DTF transfers, or Direct-to-Film transfers, are revolutionizing the garment printing industry with their remarkable ability to deliver high-quality designs on a variety of fabrics. This innovative technology utilizes Digital Transfer Film (DTF) to create vibrant and sharp prints, making it an alluring option for those in textile decoration. The benefits of DTF are undeniable, from its versatility across multiple materials to its cost-effective manufacturing process, which helps businesses maximize profitability. Whether you’re a small-scale operation or an established clothing line, adopting DTF printing can significantly enhance product quality and customer satisfaction. Join the wave of digital transformation in garment printing by exploring the advantages DTF transfers have to offer.

When it comes to modern fabric decoration, Direct-to-Film printing emerges as a powerful solution for businesses seeking to elevate their garment designs. Commonly referred to as DTF technology, this approach harnesses the capabilities of digital transfer films to produce vivid prints that stand the test of time. Among the myriad benefits of using transfer prints lies their adaptability to various textiles and their efficiency in small batch productions. As more enterprises adopt this digital transfer method, the custom apparel landscape continues to evolve, bringing forth quality, durability, and rapid turnaround times that set businesses apart in today’s competitive market.

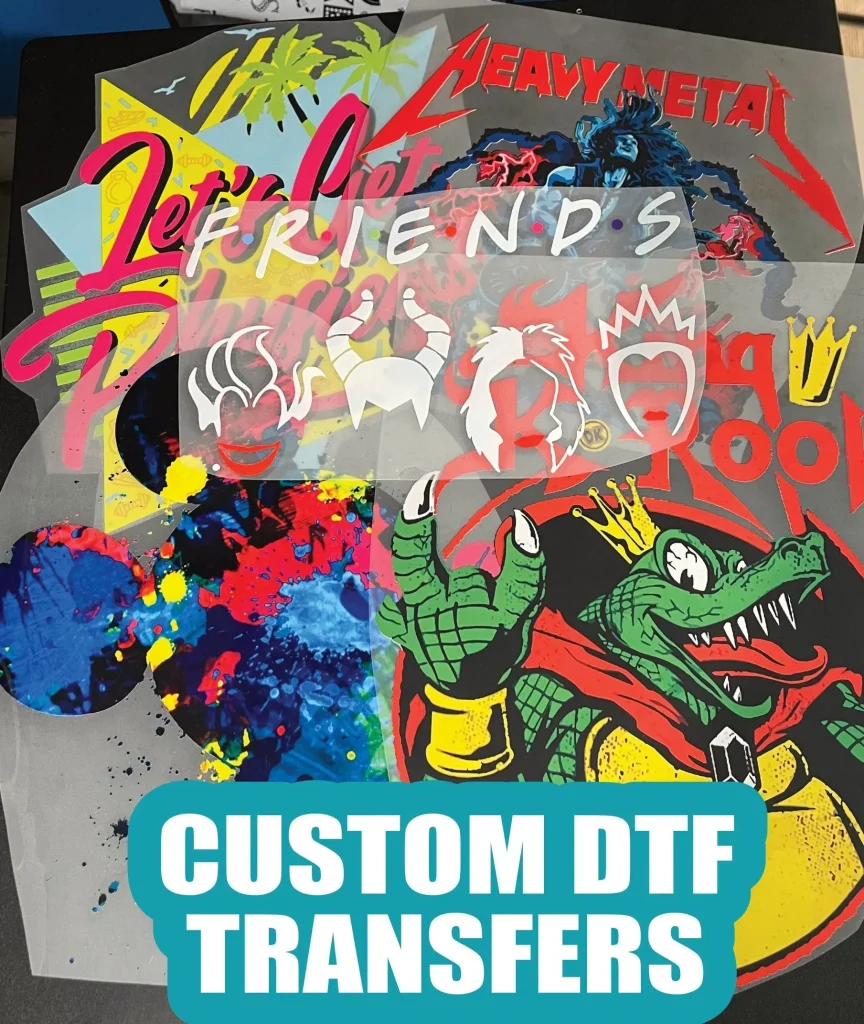

Unpacking the DTF Printing Process

To fully grasp the advantages of DTF transfers, it’s essential to understand the intricate process of DTF printing. The journey begins with creating a digital design, which is crucial for achieving precision and clarity in the final outcome. Once the design is ready, it’s printed onto a special type of Digital Transfer Film (DTF) using a DTF printer. Here, the innovative use of white ink is paramount, as it acts as a foundation for the vibrant colors that follow.

After the design is printed onto the DTF film, an adhesive powder is applied. This step is vital because it ensures that the finished design will adhere properly to various fabrics during the heat-pressing stage. Finally, the coated film is heat pressed onto the garment, activating the adhesive, which binds the ink to the fabric. This straightforward yet effective process showcases why DTF printing is becoming the go-to choice for many custom garment printing businesses.

Advantages of DTF Transfers for Custom Apparel

When it comes to custom apparel, DTF transfers offer an impressive array of benefits that can enhance your product offerings. Versatility is one of the standout features, as DTF printing can be used on various fabric types, including cotton, polyester, and blends. This adaptability means businesses can expand their garment lines without the need for multiple printing setups, thus streamlining operations.

Moreover, the quality of prints produced through DTF technology is simply unparalleled. The ability to print vibrant colors and intricate designs, even on dark fabrics, opens up boundless creative possibilities for apparel designs. This combination of versatility and quality makes DTF transfers a compelling choice for anyone in the custom garment printing industry.

Cost-Effectiveness of DTF Transfers in Production

One of the most attractive aspects of using DTF transfers is the cost-effectiveness they bring to the production process. Traditional printing methods, such as screen printing, often involve expensive setup costs, which can be prohibitive for small to medium-sized orders. In contrast, the DTF printing process allows businesses to minimize upfront investment while still achieving a high-quality finished product.

