In the dynamic realm of textile printing, the DTF Gangsheet Builder has emerged as a transformative tool for print professionals aiming to optimize their production processes. This innovative method facilitates the direct-to-film printing technique, allowing users to efficiently create gang sheets that maximize material use while minimizing waste. With the increasing popularity of DTF printing, mastering the DTF Gangsheet Builder can unlock new possibilities for vibrant designs and rapid production. By utilizing print optimization techniques, manufacturers can fulfill larger orders without sacrificing quality, ensuring each print job meets high standards. In this article, we’ll delve into essential tips and tricks that will empower you to harness the full potential of the DTF Gangsheet Builder for exceptional print results.

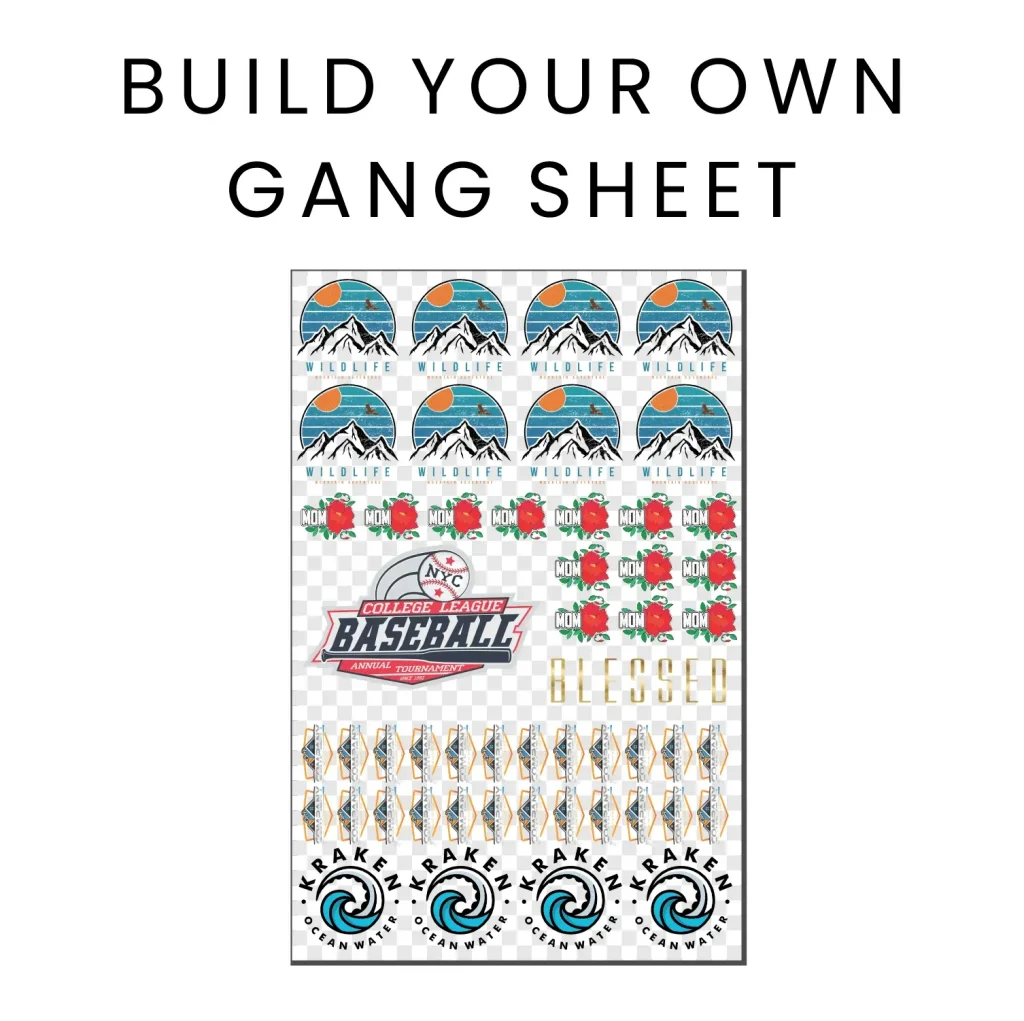

In the fast-evolving field of `direct-to-film` technology, the concept of the gang sheet presents an effective strategy for managing print jobs. This process, often referred to as “gang sheet printing,” allows for multiple designs to be printed on a single film sheet, making it an economical choice for small businesses and large operations alike. Utilizing gang sheets not only reduces material waste but also enhances the overall efficiency of the printing process. As cotton, polyester, and other fabrics increasingly dominate the market, mastering textile printing tips related to gang sheet production becomes crucial for maintaining competitive edge. In this guide, we’ll explore various facets of utilizing the gang sheet builder to elevate your printing business.

Maximizing Efficiency with the DTF Gangsheet Builder

The DTF Gangsheet Builder serves as a game-changer for businesses seeking to optimize their printing processes. By utilizing a gang sheet, you can print multiple designs in one go, significantly reducing wasted material and maximizing the efficiency of your operations. This method not only cuts down on ink and film usage but also minimizes the time and labor required for setup and print runs. As a result, businesses are able to boost their productivity, fulfilling larger orders more swiftly and with fewer resources.

Utilizing gang sheets can transform the way you handle orders. As orders grow larger, the ability to print multiple designs simultaneously is invaluable. When you manage to fit various designs into a single DTF gangsheet, you can greatly reduce the complexity of your workflow. Moreover, this technique allows for easier organization of print jobs, ensuring that production runs smoothly, thus enhancing overall turnaround times and helping to meet client demands swiftly.

Understanding DTF Printing Techniques

