the fundamentals of this builder will set you on the path to success.

The Direct To Film Gangsheets Builder is a crucial innovation for those involved in garment decoration and custom apparel printing. This tool simplifies the intricate process of gangsheets printing, allowing multiple designs to be printed on one sheet of film, which drastically reduces material waste and production costs. By leveraging advanced techniques for design layout optimization and color management in DTF printing, users can achieve exceptional results and maintain aesthetic integrity in their apparel. Moreover, the functionality of various DTF printer models plays a significant role in the overall performance of prints, making it essential for users to stay informed about their equipment capabilities. Understanding these elements can greatly enhance the efficiency and quality of your printing operations.

Mastering Design Layout Optimization in DTF Printing

Design layout optimization is crucial in DTF printing, where space is at a premium. By arranging multiple designs on a single gangsheets, you ensure efficient use of materials, thereby reducing waste. Key factors in layout optimization involve the strategic placement of graphics, ensuring that they fit well within the designated bleed areas to avoid cutting errors. Additionally, it’s vital to group similar designs to make the most of available space, leading to both cost efficiency and a streamlined workflow.

Moreover, understanding the dimensions of your printing medium will allow for more precise design placements. A well-optimized layout can significantly influence the print quality, as inadequate spacing might lead to misalignment during the printing process. Utilizing software tools that cater specifically to the DTF Gangsheets Builder can guide you in adhering to dimensional guidelines, allowing for a balanced and professional finish.

Effective Color Management Techniques for DTF Printing

Color management plays a pivotal role in achieving vibrant and accurate prints in DTF printing. Ensuring that your design is created in CMYK color mode is a fundamental step because DTF printers operate with these inks for color reproduction. Using RGB can lead to discrepancies in color appearance when transferred to fabric. Therefore, understanding color profiles and how they correspond to your DTF printer’s capabilities is essential for any successful print job.

In addition to selecting the right color mode, it’s important to consider the substrate on which the print will be applied. Different fabrics absorb colors differently, impacting the final output’s vividness. Implementing color calibration processes within your workflow and consistently conducting tests on similar fabrics can greatly improve your color accuracy and consistency, ensuring that each print meets or even exceeds your expectations.

Utilizing Templates for Streamlined DTF Gangsheets Creation

Incorporating templates in your DTF printing process can tremendously streamline production and maintain quality across various projects. Many software platforms and online DTF Gangsheets Builders offer customizable templates that cater to common design requirements. This not only saves time in the design phase but also guarantees adherence to print specifications that might otherwise be overlooked when designing from scratch.

Moreover, using templates allows for consistent branding, as you can ensure that all designs share similar dimensions, color palettes, and design elements. This consistency is particularly vital for businesses looking to produce a cohesive product line, as it reinforces brand identity and makes it easier for customers to recognize their brand’s style. Templates also serve as a great starting point, allowing designers to focus on creative elements without worrying about the technical details of layout.

Advanced Layering Techniques for Quality DTF Prints

Layering techniques in DTF printing can vastly enhance the quality of your prints, adding depth and detail. By grouping colors and designs into layers, you optimize ink usage while also ensuring that the final print exhibits cleaner lines and a more professional finish. Implementing layering strategically can lead to improved durability of the print, as the method can minimize blotching and enhance the adherence of inks to the film.

Additionally, understanding the science behind ink application during the layering process can provide insight into how different colors interact. For instance, layering similar color pigments can enhance vibrancy, while contrasting colors can create eye-catching designs. Emphasizing this technique in your DTF printing workflow not only improves aesthetic quality but also optimizes operational efficiency by reducing the amount of ink consumed.

Pre-Print Checks for Ensuring DTF Print Quality

Conducting thorough pre-print checks is a non-negotiable step when working with DTF printing. These checks help avoid costly mistakes that can arise during the printing process, which can lead to wasted materials and time. Key areas to focus on include the resolution of designs, ensuring they meet the print specifications of the DTF printer, as well as verifying the bleed areas around each design to avoid cutting inaccuracies.

