DTF transfers, or Direct to Film transfers, are revolutionizing the garment decoration industry by allowing creatives and business owners alike to produce vibrant, high-quality designs with ease. This innovative printing technique excels at transferring intricate artworks directly onto fabrics, making it a favored choice among both professionals and DIY enthusiasts. By mastering DTF transfers, you can unlock a world of stunning design possibilities that not only catch the eye but also withstand the test of time. In this guide, we will explore essential DTF printing tips and effective design techniques for DTF that will enhance your print quality and help navigate common DTF printing issues. From the initial setup to the final curing process, we have everything you need to ensure visually striking and durable results.

The world of garment printing has been transformed with the introduction of direct film transfers, a method that creates stunning fabric designs through a precise application process. Known for their ability to deliver vibrant colors and detailed imagery, these transfers have quickly become indispensable tools for modern designers and small businesses. Understanding the nuances of this innovative printing approach enables creators to effectively produce eye-catching apparel that stands out in any market. In this overview, we’ll delve into practical advice and strategies related to film transfer printing, including preparation techniques and solutions for common issues, ensuring a seamless experience from concept to creation. Embrace the potential of transfer printing and elevate your design game to new heights.

Understanding DTF Transfers: The Future of Garment Decoration

DTF (Direct to Film) transfers are transforming the garment decoration landscape, enabling designers to achieve high-quality prints with intricate details and vibrant colors. Unlike traditional methods, DTF printing allows for direct application of designs onto various types of fabric, making it a versatile choice for apparel decorators. This innovative technique not only enhances creativity but also caters to both small businesses and hobbyists looking for professional-grade results. By leveraging the unique capabilities of DTF, one can create eye-catching artworks in a fraction of the time.

The significance of DTF transfers lies in their ability to bring complex designs to life without the limitations posed by other printing methods. For instance, the DTF printing process allows for better gradients, finer details, and a broader color palette. Additionally, the built-in adhesive properties of DTF transfers ensure that prints remain vibrant and durable even after multiple washes, making it ideal for clothing items that need to withstand daily wear. Understanding these advantages can help you harness the full potential of DTF printing for your projects.

Essential DTF Printing Equipment for Optimal Results

When diving into DTF printing, ensuring you have the right equipment is paramount for achieving optimal results. The foundation of any successful DTF operation begins with a quality DTF printer that is designed to accommodate the unique needs of this printing method. Look for printers that ensure consistent ink flow and are compatible with DTF-specific inks to ensure high resolution and clarity in your designs. Additionally, don’t overlook the significance of high-quality DTF transfer films which can greatly influence the output’s texture and feel.

Moreover, investing in the right pigments is crucial. The choice of ink directly impacts the print quality and longevity of your designs. High-quality pigment inks not only provide rich colors but are also formulated for better adhesion to the transfer films. Alongside printers and inks, consider procuring a reliable heat press to finish your DTF transfer process. A good heat press allows for precise control of temperature and pressure, both of which are essential for achieving durable results in garment decoration.

Perfecting Your Design Preparation Techniques

Preparation plays a significant role in the DTF printing process. The first step in preparing your design should involve utilizing vector graphics software such as Adobe Illustrator. Vector graphics are crucial for maintaining quality at any size; this means your designs remain sharp and vibrant, irrespective of the scaling. Additionally, ensure that your color profiles are accurately set up to align with printing outputs, as this will directly affect the final print quality. Proper color management helps to produce designs that are true to the colors you intended.

Another important tip in the design preparation step is to always mirror your designs before sending them to print. This technique ensures that the final output appears correctly aligned on the fabric. Skipping this step can lead to frustrating mistakes that waste materials and time. Furthermore, being meticulous in matching the design to the type of substrate you are using can enhance the overall print quality, reducing instances of defects. With meticulous preparation, your DTF prints are bound to impress.

Navigating the DTF Printing Process with Precision

The printing process is where all your preparation pays off, but it requires precision to achieve excellent results. Begin by adjusting your DTF printer settings in accordance with the transfer film you are utilizing. Calibration is key; incorrect ink density settings can lead to common printing issues such as ink bleeding or an undermined design quality. Ensure that your printer is maintained and updated to keep up with the demands of DTF printing.

Once your settings are finalized, you can proceed to print your design. Take care to load the DTF transfer films correctly to ensure it feeds smoothly through the printer. Any hiccup in this stage can compromise the consistency of your output, leading to imperfect transfers. A smooth and consistent printing process ensures that your designs maintain high quality across multiple prints—a vital aspect for businesses that wish to scale their offerings.

