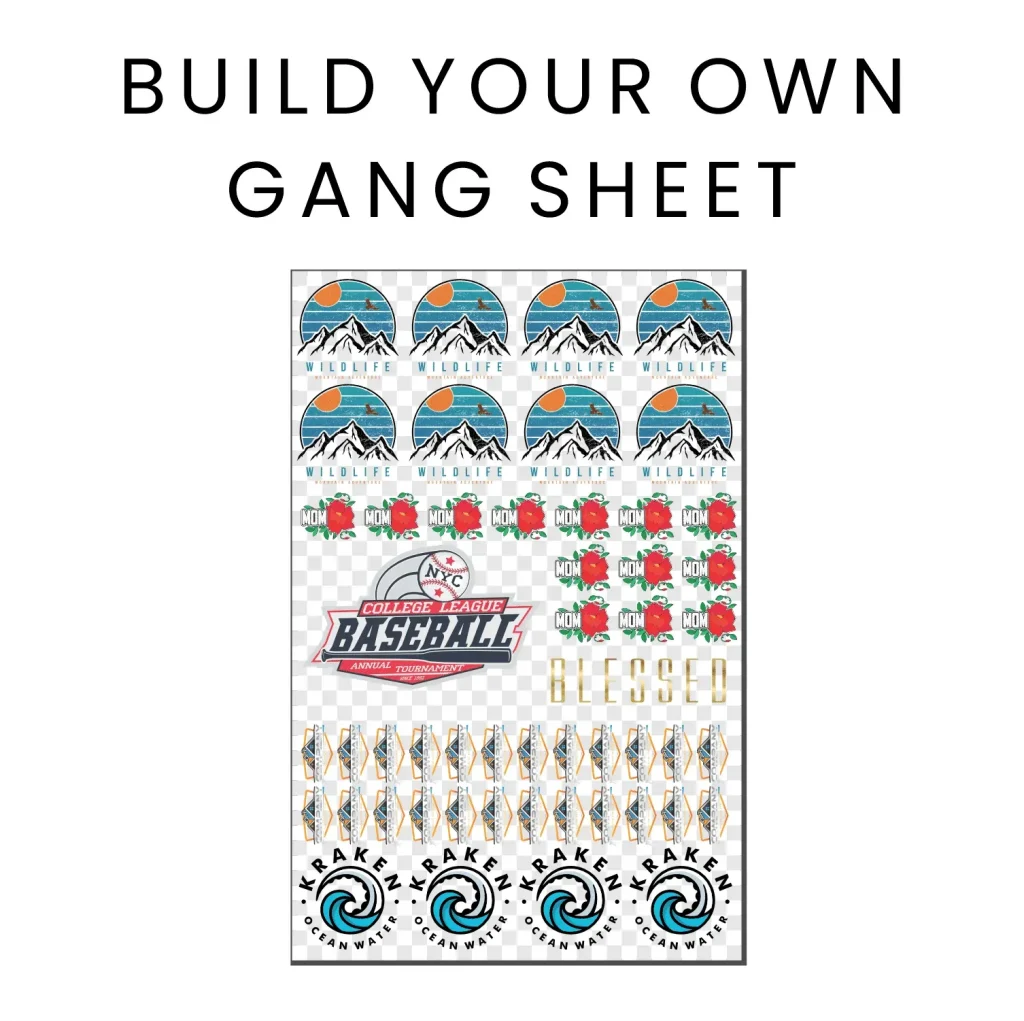

The DTF gangsheet builder is an essential tool for anyone venturing into the world of DTF (Direct to Film) printing, a revolutionary method that transforms the custom apparel industry with its vibrant color reproduction and exceptional print quality. This innovative builder allows users to combine multiple designs onto a single sheet, which streamlines the printing process and significantly reduces material costs. In this tutorial tailored for beginners, we’ll guide you through every step of using this remarkable tool efficiently, ensuring you grasp the fundamentals of the DTF printing process. Moreover, we’ll share valuable DTF printing tips to enhance your printing experience, whether you’re a hobbyist or a budding entrepreneur. Join us as we explore the intricacies of gangsheet printing and unlock your creative potential in custom apparel printing.

