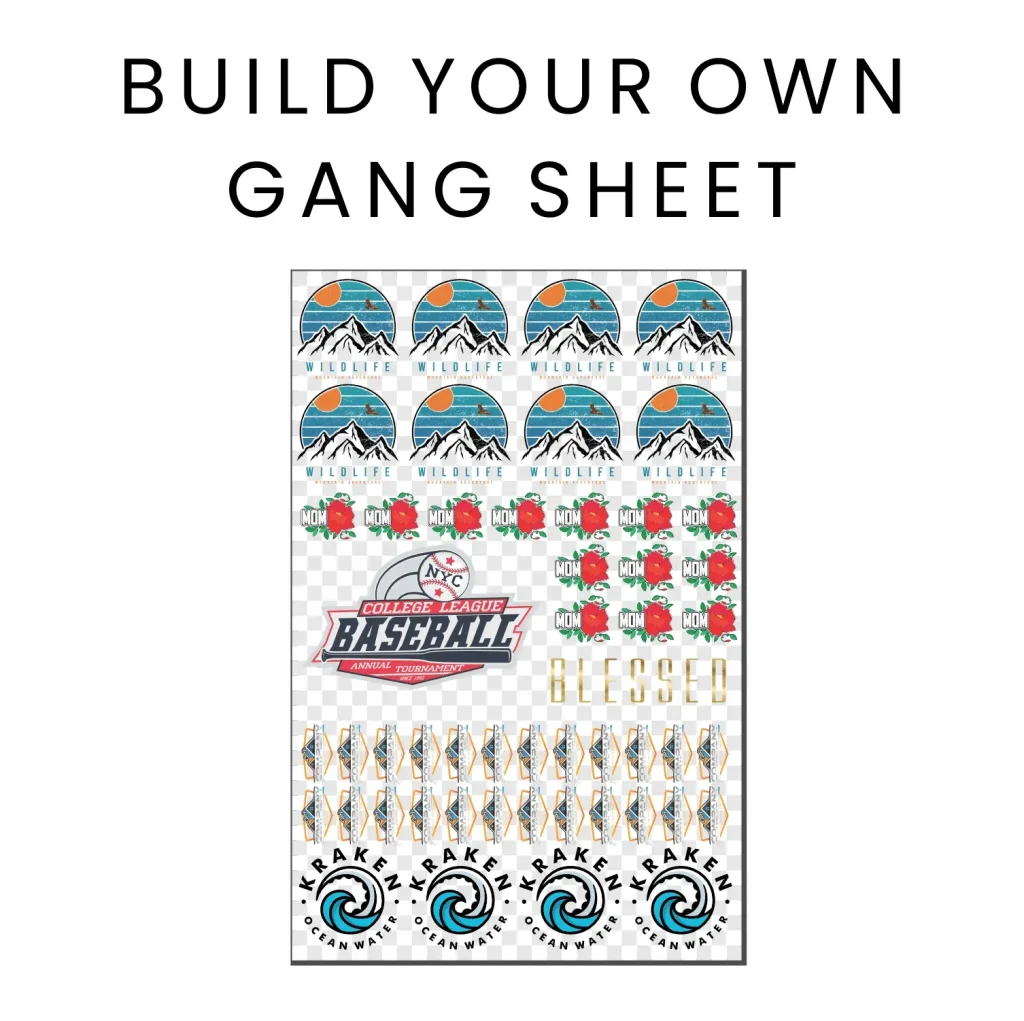

In the rapidly evolving world of fabric printing, the **DTF Gangsheet Builder** has emerged as a revolutionary tool that empowers creators and businesses alike. It streamlines the DTF (Direct to Film) printing process, allowing users to organize several designs onto a single gang sheet for maximum efficiency. This not only enhances productivity but also reduces material waste, making it a smart choice for eco-conscious printers. Whether you are a beginner looking for **DTF printing tips** or an experienced professional seeking advanced **DTF printing techniques**, utilizing a DTF gangsheet builder can significantly elevate your custom apparel printing endeavors. From vibrant designs to intricate details, this innovative tool is essential for anyone aiming to make a mark in the competitive world of fabric printing.

