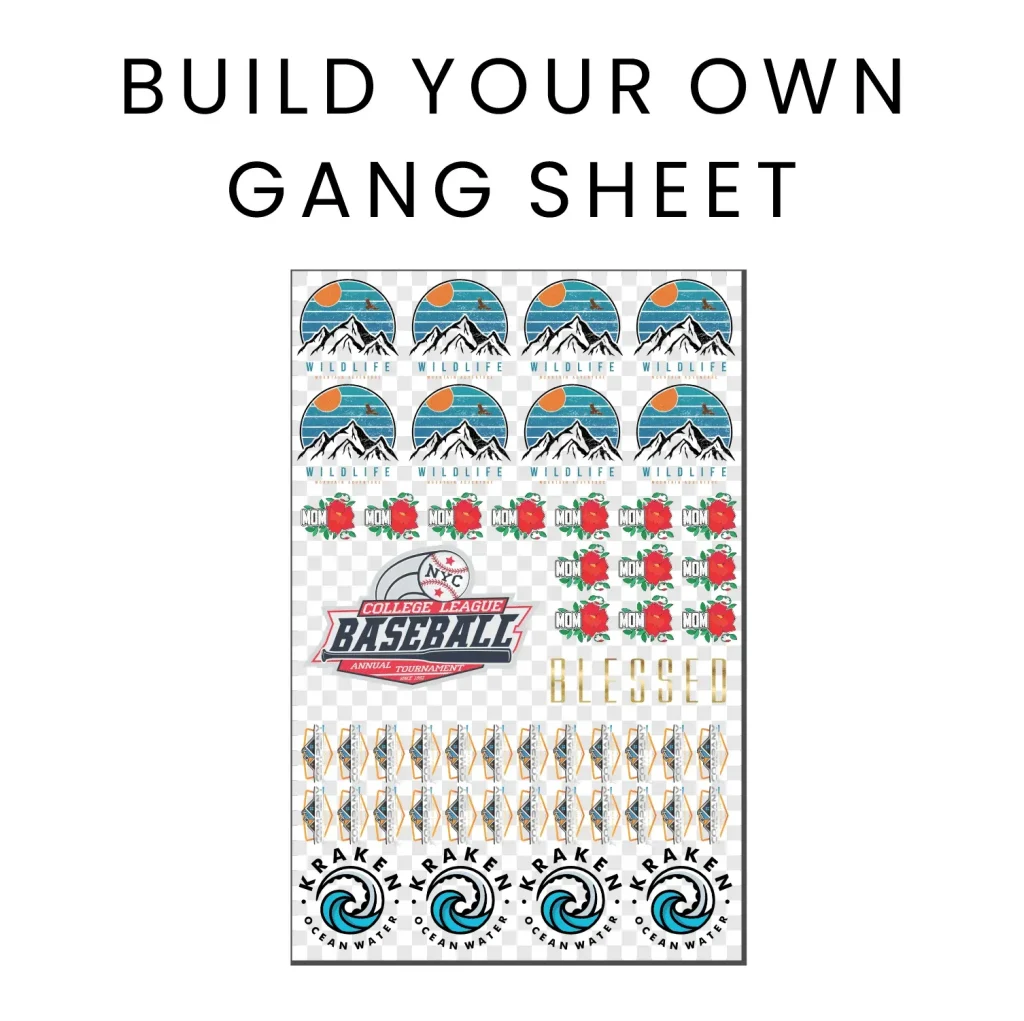

In the rapidly evolving landscape of custom apparel printing, the DTF gangsheet builder has emerged as a game-changing innovation. This advanced method of Direct-to-Film (DTF) printing allows businesses to maximize their creativity while minimizing costs and waste. By leveraging gangsheet printing, users can print multiple designs on a single sheet of DTF transfer films, thus enhancing productivity and efficiency. Whether you’re a small business owner or a hobbyist, the DTF gangsheet builder simplifies the printing process, delivering vibrant and detailed designs on various fabric types. With the growing demand for personalized clothing, mastering this technique can give you a crucial edge in the competitive market of custom apparel printing.

