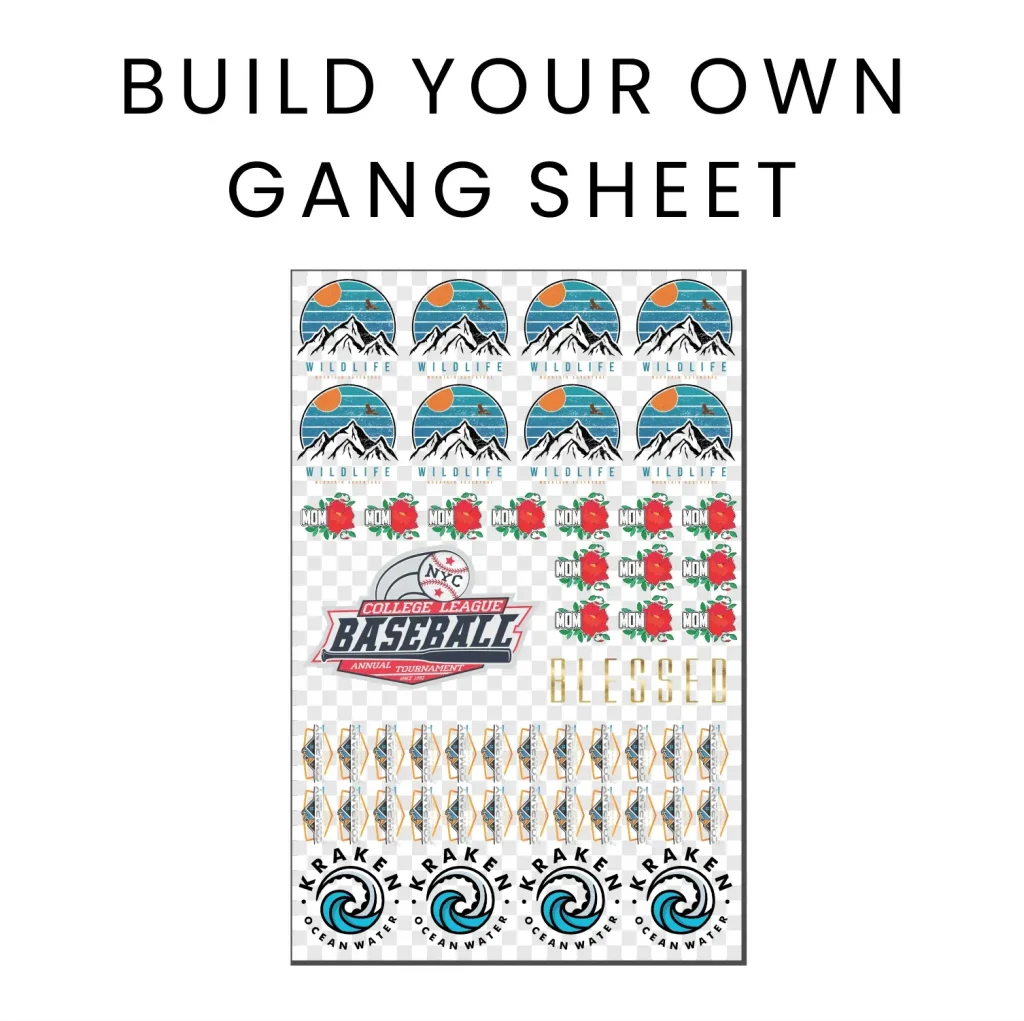

The DTF Gangsheet Builder is a revolutionary tool in the world of printing, particularly for those involved in DTF printing techniques. This builder enhances your workflow by allowing you to efficiently design and produce a variety of transfers suited for textiles. Whether you are a seasoned graphic designer or a newcomer looking for a graphic design tutorial, learning how to use the DTF Gangsheet Builder can significantly elevate your projects. With its intuitive interface and powerful capabilities, you can create stunning prints that maintain vibrant colors and exceptional detail. As you explore the intricacies of heat transfer printing, you’ll find that this innovative software is essential for maximizing your creativity and productivity.