The **DTF Gangsheet Builder**, often referred to as the gang sheet printing tool, is transforming how custom designs are achieved in the fabric printing landscape. This versatile solution allows printers to consolidate multiple artwork designs onto a single sheet, maximizing both efficiency and output. Emphasizing effective **fabric printing** techniques, the builder enables creators to explore various styles and motifs without compromising quality. As brands and individuals alike turn to gang sheets for their printing needs, mastering this tool becomes paramount for successful custom apparel production. With its emphasis on optimizing resources while ensuring stunning results, the gang sheet approach is a game changer in the realm of DTF printing.

Maximizing Efficiency with DTF Gangsheet Builder

Utilizing a DTF Gangsheet Builder is crucial for enhancing productivity in the printing process. By allowing multiple designs to be organized on one sheet, printers can significantly cut down on ink usage and fabric waste. This method not only provides financial benefits but also streamlines the workflow, as you can batch process orders efficiently. As a result, businesses can handle larger volumes of custom apparel printing without compromising quality or speed.

Moreover, implementing gang sheets ensures that you maintain consistency across all prints. By using a standardized sheet, you can adjust your designs with precision and replicate successful outputs easily. This approach is particularly helpful for promotional items where brand consistency is key. Overall, a DTF Gangsheet Builder is an essential tool for anyone looking to optimize their fabric printing endeavors.

Important DTF Printing Tips for Beginners

When delving into DTF printing, it’s vital for beginners to familiarize themselves with some essential tips that will enhance their learning experience. Start by ensuring that every design is well-prepared before printing. This includes checking the resolution and ensuring each image is set to at least 300 DPI to achieve crisp details. Additionally, familiarize yourself with color settings; using RGB color profiles is advisable to ensure that your prints have vibrant, accurate colors when finally applied to fabric.

Another critical aspect is knowing the capabilities of your DTF printer. Different printers may have unique settings and requirements that can affect print quality. Reading the manual thoroughly and experimenting with different designs will improve your skill over time. Keeping notes of what works best and what doesn’t will provide invaluable insights into effective DTF printing techniques.

Design Layout Strategies for Gang Sheets

The art of designing layout for gang sheets can significantly influence the final product’s success. To maximize the available space, it’s essential to group designs efficiently, ensuring that each design is spaced appropriately for cutting. The goal here is to minimize waste while ensuring that each design maintains its integrity post-transfer. Utilizing graphic design software can assist in visualizing the final print layout before committing to printing.

Moreover, it’s advantageous to incorporate a variety of designs into a single gang sheet for diverse orders. This approach not only showcases your versatility but also allows you to cater to different customer needs without requiring multiple printing sessions. Striking the right balance between variety and spacing will ultimately enhance your productivity and creativity in the DTF printing process.

Choosing High-Quality Materials for DTF Printing

Selecting the right materials is paramount in achieving outstanding results in DTF printing. The transfer film and ink quality directly affect the vibrancy and durability of your prints. It’s recommended to invest in high-grade DTF films that are designed specifically for your printer model. Poor-quality films can lead to fading, smudging, and inconsistent transfers, which can tarnish your reputation as a custom apparel printer.

Ink quality is equally important. Always opt for premium DTF inks to ensure consistency and vibrancy across all prints. High-quality inks not only provide better results in terms of color but also contribute to the longevity of your designs on fabric. By choosing the right materials, you lay a solid foundation for remarkable custom prints that your customers will cherish.

Temperature and Pressure Settings for Successful Transfers

Nailing down the ideal temperature and pressure settings for your heat press is vital for successful design transfers in DTF printing. This process may require some trial and error to identify the perfect balance, but generally, settings around 320°F to 350°F with firm pressure yield optimal results. Every substrate is different, so adjustments may be necessary depending on the type of fabric and DTF film used.

