The advantages of DTF printing are revolutionizing the custom apparel market by providing businesses with high-quality, versatile, and cost-effective printing solutions. Direct-to-Film (DTF) printing is rapidly emerging as a preferred choice due to its ability to deliver vibrant colors and intricate designs on a wide range of fabrics. This innovative printing technique also aligns with the growing demand for eco-friendly printing options, utilizing water-based inks that minimize environmental impact. Additionally, DTF printing offers economic benefits, especially for small production runs, enabling businesses to produce personalized items without incurring hefty upfront costs. As more companies recognize these DTF printing benefits, they are increasingly adopting this technology to meet the diverse needs of their customers.

Exploring the perks of Direct-to-Film printing sheds light on a novel technique that is reshaping the landscape of apparel decoration. This method, involving the transfer of printed designs from film onto textiles, stands out for its quality and efficiency, making it an ideal option for businesses seeking innovative approaches to custom apparel printing. With its vibrant graphic output and adaptability across various materials, this printing style not only caters to growing consumer preferences but also embraces sustainable practices by utilizing eco-friendly inks. Moreover, the economic advantages associated with this method, especially for small orders, position it as a smart choice for manufacturers. By harnessing DTF technology, businesses can effectively meet market demands while keeping costs in check.

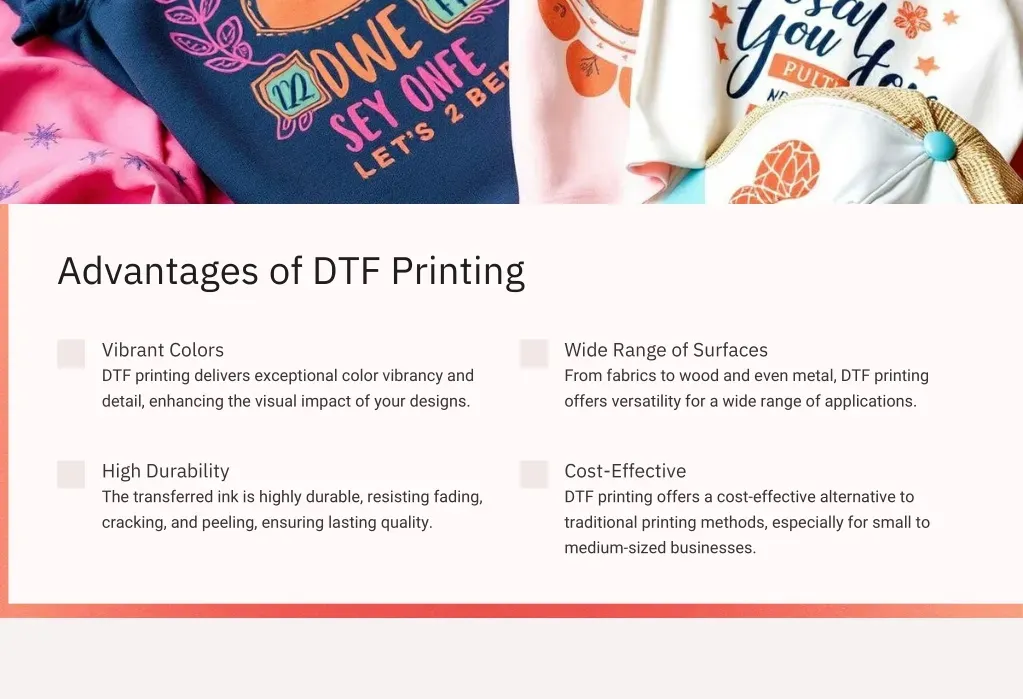

Quality and Versatility in DTF Printing

Direct-to-Film (DTF) printing sets itself apart with its exceptional quality and versatility compared to other printing methods. This innovative technology allows for high-resolution prints with vibrant colors that truly pop on anything from cotton to polyester. In contrast to traditional printing techniques, such as screen printing, which can limit the range of customizable options, DTF printing caters to a diverse array of textiles. This flexibility not only broadens the scope for businesses offering custom apparel printing but also enhances the potential for creative design offerings.

Moreover, the versatility of DTF printing enables businesses to cater to various markets, from fashion to promotional items. The technology supports intricate designs and patterns that resonate well with consumers seeking unique personalizations. Additionally, this adaptability makes DTF a preferred choice for small to medium-sized businesses, as it allows them to experiment with multiple fabric types without investing excessively in different printing systems. This characteristic fosters innovation and creativity in the custom apparel sector, appealing to a wider array of customer preferences.

Cost-Effective Printing Solutions

One of the standout advantages of DTF printing is its cost-effectiveness, particularly for businesses looking to produce small runs. Traditional printing methods often involve significant setup costs, which can render small orders financially impractical. DTF printing eliminates many of these overheads, enabling companies to fulfill smaller orders without compromising on quality or incurring hefty expenses. This feature is particularly beneficial for custom apparel businesses that thrive on personalized items, allowing them to offer unique products without significant investment in traditional equipment.

The cost-saving aspect of DTF printing extends beyond the initial setup. Its efficient use of materials means that waste is minimized – a crucial factor for both budgeting and sustainability goals. By adopting DTF technology, businesses can keep their production lines lean, cutting down expenses while still providing high-quality prints. This financial efficiency allows companies to remain competitive in a tough market, ensuring they can offer compelling pricing options while maintaining healthy margins.

Eco-Friendly Printing Practices

In today’s environmentally conscious market, businesses are increasingly seeking eco-friendly printing solutions. DTF printing uses water-based inks, which generate fewer harmful emissions compared to solvent-based inks found in some traditional printing methods. By opting for DTF technology, businesses not only contribute to reducing their carbon footprint but also appeal to a growing demographic of consumers who prioritize sustainability. This eco-friendly aspect of DTF printing can be a strong selling point, helping brands differentiate themselves in a crowded market.