When discussing the essential elements of efficient garment decoration, the DTF gangsheet creator comes into play. This innovative software/application enables you to arrange and print several designs simultaneously, maximizing efficiency in custom apparel creation. Understanding the DTF printing method and the concept of gangsheeting is critical for anyone looking to produce vibrant and high-quality prints on textiles. Utilizing the gangsheet format not only saves ink and costs but also simplifies the workflow, introducing a level of convenience that both beginners and seasoned printers will appreciate. Embracing this technology paves the way for creating stunning apparel designs that stand out in a competitive market.

Introduction to DTF Printing and Gangsheet Building

The world of custom apparel has been transformed by Direct to Film (DTF) printing technology, allowing for stunning vibrancy and intricate designs on fabric. At the heart of this innovative process is the DTF gangsheet builder, which enables users to create multiple designs on a single sheet of film. This feature is particularly advantageous for designers and printers who are looking to optimize their production time and materials. With DTF printing, not only are you reducing waste but also gaining the ability to produce high-quality textiles that stand out in today’s competitive market.

Understanding the fundamentals of DTF printing is critical before embarking on the gangsheet building journey. The process itself utilizes water-based inks to transfer designs from a specially coated film onto various fabrics—a technique suited for diverse materials such as cotton, polyester, and their blends. By harnessing the capabilities of a gangsheet, users can maximize both efficiency and cost-savings, an essential factor for both amateur creators and professional businesses alike.

Essential Tools for Effective DTF Gangsheet Creation

To effectively use a DTF gangsheet builder, selection of appropriate design software and tools is paramount. Applications like Adobe Illustrator and CorelDRAW are popular choices, as they provide the necessary features to arrange and manipulate your designs accurately. It’s crucial to set your workspace dimensions thoughtfully, as the size will directly impact how many designs can fit on each gangsheet. Moreover, make sure your printer is equipped with high-quality DTF ink for optimal print results. These preliminary steps lay a strong foundation for a successful custom apparel printing experience.

In addition to software, understanding the specifications of your DTF printer can significantly influence your outcomes. Familiarize yourself with settings specific to gangsheet printing, including media type, print quality, and dimensions. Proper preparation of your workspace and equipment will not only streamline your workflow but also enhance the quality of your final printed garments. A little investment in time and resources upfront can yield impressive results in your custom apparel projects.

Arranging Designs on the DTF Gangsheet

The arrangement of designs on the gangsheet is a critical step that influences not just aesthetics but also functionality. Utilizing a grid layout can help you efficiently place multiple designs without overlap and ensure that each design retains its own space. Adequate spacing is vital, as it prevents potential mishaps during the transfer process, which can lead to wasted materials and time. Planning your design layout meticulously can significantly enhance the usability of your gangsheet.

Taking the time to scale your designs appropriately to fit within the specified dimensions of the gangsheet will maximize the number of prints you can make from a single sheet. Keep in mind that the goal is not only to fit as many designs as possible but also to maintain sufficient space between them for ease of handling during the transfer process. This attention to detail will save you from future headaches, such as alignment issues or accidental mixing of designs when it’s time to apply them to fabric.

Export Settings for Optimal DTF Printing

After completing the arrangement of your designs, the next step involves exporting them in a compatible format for DTF printing. PNG is typically recommended due to its support for transparency, which helps eliminate unwanted backgrounds around your designs. When exporting, ensure that you set the resolution to at least 300 DPI, as high resolution is critical for achieving crisp and vibrant prints on fabric. This ensures that the fine details of your designs are preserved, resulting in high-quality outcomes in your custom apparel projects.

Moreover, adjusting other settings during the export process can provide additional benefits. For instance, consider color profiles that match your printer’s capabilities to avoid unexpected variations in colors after printing. Being mindful of these technical specifications can greatly enhance your DTF printing experience and ensure that your final prints reflect the precision and vibrancy you originally intended.