In the realm of custom garment creation, the direct to film gangsheet generator is transforming how individuals and businesses print their designs onto fabrics. Known as DTF printing, this technique utilizes specialized equipment to efficiently transfer exquisite designs onto textiles, making it a favorite among those in the creative industry. The process involves crafting a gangsheet, which allows for several images to be printed simultaneously, optimizing resources and time. As more creators turn to personalized fashion solutions, understanding the functionality of DTF printer technologies and transfer films becomes paramount for success. This guide provides insights and tips for effectively utilizing this innovative approach to garment decoration.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing represents a breakthrough in the world of custom apparel printing. This innovative technology allows designers to create vibrant, high-quality prints on a variety of fabric types, ranging from cotton to polyester and blends. The process begins by printing colorful graphics onto a specially coated film, which is then transferred to the desired textile using a heat press. The flexibility of DTF printing makes it a popular choice for businesses looking to create unique apparel designs.

One of the standout features of DTF printing is its ability to produce intricate designs with remarkable color depth and detail. Unlike traditional screen printing, which can sometimes limit color options and detail resolution, DTF printing opens up a world of possibilities for graphic designers. As a result, apparel brands and custom print shops are increasingly adopting this method to meet the rising demand for personalized and eye-catching clothing.

Exploring DTF Gangsheet Printing Benefits

DTF gangsheet printing is a highly efficient method that enables printers to maximize their production output while minimizing costs. By printing multiple designs on a single DTF film sheet, businesses can effectively lower their material expenses and energy consumption. This not only speeds up the printing process but also allows for greater flexibility in design options, catering to diverse customer preferences.

Additionally, gangsheet printing is particularly advantageous for smaller businesses and entrepreneurs who often face challenges with scalability. By investing in a DTF gangsheet builder, these businesses can efficiently handle larger orders without sacrificing quality. The time-saving benefits and cost reductions make gangsheet printing an attractive option for anyone in the custom apparel market.

Essential Tools for DTF Gangsheet Printing

To embark on your journey in DTF gangsheet printing, you’ll need a few essential tools that facilitate the entire process. First and foremost is the DTF printer, which is specifically designed to handle the requirements of this printing method. Unlike standard printers, DTF printers utilize specialized inks that bond well with the film and fabric, ensuring a vibrant and durable finish.

In addition to the DTF printer, the heat press is crucial for transferring the designs from the film to the apparel effectively. A quality heat press will provide even heat distribution and pressure, which is vital for ensuring that the DTF transfer adheres properly to the fabric. Furthermore, acquiring high-quality DTF transfer films and specialized inks will significantly enhance the quality and longevity of your prints.

The Complete DTF Gangsheet Printing Process

The DTF gangsheet printing process is straightforward and can be broken down into several key stages. It begins with the design creation phase, where graphics are carefully arranged to utilize the gangsheet effectively. Using design software, you can maximize the space on the sheet while ensuring that each design is polished and ready for print.

Once the designs are finalized, they are printed onto the DTF film using the designated printer. After printing, applying a powder adhesive to the moist ink is essential for the transfer process. Finally, the heat press is used to apply intense heat and pressure, ensuring that the ink adheres firmly to the garment. Allowing the item to cool before peeling the film is critical for revealing sharp and colorful designs.

Current Trends in DTF Printing Market

The custom apparel market is experiencing a significant transformation, with DTF printing at the forefront of this change. As e-commerce continues to grow, consumers are increasingly seeking personalized and unique clothing options. DTF gangsheet printing caters to this demand by allowing businesses to create a wide range of products quickly and cost-effectively, hence gaining a competitive edge.