Additionally, DTF transfers contribute to reduced fabric waste, thanks to their efficient use of materials. This is particularly beneficial in a market that increasingly demands sustainability. By choosing DTF transfers, businesses can improve their profit margins without compromising on the quality and durability of their garment prints.

The Ease of Application with DTF Technology

One of the standout features of DTF transfers is their simplicity of application, making them accessible to both large-scale manufacturers and small business owners or hobbyists. The use of a heat press simplifies the process significantly; operators can easily apply the transfer onto various fabrics without intricate training. This user-friendly approach not only boosts productivity but also ensures that businesses can quickly fulfill customer orders.

This efficiency is especially crucial in today’s fast-paced market, where rapid turnaround times can significantly impact customer satisfaction. With DTF technology, small businesses can achieve high-quality results with minimal investment in terms of time and training, allowing them to focus on scaling their operations and fulfilling customer demands.

Durability of DTF Printed Garments

When it comes to garment printing, durability is a key determinant of customer satisfaction. DTF transfers excel in this aspect, producing prints that resist fading and can endure multiple washes without compromising their vibrant look. This longevity translates to satisfied customers who appreciate high-quality products that maintain their appearance over time.

The robust nature of DTF prints also means that businesses can confidently market their apparel as high-quality offerings, reducing the rate of returns and exchanges due to printing issues. Customers increasingly prioritize durability when selecting apparel, making DTF transfers a smart choice for businesses looking to establish a reputation for quality and reliability.

The Eco-Friendly Promise of DTF Printing

In an age where consumers are becoming more eco-conscious, DTF printing emerges as a more environmentally friendly option in the garment printing industry. Innovations in DTF technology are leading to the use of more sustainable materials and inks, which significantly contribute to reducing the environmental footprint of the printing process. Businesses leveraging this technology can appeal to a growing segment of eco-conscious consumers who prioritize sustainable practices.

Moreover, as industries evolve, those adopting environmentally friendly practices often find themselves ahead of the curve. By integrating DTF printing into your operations, you not only enhance your product offerings but also position your brand as one that values sustainability and responsibility. This alignment with eco-friendly principles can serve as a strong selling point in marketing your custom garments.

Frequently Asked Questions

What are the key benefits of DTF transfers for garment printing?

DTF transfers provide several key benefits for garment printing, including versatility across various fabrics, high-quality and detailed prints, cost-effectiveness for small orders, an easy application process, durability against washing, quick turnaround times, and environmentally friendly options. This combination makes DTF technology a top choice for businesses looking to enhance their printing capabilities.

How does DTF printing compare to traditional garment printing methods?

DTF printing stands out from traditional methods like screen printing by offering lower setup costs, versatility across fabric types, and the ability to produce vibrant prints on dark textiles. Unlike screen printing, which is costly for small runs, DTF allows for high-quality outputs without the need for extensive equipment or inventory, making it more accessible for smaller businesses.

Can DTF transfers be applied to all types of fabrics?

Yes, DTF transfers are versatile and can be applied to a wide range of fabrics including cotton, polyester, and blends. This ability allows businesses to create custom designs on different textiles without needing separate printing processes, making DTF an adaptable solution for various garment printing needs.

How durable are prints made with DTF technology?

Prints created with DTF technology are known for their exceptional durability. They can withstand repeated washing and exposure to sunlight without fading or losing quality. This longevity ensures that garments maintain their vibrant designs over time, leading to satisfied customers and reducing the need for reprints.

What is the application process for DTF transfers?

The application process for DTF transfers is straightforward. It involves printing the design onto a digital transfer film, applying adhesive powder, and using a heat press to bond the design to the garment. This simplicity makes it accessible for small businesses, allowing for quick turnaround times and minimal training.

Why should businesses consider switching to DTF printing technology?

Businesses should consider switching to DTF printing technology due to its numerous advantages, such as high-quality prints, cost-effectiveness for small and large productions, versatile fabric compatibility, and simpler application processes. Additionally, DTF transfers offer eco-friendly options, helping businesses appeal to environmentally conscious consumers while boosting efficiency.

| Benefit | Description |

|---|---|

| Versatility Across Fabrics | Works on various fabrics including cotton, polyester, and blends, allowing for diverse product creation. |

| High-Quality and Detailed Prints | Delivers vibrant and detailed prints, including the use of white ink for dark textiles. |

| Cost-Effective Solutions | Lower setup and material costs, ideal for small order batches, maximizing profitability. |

| Easy Application Process | Simple heat press application, reducing training time and speeding up order fulfillment. |

| Durability That Lasts | Robust prints that withstand washing and fading, ensuring long-lasting quality. |

| Quick Turnaround Times | Faster production speeds cater to customer demands for quick delivery, beneficial for seasonal sales. |

| Eco-Friendly Alternatives | Advancements in DTF technology promote environmentally friendly practices, appealing to eco-conscious consumers. |

Summary

DTF transfers represent a revolutionary approach in the garment printing industry, offering a host of advantages that can significantly enhance your business operations. With their versatility across fabrics, ability to produce high-quality prints, cost-effectiveness, and ease of application, DTF transfers are quickly becoming the preferred method for many businesses. Their durability ensures that products maintain their vibrant designs even after multiple washes, while the quick turnaround times allow companies to meet urgent customer demands efficiently. Moreover, the eco-friendly nature of DTF technology aligns with contemporary consumer preferences, making it not just a practical choice, but a strategic one as well. Switching to DTF transfers could very well be the key to elevating your printing business and staying ahead in a competitive market.