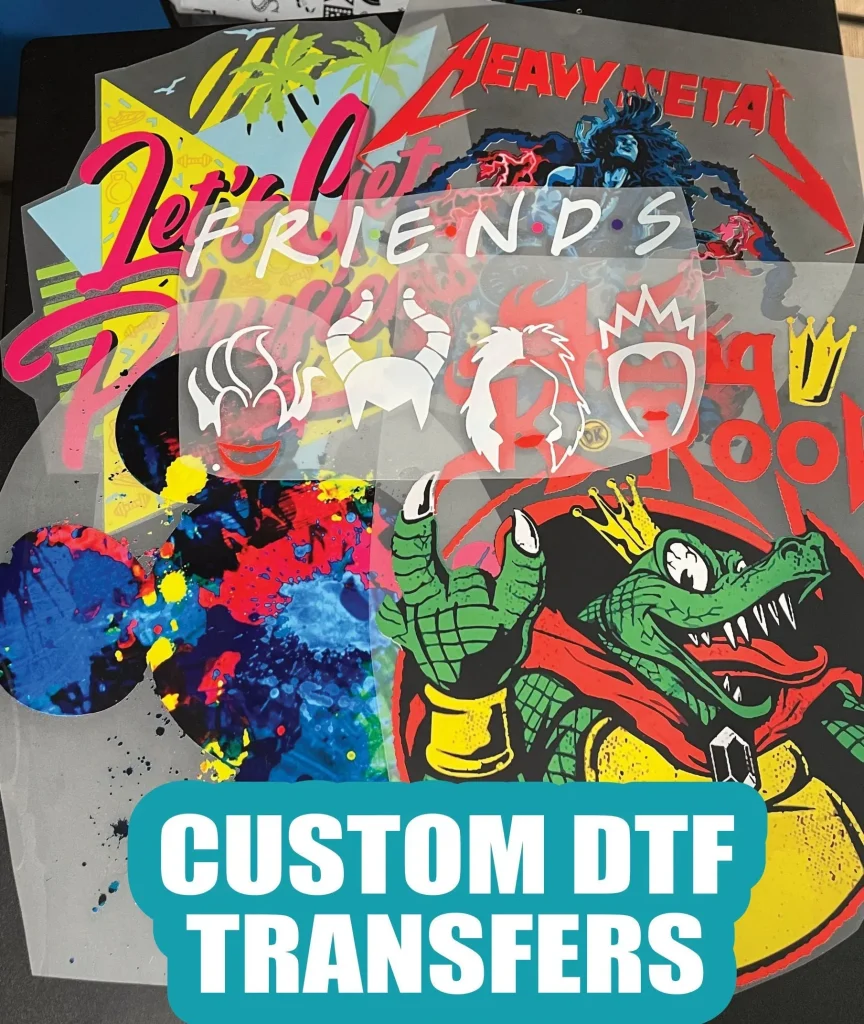

In recent years, DTF transfers, or Direct to Film transfers, have garnered immense popularity as an innovative way to customize clothing from the comfort of your own home. This transformative method allows you to create vivid designs that can be printed onto a unique film and then seamlessly transferred onto various fabrics. Whether you’re a DIY enthusiast eager to explore custom apparel printing or a budding entrepreneur looking to profit from your creativity, understanding the DTF transfer process is essential. Our guide will take you through each step of DTF printing, from preparing your design to the final application, ensuring you achieve professional results. By mastering this technique, you’ll harness the power of heat transfer methods to elevate your wardrobe and express your personal style.

The world of custom apparel printing is evolving, and one of the most exciting techniques to emerge is direct to film (DTF) printing. This contemporary approach allows for design versatility, enabling enthusiasts and small businesses alike to produce high-quality, customizable clothing. By utilizing the DTF transfer procedure, you can bring your creative visions to life on an array of textiles, providing a unique touch to your garments. With a little knowledge and resources, you can easily navigate the complexities of the DTF printing tutorial. Embracing this innovative transfer method not only enhances your design capabilities but also positions you at the forefront of modern apparel customization.

Understanding the Benefits of DTF Transfers

DTF transfers, or Direct to Film transfers, offer a multitude of advantages for those looking to delve into custom apparel printing. One of the main benefits is their incredible versatility; this method can accommodate a wide range of fabric types, including cotton, polyester, and their blends. This flexibility allows designers and hobbyists to create unique pieces that suit various applications, from t-shirts to hoodies and beyond. Furthermore, DTF printing provides vibrant and detailed outputs that rival traditional printing techniques. It’s perfect for intricate designs, making it a go-to choice for custom clothing where visual impact is essential.

Another significant benefit of DTF transfers is their cost-effectiveness. Unlike some traditional methods that require extensive setup and materials, DTF printing is particularly well-suited for low to medium batch productions, which is ideal for hobbyists or small businesses starting out. It eliminates the need for large minimum orders, allowing creators to produce personalized pieces at a lower cost and without excess waste. Additionally, DTF transfers have a shorter lead time; designs can be printed and transferred quickly, providing a fast turn-around for projects and orders.

Essential Materials for DTF Printing Success

To begin your DTF transfer journey, gathering the right materials is crucial for achieving high-quality results. The first essential is a DTF printer, which is specifically designed to work with transfer films and adhesive powders. While some may choose to adapt existing printers, investing in a dedicated DTF printer guarantees optimal performance and output. DTF film sheets are another critical component; these specialized films have a unique coating that enables your designs to adhere properly during the heat transfer process.