Moreover, the increasing popularity of on-demand printing means that businesses can produce single items or small batches without incurring heavy overhead costs. This flexibility makes DTF printing an appealing choice for entrepreneurs who wish to experiment with different designs and cater to specific market niches. By staying abreast of these trends, businesses can strategically position themselves for success in the evolving landscape of custom apparel.

Expert Tips for Mastering DTF Gangsheet Printing

Achieving successful results in DTF gangsheet printing relies on several key practices. First and foremost, accurate calibration of your DTF printer is critical. Printer settings must be optimized for color representation and print quality; failure to do so could lead to unsatisfactory results that detract from your apparel’s overall aesthetic.

Additionally, selecting high-quality DTF transfer films and specialized inks can dramatically improve the durability and vibrancy of your prints. Regularly testing your settings and materials will help you fine-tune your process and achieve the best results consistently. By keeping abreast of the latest technologies and emerging trends in DTF printing, you’ll be better equipped to navigate the competitive landscape and delight your customers with outstanding designs.

Frequently Asked Questions

What advantages does the DTF gangsheet builder offer in custom apparel printing?

The DTF gangsheet builder provides several advantages in the realm of custom apparel printing, including cost-effectiveness by allowing multiple designs to be printed on a single sheet and reducing wasted materials. It also saves time by minimizing preparation efforts for individual prints, resulting in increased output for larger orders.

How does DTF gangsheet printing work?

DTF gangsheet printing works by first printing multiple designs on a special DTF film using a DTF printer. After printing, a powder adhesive is applied to the wet ink, followed by heat pressing to transfer the designs onto the fabric. This method ensures vibrant and intricate designs on various fabric types.

What equipment is essential for DTF gangsheet building?

To utilize a DTF gangsheet builder effectively, you will need a DTF printer for printing designs, a heat press for transferring prints to fabric, DTF transfer films for the printing process, and specialized inks designed for DTF applications to ensure quality and durability.

Can I use any printer for DTF gangsheet printing?

No, you cannot use any printer for DTF gangsheet printing. A DTF printer is specifically designed to handle the unique inks and films used in the DTF printing process, ensuring optimal print quality and compatibility with DTF transfer films.

What are some tips for achieving high-quality prints with the DTF gangsheet builder?

To achieve high-quality prints with the DTF gangsheet builder, ensure that your printer is properly calibrated for color accuracy, use high-quality DTF transfer films and inks, stay updated on DTF printing advancements, and conduct test prints to optimize settings before full production runs.

Is DTF gangsheet printing suitable for large orders and diverse designs?

Yes, DTF gangsheet printing is ideal for large orders with diverse designs as it allows for multiple graphics to be printed simultaneously on a single sheet. This efficiency helps cater to customer demands while maintaining quality and reducing costs for businesses.

| Key Points | Details |

|---|---|

| Introduction | DTF technology revolutionizes custom apparel printing with cost-effective solutions. |

| What is DTF Printing? | A method using film to transfer vibrant designs onto multiple fabrics. |

| Essence of DTF Gangsheet Printing | Maximizes efficiency and minimizes waste by printing multiple designs. |

| Essential Equipment | DTF printer, heat press, transfer film, specialized inks. |

| Step-by-Step Process | 1. Design creation, 2. Printing, 3. Applying adhesive, 4. Heat transfer, 5. Cooling and peeling. |

| Market Trends | Increasing demand for personalized fashion makes DTF printing popular. |

| Tips for Success | Calibrate printer, select quality materials, stay updated, test prints. |

Summary

DTF gangsheet builder is a game-changer in the world of custom apparel printing, offering a unique blend of efficiency and creativity. This innovative method allows users to maximize productivity while minimizing costs, making it an essential tool for artists, entrepreneurs, and small businesses alike. With the ability to print multiple designs on a single sheet, businesses can cater to various customer preferences without compromising on quality. Understanding the intricacies of DTF gangsheet printing, from equipment requirements to market trends, ensures that you remain competitive in a rapidly evolving landscape, ultimately leading to greater success in your custom apparel ventures.