Mastering Adhesive Application for Durable Transfers

After printing your designs onto DTF film, the next critical step is the application of adhesive. Utilizing a high-quality powdered adhesive specifically meant for DTF transfers is essential to ensure that the ink adheres properly to the fabric. Applying the adhesive should be done promptly while the ink is still wet. Ensuring even coverage is key; too little can compromise the transfer, while too much can lead to an altered hand feel of the fabric, which may not be desirable for customers.

The application process requires finesse as well. Use specialized tools or sprayers to ensure that your adhesive is applied evenly across the printed areas. This meticulous effort prevents common issues related to peeling or bubbling in designs, which can detract from the overall quality. Mastery of this step means you can produce long-lasting, high-quality garments that meet the expectations of your clients or projects.

Troubleshooting Common DTF Printing Issues Effectively

As with any printing process, DTF can present challenges. Understanding common issues such as bubbling transfers or incomplete designs is crucial for any printer. Bubbling often arises from incorrect heat settings or inadequate pressure during the pressing phase. Thus, familiarizing yourself with the ideal temperature and pressure for each type of transfer is vital for achieving a perfect finish. Adjusting these settings based on specific project requirements helps to mitigate potential issues.

Incomplete transfers can be particularly frustrating and often occur due to improper surface prep or insufficient curing time. Ensuring that your fabric is clean and prepped correctly before applying the DTF transfer can significantly impact the outcome. Additionally, respecting the recommended curing period is crucial; rushing this step can lead to poor adhesion, resulting in prints that don’t last. Equipped with troubleshooting skills, you can maintain the quality of your DTF prints, ensuring they stay vibrant and durable.

Frequently Asked Questions

What are some essential DTF printing tips for beginners?

As a beginner in DTF transfers, it’s important to focus on using high-quality DTF printing supplies, including a dedicated DTF printer and transfer films. Start by mastering design techniques for DTF, such as using vector graphics for scalability and adjusting your color profiles for accurate printing. Don’t forget the importance of mirroring designs before printing and applying the adhesive promptly for the best results.

How do I improve DTF print quality for my designs?

To enhance DTF print quality, ensure you’re using top-tier DTF transfer films and pigment inks tailored for DTF printing. Calibrate your printer settings for optimal ink density, and prepare your designs carefully by using appropriate color profiles. Curing your transfers correctly with a heat press is also essential to achieve vibrant colors and ensure durability.

What are common DTF printing issues and how can I resolve them?

Common DTF printing issues include bubbling transfers, incomplete designs, and peeling. Bubbling can often be fixed by adjusting heat press settings for temperature and pressure. Incomplete transfers might stem from inadequate surface preparation or curing time, while peeling may indicate issues with adhesive application or heat settings. Always follow manufacturer guidelines for best results.

What techniques should I use when preparing designs for DTF transfers?

When preparing designs for DTF transfers, utilize vector graphics software like Adobe Illustrator or CorelDRAW to ensure quality. Always adjust your color profiles to match printing capabilities and mirror your designs to ensure they appear correctly on fabric. These design techniques for DTF are crucial for achieving stunning outputs.

How do I properly use DTF transfers in garment decoration?

To use DTF transfers effectively in garment decoration, start by setting up your DTF printer with the appropriate settings for film and ink. Print your mirrored design on transfer film, and promptly apply DTF-specific adhesive. Cure the transfer with a heat press according to manufacturer instructions to ensure lasting adhesion and durability.

What care should I provide after using DTF transfers on fabrics?