DTF printing, or Direct-to-Film printing, has gained popularity due to its ability to transfer vibrant and durable prints onto fabrics. This process begins with printing designs onto a special film, followed by a heat transfer to the garment, resulting in high-quality and long-lasting images. The versatility of the DTF method allows it to cater to various types of textiles, making it an excellent choice for businesses in the custom apparel and promotional goods market.

Moreover, DTF printing stands out because it maintains great fidelity to the original artwork. Unlike other textile printing techniques, DTF allows for intricate details and a wide color gamut, which is perfect for those looking to produce high-quality merchandise. By mastering DTF printing techniques, including efficient use of gang sheets, printers can offer remarkable products that stand out and meet the stringent demands of today’s customers.

Key Benefits of Gang Sheet Printing

Gang sheet printing offers multiple benefits that can significantly impact your bottom line. One of the most significant advantages is cost savings. By printing several designs on one sheet, you reduce the number of prints needed, leading to lower media and ink costs. This efficiency is especially advantageous for small to medium-sized businesses that may have budget constraints but still wish to deliver high-quality prints to their customers.

In addition to financial savings, gang sheet printing helps in reducing the environmental impact of your operations. Less material waste means a smaller carbon footprint, and this aspect cannot be overlooked in today’s eco-conscious market. By adopting DTF gangsheet builders, businesses not only enhance their productivity but also align themselves with sustainable practices that appeal to environmentally aware customers.

Essential Tips for Effective Design Layout

Creating an effective design layout is crucial when building gang sheets to ensure maximum usage of your printable area. Start by arranging your designs logically, without leaving unnecessary gaps that would waste valuable film space. Utilizing software tools designed for DTF printing can streamline this process, allowing you to visualize and adjust layouts effectively before printing.

Another important aspect of design layout is maintaining clear spacing and alignment between each design. It is recommended to leave a quarter-inch gap to allow for cutting and prevent any misalignment errors that could compromise your quality. Mastering this part of the process can make a substantial difference in the final result of your prints, ensuring that your customers receive flawless products.

Testing Your Prints for Quality Assurance

In the realm of DTF printing, quality assurance is paramount. Conducting test prints before a major production run allows you to review color accuracy, alignment, and overall appearance. This step is not just a precaution; it is an essential part of the printing workflow that can save businesses from costly errors down the line. By identifying potential issues during the test print phase, you can make adjustments and verify that your final output meets desired specifications.

