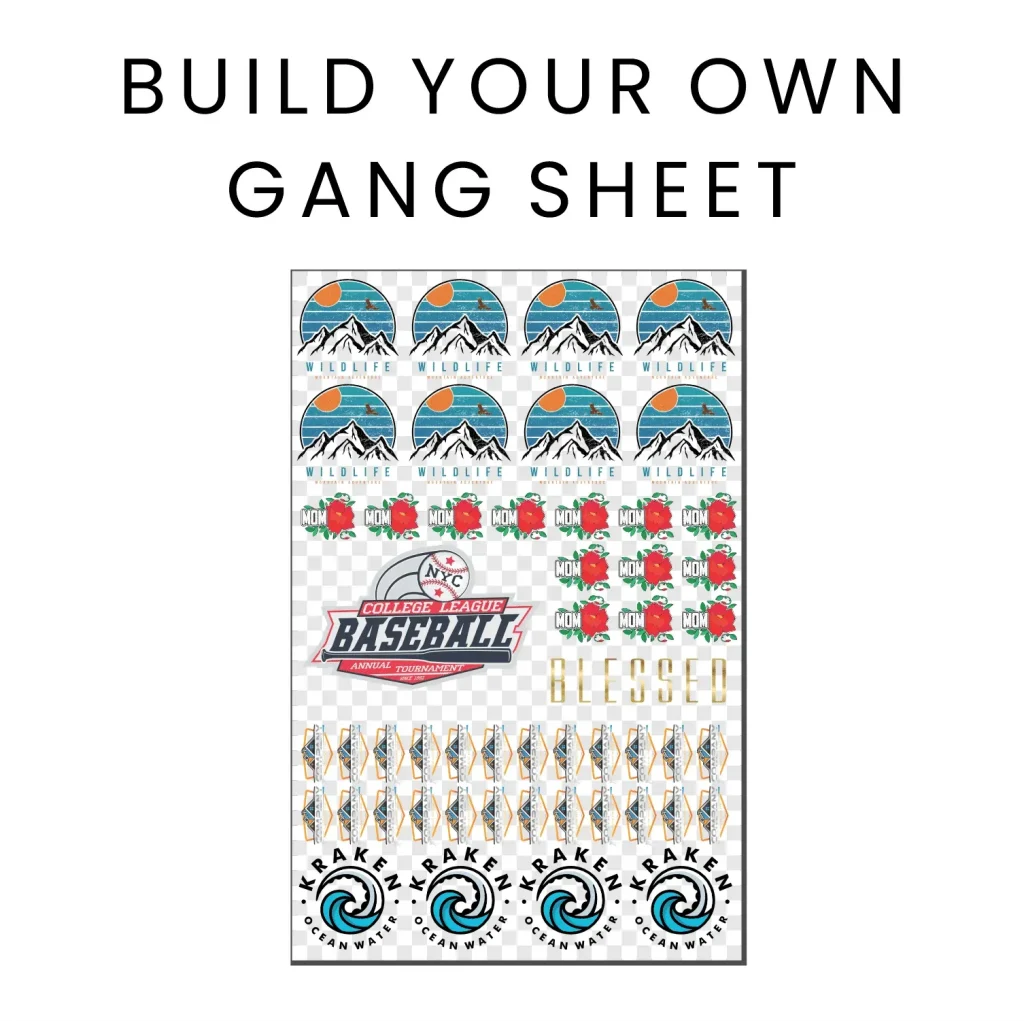

In the ever-evolving landscape of custom transfer printing, the DTF Gangsheet Builder emerges as a game-changer for designers and crafters alike. This innovative software streamlines the DTF printing process by allowing users to compile multiple designs onto a single sheet, making operations more efficient and cost-effective. With the rise of advanced printing techniques, the DTF Gangsheet Builder not only maximizes design potential but also promotes sustainability through reduced material waste. By leveraging DTF printing tips, creators can achieve vibrant, high-quality prints that truly stand out. In this guide, we’ll delve into design optimization strategies using the DTF Gangsheet Builder that can elevate your crafting projects to a new level.

When it comes to enhancing custom design projects, tools like the DTF Gangsheet Builder play a vital role in the creative process. This powerful application simplifies the gang sheet design method, allowing users to efficiently print several designs simultaneously. Additionally, optimizing your printing techniques can lead to better resource management and improved output quality, making it an essential step for anyone invested in custom transfer techniques. By mastering the intricacies of DTF printing, from layout optimization to color accuracy, you can unlock new possibilities in your designs. Embracing these concepts will not only help in shortening production times but will also empower creators to explore their artistic visions freely.

Understanding DTF Printing Technology

DTF printing technology has revolutionized the way creators approach custom designs. By providing a method that allows for vibrant and detailed prints directly onto fabrics, it has swiftly become a favorite among crafters. The introduction of DTF Gangsheet Builder specifically enhances this technology by enabling the creation of gang sheets. These sheets allow multiple designs to be printed simultaneously, drastically reducing material waste and offering a more efficient production process for small businesses and hobbyists alike.

Moreover, the flexibility offered by DTF technology supports a wide range of applications, from apparel to home decor. Creators can explore intricate designs that were once challenging or cost-prohibitive with traditional printing methods. This makes DTF an attractive option for those who wish to expand their product offerings, ensuring that the final outcome reflects the high quality expected by consumers.

Benefits of Using the DTF Gangsheet Builder

The DTF Gangsheet Builder stands out because it allows users to fully utilize the capabilities of DTF printing. One primary advantage is the economic efficiency it offers. By arranging multiple designs on a single sheet, creators can produce a higher volume of prints without the accompanying waste often seen in one-off print jobs. This economic benefit is particularly crucial for small-scale operations and startups, allowing them to maintain profitability as they grow.

