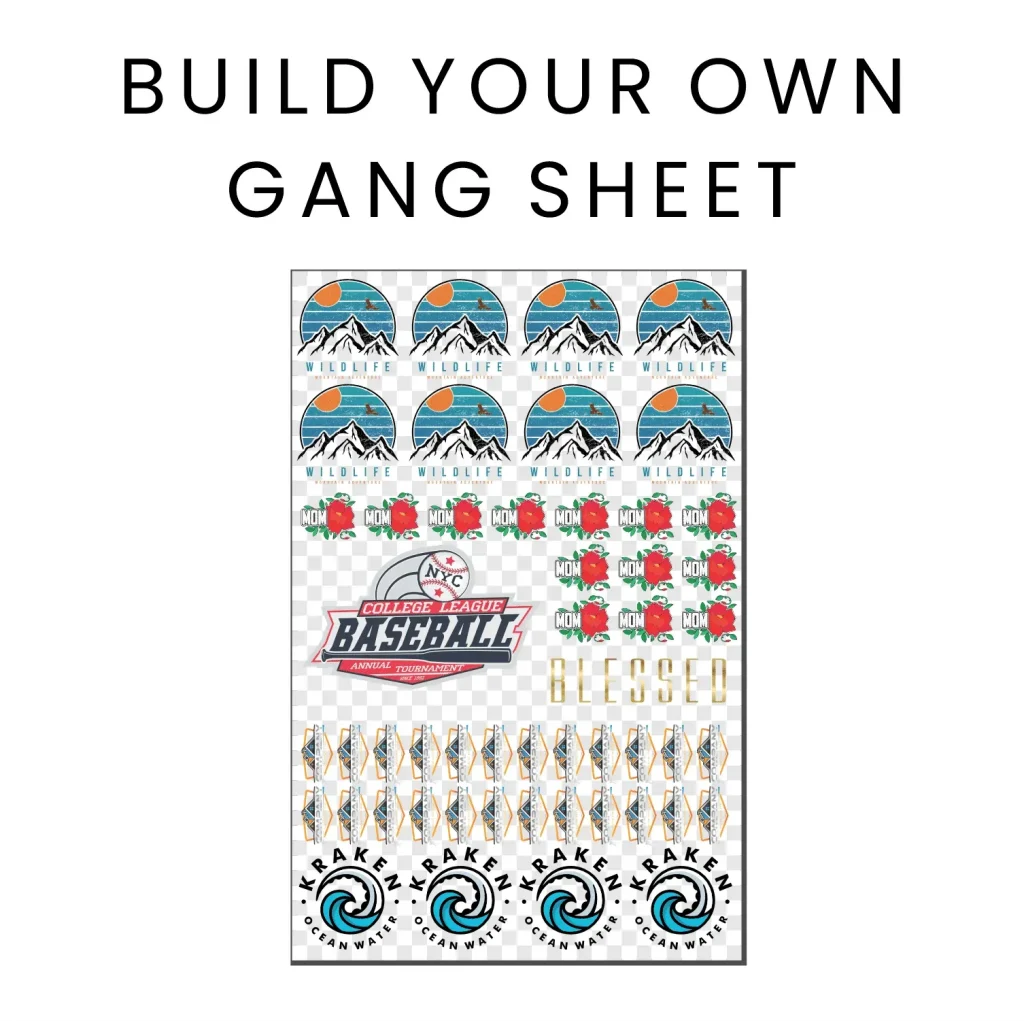

The DTF Gangsheet Builder is a cutting-edge tool that is transforming the landscape of custom apparel printing and promotional item production. With the rapid rise of DTF printing technology, this innovative solution allows businesses to optimize their workflow and enhance print efficiency by consolidating designs into a single film sheet. By utilizing the DTF Gangsheet Builder, printers can significantly reduce material waste and lower operational costs, all while maintaining the high-quality standards that customers expect. As the market for Direct-to-Film printing continues to expand, incorporating advanced features like these is essential for staying competitive. Join the growing number of businesses that are leveraging DTF printer features to revolutionize their printing processes and meet the demands of a dynamic marketplace.