In addition to the printer and film, adhesive powder plays a vital role in the DTF transfer process. This powder, which must be applied onto the printed film while the ink is still wet, ensures a solid bond between the ink and the fabric upon heat application. A quality heat press machine is also necessary, as it provides the consistent temperature and pressure required for transferring your designs accurately. Lastly, graphic design software is indispensable for creating and refining your artwork, and familiarity with tools like Adobe Illustrator will enhance your ability to produce eye-catching designs.

Step-by-Step Guide to the DTF Transfer Process

The DTF transfer process is straightforward but requires careful attention to detail for optimum results. Begin with the design creation step—using graphic design software, you can customize your artwork to fit the dimensions of your target fabric. Ensure that you set the resolution to 300 DPI for a clear output. Conducting a test print on regular paper can help you visualize how the final image will appear and allow you to make necessary adjustments before moving on to the DTF film.

Once satisfied with your design, print it onto the DTF film. Always double-check that the printer settings are appropriately configured to ensure the best possible print quality. Following this, you need to apply a layer of adhesive powder immediately after printing, before curing it with either a heat press or an oven. This powder activates the adhesive properties, preparing the film for effective transfer. Finally, align the printed DTF film on the fabric, utilize the heat press at the correct temperature, and press firmly to ensure the design adheres, creating a piece ready to showcase.

Tips for Perfecting Your DTF Transfer Technique

To master DTF transfers, embracing resourceful learning techniques is essential. Engaging with DTF printing tutorials available on platforms such as YouTube can provide you with valuable insights from experienced practitioners. These visual aids guide you through each step of the process while featuring tips and tricks that could enhance your efficiency and results. Observing real-time demonstrations helps you understand the nuances of equipment setup, adjustment of settings, and troubleshooting common issues.

Moreover, become an active participant in online communities centered around DTF printing. Forums and social media groups are fantastic resources for connecting with fellow enthusiasts who share their experiences, solution strategies, and cues for overcoming technical challenges. By networking within these communities, you can expand your knowledge and discover new techniques or materials that might elevate your DTF printing skills to new heights.

Common Mistakes to Avoid in DTF Printing

As with any craft, avoiding common pitfalls can significantly enhance your DTF printing experience. One frequent mistake made by beginners involves neglecting the importance of printer settings. Ensure that you select the correct print quality and paper type—using standard paper settings can lead to inadequate ink application and poor image quality. Additionally, not allowing the adhesive powder to cure properly is another oversight; failing to do so can cause designs to lift or peel off the fabric after washing.

Moreover, be mindful of the cooling period after pressing your DTF transfer. Rushing to peel the film before it has cooled can result in incomplete adhesion of the design to the fabric. Additionally, consider cleaning your equipment regularly to avoid clogs in your DTF printer and ensure consistent performance. By staying aware of these common mistakes, you can prevent frustrating trials and ensure a smoother and more enjoyable DTF printing journey.

How to Care for DTF Printed Apparel

Once you’ve successfully created your custom apparel with DTF transfers, knowing how to care for them is key to maintaining their quality and longevity. Begin by washing garments inside out in cold water. This approach helps to preserve the vibrancy of the print while reducing wear and tear. It’s advisable to avoid harsh detergents and bleach as they can damage the integrity of the adhesive and ink used in DTF printing.

Another essential tip is to air dry your DTF-printed items whenever possible. If using a dryer, opt for a low heat setting to protect the transfer from high temperatures that might cause it to crack or peel. Additionally, refrain from ironing directly on the printed design; instead, use a protective cloth to shield it if necessary. By following these care guidelines, your custom creations will remain beautiful, promoting both their aesthetic appeal and durability.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film that can be applied to fabric using heat and pressure. This process allows for high-quality, vibrant prints to be transferred onto various materials, making it a versatile choice for custom apparel printing.

What materials do I need for the DTF transfer process?

To successfully complete the DTF transfer process, you will need a DTF printer, DTF film sheets, adhesive powder, a heat press machine, and graphic design software to create your designs.

Can I use any printer for DTF printing?

While some hobbyists convert existing printers for DTF printing, a specialized DTF printer is recommended to produce high-quality prints on DTF film sheets, ensuring optimal results in the transfer application.

How do I get started with a DTF printing tutorial?

To get started with DTF printing tutorials, seek online resources such as YouTube videos or blogs that cover the DTF transfer process step-by-step, focusing on design creation, printing, and application methods.

What are the advantages of using DTF transfers compared to other heat transfer methods?

DTF transfers offer several advantages, including the ability to print on a variety of fabric types, producing vibrant colors and sharp details, and being cost-effective for low to medium batch productions, making them ideal for custom apparel.

How do I ensure my DTF transfers last through washing?

To ensure your DFT transfers last, make sure to follow the correct heat transfer application settings and press the fabric with a protective sheet afterward. This enhances the design’s durability against washing and wearing.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | A printing method using film transfers, known for vibrant, detailed prints and versatility on fabric. |

| Materials Required | DTF printer, film sheets, adhesive powder, heat press machine, graphic design software. |

| Step-by-Step Process | 1. Design Creation 2. Printing on DTF Film 3. Applying Adhesive Powder 4. Transfer Application 5. Cooling and Peeling 6. Final Touches |

| Benefits of DTF Transfers | Versatile, high-quality results, cost-effective for small to medium batches. |

| Tips for Success | Watch tutorials, join online communities for support and feedback. |

Summary

DTF transfers are revolutionizing the way custom apparel is created, enabling enthusiasts to express their creativity at home. This method combines advanced printing technology with user-friendly processes, making it accessible to all skill levels. By mastering DTF transfers, you can achieve professional-looking results on a variety of fabrics, ensuring that your designs are not only vibrant and detailed but also durable. The step-by-step guide outlined above provides a solid foundation to start experimenting with DTF printing techniques, allowing you to transform your unique designs into wearable art.