Additionally, the Gangsheet Builder empowers users to engage in design optimization. By experimenting with layouts and design sizes, creators can maximize not only material usage but also the overall aesthetic appeal of their products. This optimization can lead to an increase in customer satisfaction and repeat business, making the tool invaluable in the competitive market of custom printing.

Tips for Effective Gang Sheet Design

When designing gang sheets, a few key tips can significantly impact the outcome. Firstly, consider the optimal arrangement of your graphics. Grouping designs that share similar themes or colors can enhance the overall flow of the finished product. Furthermore, ensuring that designs do not overlap or interfere with one another will conserve resources and maintain quality. The DTF Gangsheet Builder facilitates this type of design planning with user-friendly software that streamlines the process.

Secondly, adjust design sizes appropriately based on the products you intend to print. It’s essential to benchmark sizes against the final application to avoid underwhelming results. By utilizing scalable vector graphics, users can maintain quality while adapting dimensions. This attention to detail enhances the efficacy of the printing technique, ensuring that every design emerges bright and clear, regardless of the fabric or surface used.

Color Management in DTF Printing

Color management is a crucial aspect when it comes to DTF printing, as it can determine the final quality of your output. Implementing accurate color profiles during the design process ensures that the colors displayed on-screen are replicated accurately in the print. Such precision is vital in maintaining customer satisfaction and brand integrity. With DTF printing’s distinct color outputs, advancements in color management technology help to bridge potential gaps in color accuracy.

Additionally, once you complete your designs, it is beneficial to preview them against your chosen medium. This allows for critical adjustments before the final printing. An investment in color calibration tools can further refine this process, ensuring that each print arrives with the intended vibrancy and detail.

Importance of Pre-treatment Techniques

Pre-treatment is an often-overlooked aspect of the DTF printing process. It enhances the bond between the ink and the fabric, ultimately contributing to the durability and vibrancy of the print. Failing to pre-treat may result in colors that fade or bleed over time, disappointing creators and customers alike. By experimenting with various pre-treatment techniques, users can significantly improve the longevity and quality of their designs.

Different fabrics may require specific pre-treatment solutions to achieve optimal results. For dark or unique textures, specially formulated agents might be necessary to ensure vibrant, lasting prints. Therefore, researching and testing different pre-treatment methods is essential to refine your process and consistently produce outstanding designs.

The Role of Test Prints in Production

Conducting test prints is an essential step in the production process, particularly for creators who want to safeguard their investment in materials and time. Test prints help identify potential flaws, such as clarity, color fidelity, and material compatibility, that can arise before committing to a full production run. This practice not only saves resources but also enhances the quality assurance of the products offered to customers.

Moreover, conducting test runs allows for adjustments in real-time, permitting creators to perfect their designs. By integrating feedback from test prints into the final output, users can address issues effectively and refine their methods, thus ensuring a seamless transition from concept to production. Ultimately, this proactive approach to testing can lead to a more efficient workflow and improved customer satisfaction.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a software tool specifically designed for crafters using DTF (Direct to Film) printing technology. It allows users to create gang sheets, which consist of multiple designs printed simultaneously. This method not only minimizes material waste but also streamlines the custom transfer printing process, enhancing efficiency for creators.

How can I optimize my designs using the DTF Gangsheet Builder?

To optimize your designs with the DTF Gangsheet Builder, focus on arranging multiple designs on a single sheet and adjusting their sizes appropriately for the intended substrate. This not only maximizes the number of impressions per print run but also effectively reduces production costs, making your custom printing projects more efficient.

What are some essential DTF printing tips for beginners?

For beginners using DTF printing, consider implementing color management techniques to ensure screen-to-print color accuracy, conducting test prints to identify design issues, and exploring various pre-treatment options for fabrics. These DTF printing tips can significantly improve the quality and durability of your custom transfers.

What are the benefits of using gang sheet design in my projects?

Using gang sheet design with the DTF Gangsheet Builder allows you to consolidate multiple designs on one sheet, leading to reduced material waste and faster production times. This method is especially valuable for small businesses and crafters looking to maximize efficiency while creating high-quality custom prints.

How does color management play a role in DTF Gangsheet Builder projects?

Color management is crucial when using the DTF Gangsheet Builder, as DTF printing has unique color outputs. Implementing accurate color profiles ensures that the colors displayed on your screen match the final print. Adjusting colors during the design phase and previewing them can help you achieve the best results in your custom transfer printing.

What pre-treatment techniques should I consider for DTF printing on fabrics?

Pre-treatment techniques are vital for ensuring vibrant colors and proper adhesion when using DTF printing on fabrics. Experimenting with different pre-treating methods can enhance print quality, particularly for dark fabrics or intricate designs. Proper pre-treatment is essential for achieving long-lasting and striking results in your custom transfers.

| Key Aspect | Details |

|---|---|

| DTF Printing Technology | Allows vibrant designs printed directly on fabrics and surfaces. |

| DTF Gangsheet Builder | A software tool for creating gang sheets, reducing waste and streamlining printing. |

| Benefits of DTF Printing | Improved design creation, faster production times, design flexibility. |

| Maximizing Designs | Strategies include optimizing layouts, adjusting sizes, color management, pre-treatment, and test prints. |

Summary

The DTF Gangsheet Builder is a revolutionary tool that significantly enhances the custom design process for crafters and small businesses. By employing strategies like optimizing layouts, managing colors accurately, adjusting design sizes, utilizing effective pre-treatment techniques, and conducting thorough test prints, users can ensure that each print is not only visually stunning but also produced efficiently. The advancements in DTF printing technology empower creators to explore new possibilities in their craft, driving innovation and creativity across various materials. Embracing these techniques will transform your approach to custom printing, elevating your projects to new heights.