In the realm of printing technologies, the concept of a Gangsheet Builder plays a pivotal role in facilitating custom apparel creation and enhancing promotional material efficiency. This advanced tool is instrumental for businesses looking to streamline their Direct-to-Film (DTF) printing processes, offering a strategic approach to combining multiple designs onto a single transfer film. By employing such innovative options, companies can not only minimize waste and costs but also elevate the quality of their prints, contributing to a more sustainable production model. As printing innovations continue to shape the industry, understanding how to leverage these tools effectively is crucial for maintaining a competitive edge in today’s fast-paced market.

Understanding DTF Printing Technology

DTF printing technology stands out for its unique process of transferring high-quality prints onto various fabrics. The technique involves printing designs onto a film that is then heat-pressed onto garments. This method allows for exquisite color reproduction and intricate detailing, making it a favorite among custom apparel manufacturers. As compared to traditional methods like screen printing, DTF offers greater versatility and customization, enabling businesses to cater to a wider range of client specifications.

The appeal of DTF printing lies in its ability to print on a myriad of fabric types, including cotton, polyester, and blends. This flexibility not only opens doors for creating diverse product lines but also aligns perfectly with the growing demand for personalized promotional items. Furthermore, advancements in DTF printer features have led to sharper and more vibrant outputs, ensuring that designs appear crisp and eye-catching on every piece of apparel.

The Advantages of Using a DTF Gangsheet Builder

Utilizing a DTF Gangsheet Builder is a game-changer for printing businesses, as it revolutionizes how designs are managed and printed. One of the primary benefits is cost efficiency; by allowing multiple designs to be printed simultaneously on one sheet, the overall material costs can significantly decrease. This not only helps businesses save on film but also reduces the amount of waste generated during the printing process.

In addition to saving costs, a gangsheet builder enhances customization capabilities, enabling the production of unique designs tailored to individual client needs. This flexibility is vital in today’s market, where personalized promotional items are highly sought after. Moreover, by streamlining the workflow, a DTF Gangsheet Builder allows for faster production times, making it easier for businesses to meet tight deadlines and fulfill larger orders without sacrificing quality.

Innovative Features of Modern DTF Printers

Modern DTF printers are equipped with a host of innovative features designed to improve printing efficiency and quality. Automatic film feeding systems and high-speed dual printing heads are just a couple of advancements that have made a significant impact on production capabilities. By incorporating these features, manufacturers can produce large volumes of prints in a fraction of the time it would take with older models, thereby increasing overall productivity and output.

The introduction of enhanced ink formulations also plays a crucial role in improving the print quality of DTF technologies. These new inks provide better color stability and adherence to various fabric types, resulting in prints that remain vibrant and intact even after multiple washes. Such advancements ensure that businesses can deliver superior products to their customers, maintaining a competitive edge in the crowded custom apparel market.

Sustainability in DTF Printing Practices

As sustainability becomes a pivotal concern within the printing industry, many DTF printing technologies are adopting eco-friendly practices. The use of water-based inks and recyclable films is gaining traction, reducing the environmental footprint of printing operations. Additionally, adopting these practices not only meets consumer demand for sustainable products but also helps improve a company’s brand image as environmentally conscious.

The shift towards eco-friendly printing solutions highlights a broader trend of integrating sustainability into manufacturing operations. For businesses, investing in green technologies not only appeals to eco-conscious customers but can also lead to cost savings through reduced material waste and improved efficiencies. As the demand for sustainable goods grows, implementing environmentally responsible practices through DTF printing will be crucial for long-term success.

Maximizing Efficiency with a DTF Gangsheet Builder

Integrating a DTF Gangsheet Builder within your printing operations can dramatically enhance production efficiency. To begin with, it’s essential to assess your design needs and production volumes, as this will determine the complexity of the gangsheet layouts you require. Understanding the variety of designs you plan to print will enable you to optimize the arrangement on sheets, ensuring a seamless printing process that minimizes waste.

Choosing the right software to facilitate gangsheet creation is critical. There are numerous options available on the market, so selecting one that integrates well with your existing printing technology and workflow is vital. With proper training for the staff on how to utilize the DTF Gangsheet Builder effectively, you can achieve significant reductions in production errors and delays, leading to a more streamlined and efficient workflow.