The Direct to Film (DTF) Gangsheet Builder serves as a key resource for artists and businesses alike seeking to master modern printing methods. By utilizing this advanced design tool, users can streamline their gang sheet creation process, ultimately optimizing material usage and enhancing output quality. This guide will clarify the effective implementation of this software, offering insights into various printing techniques that integrate seamlessly with the DTF process. As you navigate through the essentials of setting up and executing your designs, you’ll discover invaluable tips and tricks that can transform your approach to textile transfers. Join us in this graphic design exploration, where every step will empower you to achieve professional-grade results effortlessly.

Maximizing Efficiency with the DTF Gangsheet Builder

Using the DTF Gangsheet Builder not only helps you streamline your workflow but also maximizes the efficiency of your materials. This tool allows you to group multiple designs onto a single sheet, minimizing waste and reducing costs associated with printing. By carefully considering your layout and design arrangement, you can ensure that every inch of film is utilized effectively, thus enhancing your printing process. This focus on efficiency is particularly beneficial for businesses aiming to scale their operations, as it allows for larger print runs without sacrificing quality.

Furthermore, maximizing efficiency with the DTF Gangsheet Builder also involves optimizing your printer settings and media choices. Using high-quality DTF films and inks combined with optimized printer configurations ensures that you achieve vibrant and durable prints every time. Regularly review your printing setup and adjust temperature and pressure settings as necessary to ensure perfect transfers. By incorporating these strategies, you not only improve the overall quality of your final product but also enhance your production speed.

Key Considerations for DTF Printing

When embarking on a DTF printing project, several key considerations can significantly impact the quality of your output. First, it’s vital to choose the right materials, including films and inks that are specifically designed for DTF processes. Utilizing compatible or high-quality materials can prevent issues such as fading or peeling over time, ensuring that your designs maintain their vibrant appearance on garments. Additionally, understanding the specific types of fabrics you will be printing on will influence both your heat settings and ink choices.

Another important consideration is the resolution and quality of your artwork. When preparing designs for the DTF Gangsheet Builder, ensure that they are created at a minimum resolution of 300 DPI. This high resolution ensures that the details of your designs are sharp and clear, resulting in high-quality transfers. Additionally, using the CMYK color model is crucial for achieving accurate color reproduction in your prints. These preliminary steps establish a firm foundation for the overall success of your DTF printing endeavors.

Step-by-Step Guide on Using the DTF Builder

To effectively use the DTF Gangsheet Builder, it is essential to follow a systematic approach. Start by defining your printing requirements, such as the complexity of your designs and the types of materials you are working with. Once you have a clear understanding of your project’s needs, you can prepare your artwork to meet those specifications. This preparation is pivotal, as it sets the tone for how your final prints will turn out.

Next, choosing the right software can greatly enhance your experience with the DTF Gangsheet Builder. Programs such as Adobe Illustrator and CADlink’s Digital Factory provide robust features that are advantageous for professional printing. These tools help to expedite the process of arranging designs on gang sheets, thereby optimizing your workflow even further. By selecting the right software and using a methodical approach, you will ensure that your DTF printing process is both efficient and productive.

Testing Your DTF Prints for Quality Assurance

Testing your DTF prints before the full production run is a critical step that should never be overlooked. Conducting a test print allows you to evaluate the alignment, color accuracy, and overall quality of your designs. Make sure to check the sample output thoroughly for any issues that may compromise the final product, such as color misalignment or lack of vibrancy. This quality assurance process not only saves time and resources but also ensures that your clients receive the best possible product.

In addition to checking alignment and color quality, a robust test print should also include examining the compatibility of the transfer with various garments. Different fabrics behave differently under heat, so understanding how the DTF prints adhere to each type is essential. Testing across a range of materials will give you insight into the longevity of your designs and help to refine your overall printing technique.

Common Mistakes to Avoid in DTF Printing

Even seasoned professionals may encounter common pitfalls when working with DTF printing. One significant mistake is neglecting the preparation of the artwork. Failing to prepare designs at the correct resolution can lead to pixelation or lack of detail, which is particularly detrimental for highly intricate designs. Additionally, not properly setting the printer’s configuration can result in prints that don’t meet quality standards, diminishing the value of the prints you create.