Additionally, adopting DTF printing aligns with broader corporate social responsibility strategies. By reducing harmful waste and utilizing sustainable materials, companies can enhance their brand image and attract environmentally-aware customers. Furthermore, as regulatory pressures around environmental practices increase, transitioning to eco-friendly printing methods becomes a strategic move that not only supports customer values but also positions companies favorably within an evolving market.

Speed and Efficiency of DTF Printing

Speed is a critical factor in the fast-paced landscape of custom apparel printing, and DTF technology shines in this regard. With significantly reduced setup times and faster printing processes, DTF printing enables businesses to meet immediate demands and fulfill customer orders more rapidly. This efficiency not only satisfies consumer expectations but also allows businesses to adapt quickly to seasonal trends and sudden spikes in demand without compromising quality.

Moreover, the ability to produce high-quality prints at a quicker pace gives companies leveraging DTF printing a competitive edge. This speed ensures quicker turnaround times on custom orders, making it easier for businesses to attract and retain clients. As clients increasingly seek swift delivery times alongside quality, the efficiency offered by DTF printing solidifies its status as a premier choice in the apparel and textile printing industry.

Technological Innovations in DTF Printing

As DTF printing technology continues to evolve, recent innovations have greatly enhanced its capabilities. Updates in printer resolution and ink formulations lead to improved color vibrancy and detail, allowing businesses to produce stunning visual results. These advancements not only bolster the output quality but also democratize access to high-performance printing capabilities for smaller print shops and businesses. The increasing affordability of DTF printing technology represents a critical shift for the industry.

Furthermore, equipment manufacturers are investing heavily in research and development to innovate further, tapping into new printing techniques that enhance efficiency and usability. This trend towards continuous improvement means that DTF technology is becoming more adaptable and user-friendly, encouraging wider adoption across various sectors. With these ongoing innovations, businesses that integrate DTF technology are better positioned to meet changing market demands and expand their service offerings.

Recent Developments in DTF Printing Applications

The growing interest in DTF printing over recent years is reflected in its rising applications across various industries. From retail businesses aiming to provide unique custom apparel to graphic print shops seeking efficient solutions, DTF technology has proven instrumental in accommodating diverse printing needs. One notable trend is the increasing demand for personalized and customized products, which DTF printing caters to perfectly due to its flexibility and high-quality output.

Additionally, as advancements in DTF technology continue to gain traction, equipment manufacturers are facilitating broader accessibility for small to medium-sized businesses. This newfound capability enables more enterprises to incorporate DTF printing into their operations, allowing them to stay relevant in a landscape increasingly defined by consumer personalization. The rise of DTF applications strengthens its position as a significant player in the future of textile printing, promising a continued transformation in how businesses approach custom apparel production.

Frequently Asked Questions

What are the main advantages of DTF printing in custom apparel printing?

DTF printing offers several advantages in custom apparel printing, including high-quality output, vibrant colors, and versatility to print on various fabrics. This technology allows businesses to cater to diverse customer needs while maintaining exceptional print quality.

How does DTF printing provide cost-effective printing solutions for small orders?

DTF printing is particularly cost-effective for small runs because it requires minimal setup time compared to traditional screen printing. This efficiency allows for quick production and reduced waste, making it economical for businesses that need personalized items without significant upfront costs.

Is DTF printing an eco-friendly printing option?

Yes, DTF printing is considered eco-friendly as it utilizes water-based inks, which produce fewer harmful emissions compared to solvent-based inks. This makes it an attractive choice for brands looking to enhance their sustainability efforts and appeal to environmentally conscious consumers.

What benefits does DTF printing offer in terms of speed and efficiency?

DTF printing provides rapid turnaround times, allowing businesses to meet tight deadlines effectively. With faster setup times and quicker printing processes compared to traditional methods, DTF technology helps maintain high levels of customer satisfaction by ensuring timely order fulfillment.

How has DTF printing technology evolved to enhance its capabilities?

Recent innovations in DTF printing technology have improved print resolution, color vibrancy, and format handling. These advancements make DTF printing more accessible and efficient for small businesses, enabling them to produce high-quality prints that meet the demands of a competitive market.

Why should businesses consider adopting DTF printing for their production needs?

Businesses should consider adopting DTF printing due to its numerous advantages such as exceptional quality, versatility across fabrics, cost-effectiveness for small runs, and eco-friendliness. As a modern solution, DTF printing positions businesses favorably in the evolving textile printing industry.

| Advantage | Description |

|---|---|

| Quality and Versatility | Produces high-quality prints with vibrant colors and sharp details, compatible with various fabric types. |

| Cost-Effective for Small Runs | Reduces costs for small production runs by minimizing setup time and waste. |

| Eco-Friendly Options | Uses water-based inks that are less harmful to the environment, appealing to eco-conscious consumers. |

| Speed and Efficiency | Offers rapid turnaround times, allowing businesses to meet tight deadlines effectively. |

| Innovations and Technology | Continual advancements in DTF technology improve print quality and usability for small businesses. |

Summary

The advantages of DTF printing are numerous and significant, making it a compelling choice for the custom apparel industry. With its ability to produce high-quality and versatile prints at a lower cost for small runs, DTF printing enables businesses to meet diverse customer needs efficiently. Additionally, its eco-friendly nature aligns with the increasing demand for sustainable practices. As advancements in technology continue to refine this printing method, DTF printing stands to enhance operational speed and efficiency. Ultimately, leveraging the advantages of DTF printing can differentiate your business in a competitive market, fostering greater customer satisfaction and engagement.