Furthermore, file type compatibility is also critical; commonly used formats like PNG and TIFF are preferred for their high-quality outputs. Implementing a checklist to review these elements before initiating the print job can drastically enhance reliability and outcome consistency. It’s also advisable to perform test prints whenever introducing new designs or changing materials, ensuring your pre-press conditions are always optimal.

Maintaining Equipment for Optimal DTF Printing Performance

Regular maintenance of DTF printing equipment is essential to ensure optimal performance and prolong the lifespan of your printer. Consistency in cleaning and servicing your printer can significantly affect the print quality; clogged nozzles and dirty inks can cause inconsistent colors and poor image sharpness. Following the manufacturer’s guidelines for maintenance practices will provide a clearer understanding of how to care for your specific equipment properly.

Moreover, implementing a routine maintenance schedule can prevent common issues that lead to downtime. Keeping an inventory of essential cleaning supplies, such as cleaning solutions and replacement parts, can also streamline the upkeep process, helping to ensure that your DTF Gangsheets Builder operates efficiently at all times. Ultimately, a well-maintained machine is key to achieving high-quality prints and maximizing productivity in any printing operation.

Frequently Asked Questions

What is the importance of using the DTF Gangsheets Builder in garment printing?

The DTF Gangsheets Builder is essential for garment printing because it allows users to print multiple designs on a single sheet of film, optimizing material usage and reducing waste. This leads to cost savings and increased efficiency in production, which is crucial given the rising demand for custom apparel.

How can I optimize my design layout when using the DTF Gangsheets Builder?

To optimize your design layout in the DTF Gangsheets Builder, strategically position designs to maximize sheet space, ensuring they are not too close to edges. Adhere to recommended dimensions for each design, as this is critical for maintaining print quality and preventing cutting issues during the printing process.

What are the key color management tips for DTF printing?

When using the DTF Gangsheets Builder, proper color management is crucial. Always design in CMYK mode if your printer uses CMYK inks, as RGB can lead to color mismatches in the final print. This ensures accurate color reproduction, vital for high-quality DTF printing results.

How can templates assist in using the DTF Gangsheets Builder effectively?

Templates help streamline the design process within the DTF Gangsheets Builder by providing pre-made layouts that meet print specifications. By using and customizing templates for common items, users can save time and ensure consistency across multiple projects, improving the overall printing experience.

What pre-print checks should I conduct when using the DTF Gangsheets Builder?

Before printing with the DTF Gangsheets Builder, conduct thorough pre-print checks such as verifying that your designs meet the printer’s resolution requirements and ensuring that the bleed area around each design is sufficient. This helps avoid costly mistakes and guarantees a higher quality final print.

Why is maintenance important for DTF printers when using the Gangsheets Builder?

Regular maintenance of your DTF printer is vital for achieving optimal performance and print quality when using the Gangsheets Builder. Consistent upkeep reduces downtime and extends the printer’s lifespan while ensuring that the prints remain sharp and true to design, making maintenance an essential part of the printing process.

| Key Areas | Tips |

|---|---|

| Design Layout Optimization | 1. Position designs strategically on the sheet. 2. Follow recommended dimensions for print quality. |

| Color Management | 1. Design in CMYK mode for accurate color reproduction. 2. Avoid RGB to prevent unexpected color shifts. |

| Use of Templates | 1. Utilize pre-made templates to save time. 2. Customize templates for consistency across projects. |

| Layering Techniques | 1. Group similar colors for efficient ink application. 2. Follow layering procedures for improved print depth and quality. |

| Pre-print Checks | 1. Verify resolution and bleed areas of designs. 2. Ensure compatible file types are used. |

| Maintenance of Equipment | 1. Regular cleaning enhances print quality. 2. Follow manufacturer’s guidelines for optimal performance. |

Summary

DTF Gangsheets Builder is a pivotal tool that can greatly enhance the garment printing process. By mastering its features, including design layout optimization, proper color management, and consistent use of templates, users can maximize efficiency and print quality. Maintaining equipment and performing pre-print checks further ensures that your outputs meet industry standards. As the DTF printing industry continues to advance, staying informed and adapting your techniques will not only keep you competitive but also allow you to elevate your printing endeavors. Incorporate these strategies today to gain a significant edge in your DTF printing projects.