Another common issue is these mistakes often stem from a lack of thorough testing before the complete print run. Skipping the test print stage can result in wasted materials and time, as you may discover issues too late in the process. Always prioritize testing to catch these problems early and ensure that your prints maintain the highest quality possible. By avoiding these mistakes, you can improve both your productivity and the quality of your final products.

The Future of DTF Printing Technologies

As advancements in printing technologies continue to evolve, the future of DTF printing looks promising. Innovations in ink formulations and film technologies are leading to more eco-friendly materials, giving businesses the opportunity to produce sustainable prints that do not compromise quality. With upcoming trends emphasizing environmentally conscious practices, DTF printing may increasingly incorporate recyclable or biodegradable films and inks.

In addition, automation and artificial intelligence are set to play a more significant role in DTF printing processes. Automated software can optimize gang sheet layouts, reducing waste further and increasing production speed. Incorporation of AI-driven solutions will not only streamline workflows but also reduce the manual oversight needed in graphic design and printing processes, making DTF printing more accessible to new users and enhancing productivity across the board.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it improve DTF printing?

A DTF Gangsheet Builder is a specialized software tool that assists in organizing multiple designs on a single sheet for Direct to Film (DTF) printing. It optimizes layout, minimizes ink usage, and enhances workflow efficiency by allowing users to print multiple designs at once, making it ideal for large print runs.

How do I prepare my artwork for the DTF Gangsheet Builder?

To prepare artwork for the DTF Gangsheet Builder, ensure that your designs are at least 300 DPI for high quality, use CMYK color settings for accurate printing colors, and save in compatible file formats like PNG or PDF that maintain transparency without quality loss.

What features should I look for in a DTF Gangsheet Builder software?

When selecting a DTF Gangsheet Builder software, look for features such as automatic layout optimization, compatibility with DTF inks and films, user-friendly interface, and support for various graphic formats. Popular options include CADlink’s Digital Factory, GIMP, and Adobe Illustrator.

What are the steps to configure printer settings for DTF printing using a Gangsheet Builder?

To configure printer settings for DTF printing, select an appropriate printer that supports DTF inks, set the print resolution (typically 1440 DPI), and ensure that the correct type of DTF ink and film is loaded into the printer for optimal results.

How can I ensure the quality of my DTF prints using a Gangsheet Builder?

To ensure quality DTF prints, conduct a test print before the full run to check design alignment and color vibrancy. After printing, allow sufficient cooling time for adhesives to set, and inspect the final products for any defects to maintain high standards.

What are best practices for using a DTF Gangsheet Builder effectively?

Best practices for using a DTF Gangsheet Builder include investing in high-quality films and inks, maintaining printing equipment to avoid issues, and participating in community forums for tips and tutorials. Continuous learning and practice will optimize your DTF printing skills.

| Step Number | Description |

|---|---|

| 1 | Define printing requirements based on design complexity, material type, and order quantity. |

| 2 | Prepare artwork in high-quality resolution and correct color settings using graphic design software. |

| 3 | Choose DTF compatible software for effective gang sheet building. |

| 4 | Load and arrange designs efficiently in the software, ensuring minimal waste. |

| 5 | Configure printer settings for optimal output quality. |

| 6 | Conduct a test print to assess output quality before the final run. |

| 7 | Transfer designs by cutting film and using a heat press according to specifications. |

| 8 | Perform post-production cleanup, allowing cooling and inspecting for defects. |

Summary

DTF Gangsheet Builder is a crucial tool for those involved in Direct to Film printing, allowing users to produce vibrant and durable transfers efficiently. By following a systematic approach that includes defining printing requirements, preparing artwork, selecting the right software, and ensuring proper printer settings, you can optimize your workflow significantly. Each step outlined in this tutorial emphasizes the importance of quality, arrangement, and testing, ensuring your final prints not only meet but exceed professional standards. As you refine your techniques and adapt to new challenges in DTF printing, the DTF Gangsheet Builder will empower you to tackle larger projects with confidence and creativity.