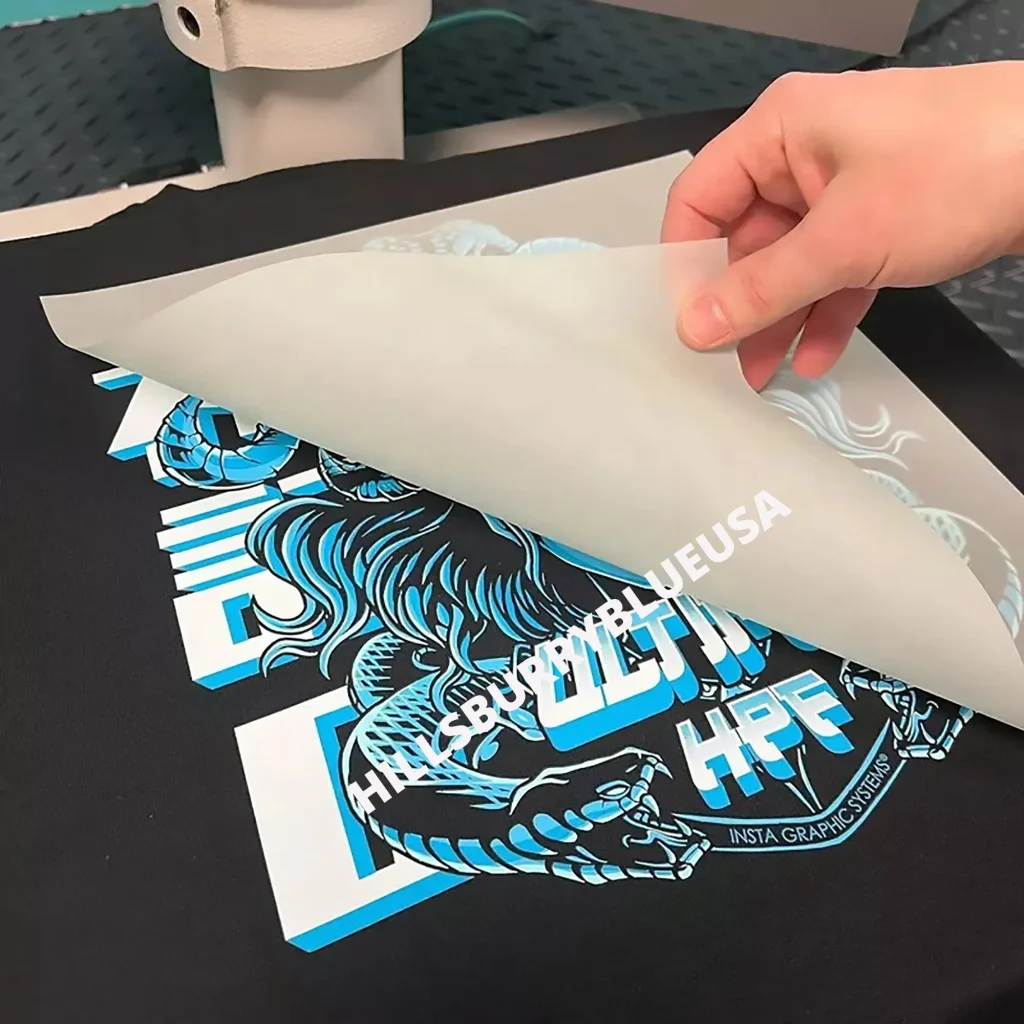

After applying DTF transfers to fabrics, allow the transfer to cool completely before removing the film to prevent any lifting. Provide washing instructions that advise against hot water and recommend air drying to maintain print quality. Proper post-transfer care is essential for ensuring the longevity of the vibrant DTF designs.

| Key Points | Description |

|---|---|

| Understanding DTF Printing | DTF printing transfers artwork from a film to fabric, producing high-resolution and vibrant designs. |

| Essential Equipment | Requires a DTF printer, transfer films, and pigment inks specifically designed for high-quality output. |

| Design Preparation | Prepare designs using vector graphics software, adjust color profiles, and mirror designs for accurate transfers. |

| The DTF Printing Process | Set up printer settings correctly to manage ink density and ensure proper film feeding during printing. |

| Adhesive Application | Apply powdered adhesive immediately after printing for optimal bonding to fabric. |

| Curing the Transfer | Use heat pressing at the recommended settings to cure the transfer properly. |

| Post-Transfer Care | Allow transfers to cool and provide appropriate washing instructions to maintain print longevity. |

| Troubleshooting | Address common issues like bubbling, incomplete transfers, and peeling by adjusting settings and checking adhesive application. |

Summary

DTF Transfers have revolutionized the garment design industry, allowing for vibrant and durable prints that captivate audiences. This printing technique merges technology and creativity, offering designers an unparalleled method to bring their visions to life on a variety of fabrics. By mastering the essentials covered in this guide, anyone can produce professional-quality designs that not only look stunning but also stand the test of time. Understanding the process, from equipment selection to troubleshooting, is integral to achieving remarkable results, ensuring that those who venture into DTF transfers can distinguish themselves in a competitive market.