Moreover, keeping a record of your test prints can also serve as a benchmark for future orders. This practice provides valuable insights into what settings yield the best results in terms of vibrancy and clarity. By sharing these findings within your team, you can cultivate a culture of continuous improvement, enhancing your overall production quality with each print job.

Staying Innovative in DTF Printing Trends

The DTF printing industry is evolving rapidly, with new technologies, materials, and techniques constantly emerging. Staying updated with the latest industry trends is crucial for any business looking to maintain a competitive edge. Engaging with resources, such as industry publications or online communities, can provide you with insights into the newest advancements in DTF technology, from new inks to cutting-edge print optimization techniques.

Additionally, exploring current market trends can also inspire fresh creative designs and novel applications of DTF printing beyond traditional uses. By embracing innovation and adapting to these changes, businesses can attract new customers and retain existing ones by offering the latest in print quality and customization options. Continuing education and adaptation will ensure that your services remain relevant in an ever-changing landscape.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work in DTF printing?

The DTF Gangsheet Builder is a tool used in DTF (Direct-to-Film) printing that allows multiple designs to be printed on a single film sheet simultaneously. By utilizing this method, users can optimize material usage, reduce costs, and increase efficiency while maintaining high-quality prints.

How can I optimize my designs using the DTF Gangsheet Builder?

To optimize your designs with the DTF Gangsheet Builder, ensure you prepare high-resolution images, efficiently arrange them to maximize space, and maintain proper spacing between designs. These practices will enhance your print jobs and minimize waste.

What are some print optimization techniques for using a DTF Gangsheet Builder?

Effective print optimization techniques when using a DTF Gangsheet Builder include utilizing design software for layout, preparing images in the correct color format, conducting test prints for quality assurance, and arranging your designs to reduce gaps within the print area.

Can the DTF Gangsheet Builder improve productivity in textile printing?

Yes, utilizing the DTF Gangsheet Builder can significantly enhance productivity in textile printing. By allowing multiple prints to be processed at once, businesses can streamline their workflow, reduce downtime, and complete larger orders more efficiently.

What are some common textile printing tips for using the DTF Gangsheet Builder?

Common textile printing tips for the DTF Gangsheet Builder include ensuring high image resolution, planning layout effectively to maximize printable space, and regularly updating skills and knowledge about the latest DTF printing technologies and trends.

What software tools are recommended for creating effective DTF Gang Sheets?

Recommended software tools for creating effective DTF Gang Sheets include Adobe Illustrator and specialized print design software. These applications provide features designed for DTF printing, such as templates and layout precision, which help streamline the printing process.

| Key Aspect | Description |

|---|---|

| DTF Technology | A printing method where designs are printed onto a film and transferred to fabric, offering high durability and vibrant colors. |

| Benefits of Gang Sheets | Minimizes waste, reduces costs, and enhances productivity by allowing multiple designs to be printed on a single sheet. |

| Image Preparation | Ensure images are high resolution and in the correct color format for optimal print quality. |

| Design Layout | Plan your layout efficiently to maximize space and minimize waste, keeping gaps to a minimum. |

| Spacing and Alignment | Maintain at least a quarter-inch gap between designs to avoid misalignment during cutting. |

| Software Tools | Use design software like Adobe Illustrator to streamline gang sheet creation. |

| Test Prints | Conduct test prints to check for color quality and alignment before final production. |

| Staying Updated | Keep informed on industry trends through magazines and resources for ongoing learning. |

Summary

The DTF Gangsheet Builder is essential for anyone looking to achieve outstanding print results while optimizing their costs. By employing efficient techniques such as proper image preparation, thoughtful design layout, and practical use of software tools, you can significantly enhance your print quality. Additionally, staying updated with the latest DTF trends ensures your printing practices remain innovative and effective. Embracing these strategies will not only reduce waste but also contribute positively to customer satisfaction and business growth. Harness the power of the DTF Gangsheet Builder today to take your textile printing endeavors to the next level!