Printing Your Gangsheet: The Exciting Moment

The printing stage is where all your prior preparations come to fruition—loading your DTF film and ensuring your printer is functioning optimally is vital for success. Use high-quality DTF inks to achieve the brightest colors and best adherence to your fabric. Setting the correct media type and adjusting print settings will also play a crucial role in ensuring a successful transfer during the printing process. This step is not just about pressing the print button; it’s about making sure everything is perfectly calibrated for the best result.

Once you’ve prepared your printer, the excitement heightens as the print begins to emerge. Watch carefully for any discrepancies in color or design, as early detection of issues can save time and materials. Ultimately, ensuring that you’re using the right products and techniques in this phase lays a crucial groundwork for the vibrant and professional-quality prints that DTF printing is known for.

Mastering the Transfer Process for Quality Results

Once the printing is complete, the next significant step is the transfer process. Applying adhesive powder while the printed film is still warm is critical, as this action assures the ink adheres properly to the fabric during the subsequent transfer. Many beginners underestimate this step, but getting it right will ensure that your designs do not wash out or peel over time. Knowing the proper techniques for this step can significantly enhance the longevity and durability of your custom apparel prints.

The curing phase, where you place your printed film into a heat press, requires precision as well. Setting the right temperature and timing is key—typically, a temperature of 320°F for 10-15 seconds achieves optimal adhesive activation. After curing, remember to carefully peel off the film to reveal your design. This moment is often rewarding, showcasing your hard work and dedication to mastering the DTF printing process. Following these methods will solidify your capability of producing high-quality apparel prints.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it work?

The DTF gangsheet builder is a design tool used in DTF printing to arrange multiple designs on a single film sheet for efficient printing. It allows users to maximize ink and material usage, streamlining the custom apparel printing process.

How can I optimize my designs using a DTF gangsheet builder?

To optimize your designs in the DTF gangsheet builder, arrange them in a grid layout with appropriate spacing to prevent overlap, and ensure each design is scaled correctly. This maximizes space and enhances the efficiency of the DTF printing process.

What software is recommended for creating designs with a DTF gangsheet builder?

Popular design software for creating DTF gangsheet designs includes Adobe Illustrator and CorelDRAW. These programs provide essential tools for manipulating designs effectively in preparation for DTF printing.

What are some common DTF printing tips to remember when using a gangsheet builder?

Some useful DTF printing tips while using a gangsheet builder include ensuring high-resolution exports (300 DPI), using PNG formats for transparency, properly applying adhesive powder, and maintaining appropriate curing temperatures during the transfer process.

What materials can I print on using the DTF printing process?

The DTF printing process allows for printing on various textiles, including cotton, polyester, and fabric blends. This versatility makes it ideal for custom apparel projects.

How do I troubleshoot common issues in DTF printing with a gangsheet?

To troubleshoot DTF printing issues, first check printer settings for ink bleeding problems, ensure adhesive powder application is correct for adhesion failures, and adjust curing temperatures if designs are not transferring properly.

| Key Points | Details |

|---|---|

| Introduction to DTF Printing | DTF (Direct to Film) printing enhances custom apparel with vibrant colors and quality. |

| What is a DTF Gangsheet? | A consolidated print sheet to print multiple designs in a single run, saving costs and materials. |

| Key Steps in Building a DTF Gangsheet | |

| 1. Software and Setup | Use design software like Adobe Illustrator or CorelDRAW and set your workspace correctly. |

| 2. Arrange Your Designs | Utilize a grid layout and ensure proper spacing between designs. |

| 3. Export Settings | Export designs in PNG format at 300 DPI for quality results. |

| 4. Printing Process | Ensure printer is set up properly with high-quality DTF inks and the right media type. |

| 5. Transfer Process | Apply adhesive powder and cure the print in a heat press before peeling. |

| Troubleshooting Tips | Common issues include ink bleeding and adhesion problems. |

| Conclusion | Mastering DTF gangsheet builder leads to high-quality custom printing. |

Summary

The DTF gangsheet builder is a crucial tool for anyone interested in custom apparel printing, allowing for the efficient arrangement and printing of multiple designs. By understanding DTF printing fundamentals and following the outlined steps, beginners can create stunning designs that stand out in the market. Commitment to mastering these techniques will not only enhance your printing capabilities but also open up new avenues for creative expression in the thriving industry of custom apparel.