Future Trends in DTF Printing and Gangsheet Solutions

The future of DTF printing is poised for remarkable growth, driven by technological advancements and changing consumer demands. As customization continues to dominate the apparel market, innovations in gangsheet solutions will likely evolve to accommodate increasingly complex designs while maintaining ease of use. Future DTF printers may incorporate even more advanced features that facilitate rapid layout adjustments and automated gangsheet optimizations.

Emerging trends also suggest that as e-commerce continues to thrive, the need for quick turnaround times will push the development of speedier printing processes. This means that manufacturers must stay abreast of advancements in DTF printing technology and gangsheet solutions to remain competitive. By continually seeking improvements in efficiency and quality, businesses can leverage these trends to enhance customer satisfaction and drive sales growth in the years to come.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it work?

A DTF Gangsheet Builder is a specialized tool used in Direct-to-Film (DTF) printing technology that optimizes the layout of multiple designs onto a single film sheet. By efficiently arranging designs, it minimizes waste and maximizes material usage, allowing printers to create high-quality custom apparel prints economically. This innovation facilitates a streamlined printing process, significantly improving operational efficiency.

How can a DTF Gangsheet Builder improve my custom apparel printing business?

Utilizing a DTF Gangsheet Builder in your custom apparel printing business can lead to significant cost savings by reducing film usage and minimizing waste. It also enhances workflow efficiency by allowing multiple designs to be printed simultaneously, leading to quicker production times and the ability to offer more customization options to clients.

What are the key benefits of using DTF printing technology with a Gangsheet Builder?

The key benefits of using DTF printing technology combined with a Gangsheet Builder include cost efficiency through reduced film consumption, decreased waste, faster production times, and enhanced print quality. This combination allows businesses to produce vibrant and detailed designs on various fabrics, making it a versatile solution for custom apparel printing.

What innovations are being developed for DTF printers that incorporate Gangsheet Builders?

Recent innovations for DTF printers that incorporate Gangsheet Builders include automatic film feeding systems, enhanced print quality with superior ink formulations, and eco-friendly options like water-based inks and recyclable films. These advancements improve efficiency, reduce environmental impact, and enhance the overall print quality in custom apparel printing.

How does a DTF Gangsheet Builder enhance the sustainability of printing operations?

A DTF Gangsheet Builder enhances sustainability in printing operations by minimizing leftover material and film usage, which leads to reduced waste. Additionally, many DTF printers now use eco-friendly inks and recyclable films, making the entire printing process more environmentally responsible while still delivering high-quality custom designs.

Why is it crucial for printing businesses to adapt to innovations like the DTF Gangsheet Builder?

Adapting to innovations like the DTF Gangsheet Builder is crucial for printing businesses as it allows them to stay competitive in the rapidly evolving custom apparel market. Embracing these advancements improves efficiency, reduces costs, and meets increasing customer demands for quality and customization, thereby enhancing profitability and ensuring long-term success.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A process transferring designs onto film to print on fabrics, offering flexibility and vibrant imagery. |

| Role of a DTF Gangsheet Builder | Optimizes workspace by arranging designs on a single sheet, reducing waste and saving costs. |

| Benefits of Using a DTF Gangsheet Builder | Cost Efficiency, Customization, Streamlined Workflow, Reduced Waste |

| Innovative Technological Advancements | New Equipment, Enhanced Print Quality, Eco-Friendly Options, Market Growth Drivers |

| How to Leverage a DTF Gangsheet Builder | Assess Needs, Choose Right Software, Train Staff, Monitor and Adapt |

Summary

The DTF Gangsheet Builder signifies a monumental leap in the evolution of DTF printing technology. This innovative tool allows businesses to maximize efficiency and minimize costs by arranging multiple designs on a single sheet, leading to reduced material waste. The gangsheet builder not only supports high-quality prints but also adapts to eco-friendly practices, contributing to sustainability in printing. As the demand for customizable products continues to rise, leveraging a DTF Gangsheet Builder can position your operations at the forefront of the industry, ensuring you meet customer needs while promoting a smarter and greener workflow.