Additionally, it’s important to monitor your settings closely during the printing process. Keeping a temperature gauge handy can help you spot any discrepancies in real-time. A well-executed transfer will result in vibrant, long-lasting designs that adhere perfectly to the fabric, ensuring customer satisfaction and offering a competitive edge in the custom apparel market.

Post-Processing: Enhancing Print Quality

Post-processing is a critical phase in DTF printing that is often overlooked but crucial for enhancing overall print quality. Once your design has been transferred, allowing it to rest for several hours is essential. This period permits the inks to set properly, ensuring that they bond effectively with the fabric. Rushing this step can lead to subpar results where colors may crack or fade after washing.

Furthermore, consider applying a protective layer after the initial setting period to enhance the durability of the design. Products specifically designed for fabric printing can provide an additional shield against wear and tear, extending the life of your prints. By prioritizing post-processing, you ensure that your custom prints remain vibrant and appealing even after several washes.

Frequently Asked Questions

What is the DTF Gangsheet Builder used for in DTF printing?

The DTF Gangsheet Builder is a tool that maximizes efficiency in DTF printing by allowing multiple designs to be arranged on a single sheet. This not only reduces material waste but also streamlines the printing process for custom apparel and fabric printing projects.

How can I optimize gang sheets when using my DTF Gangsheet Builder?

To optimize gang sheets with your DTF Gangsheet Builder, group designs closely together while ensuring adequate spacing for trimming. This layout strategy maximizes the use of space, saves costs, and enhances production efficiency.

What are the best DTF printing techniques to ensure high-quality prints?

For high-quality DTF prints, use a DTF Gangsheet Builder to layout your designs, prepare files in high resolution (at least 300 DPI), and maintain RGB color settings. These techniques ensure vibrant colors and sharp details in your final prints.

Why is file resolution important when using a DTF Gangsheet Builder?

File resolution is crucial when using a DTF Gangsheet Builder because high-resolution files (minimum 300 DPI) prevent pixelation and ensure clear, professional-looking prints. Low-resolution images can compromise the quality of your fabric printing results.

What materials should I use with my DTF Gangsheet Builder for optimal results?

For optimal results with your DTF Gangsheet Builder, use high-quality transfer films and specialized DTF inks tailored to your printer model. Quality materials prevent issues like fading and smudging, ensuring long-lasting, vibrant prints on fabrics.

What are the temperature and pressure settings for a heat press when using DTF Gangsheet Builder?

When using a DTF Gangsheet Builder, the recommended heat press settings are typically between 320°F to 350°F with firm pressure. It’s important to experiment within this range to find the best settings for your specific fabric and film type.

| Key Points | Details |

|---|---|

| Introduction to DTF Printing | DTF printing is a versatile method for creating vibrant designs on fabrics, using a transfer film for direct application. |

| Benefits of DTF Printing | High-quality prints on various fabrics, suitable for custom apparel and promotional items. |

| Layout Optimization | Efficiently group designs on gang sheets to minimize waste and save material. |

| Maintaining Design Variability | Vary the artwork on gang sheets while maintaining adequate spacing for trimming. |

| Preparing Files for Printing | Files should be high resolution (300 DPI) for clarity and vibrant colors prefer RGB settings. |

| Quality Materials | Use high-quality DTF transfer films and specialized inks for best results. |

| Optimizing Printing Process | Experiment with heat and pressure settings (320°F to 350°F recommended) for optimal transfers. |

| Post-Processing Steps | Let prints rest for a few hours post-printing to enhance quality and durability. |

Summary

DTF Gangsheet Builder is an essential tool for anyone looking to create high-quality textile prints effortlessly. By understanding the nuances of DTF printing and implementing the effective techniques outlined in this guide, users can maximize their productivity while reducing costs. Utilizing optimized gang sheets not only preserves fabric but also emphasizes the vibrancy of each design, resulting in stunning final products. As you continue to innovate with your DTF Gangsheet Builder, you’ll find that crafting eye-catching prints becomes an exciting and rewarding process.