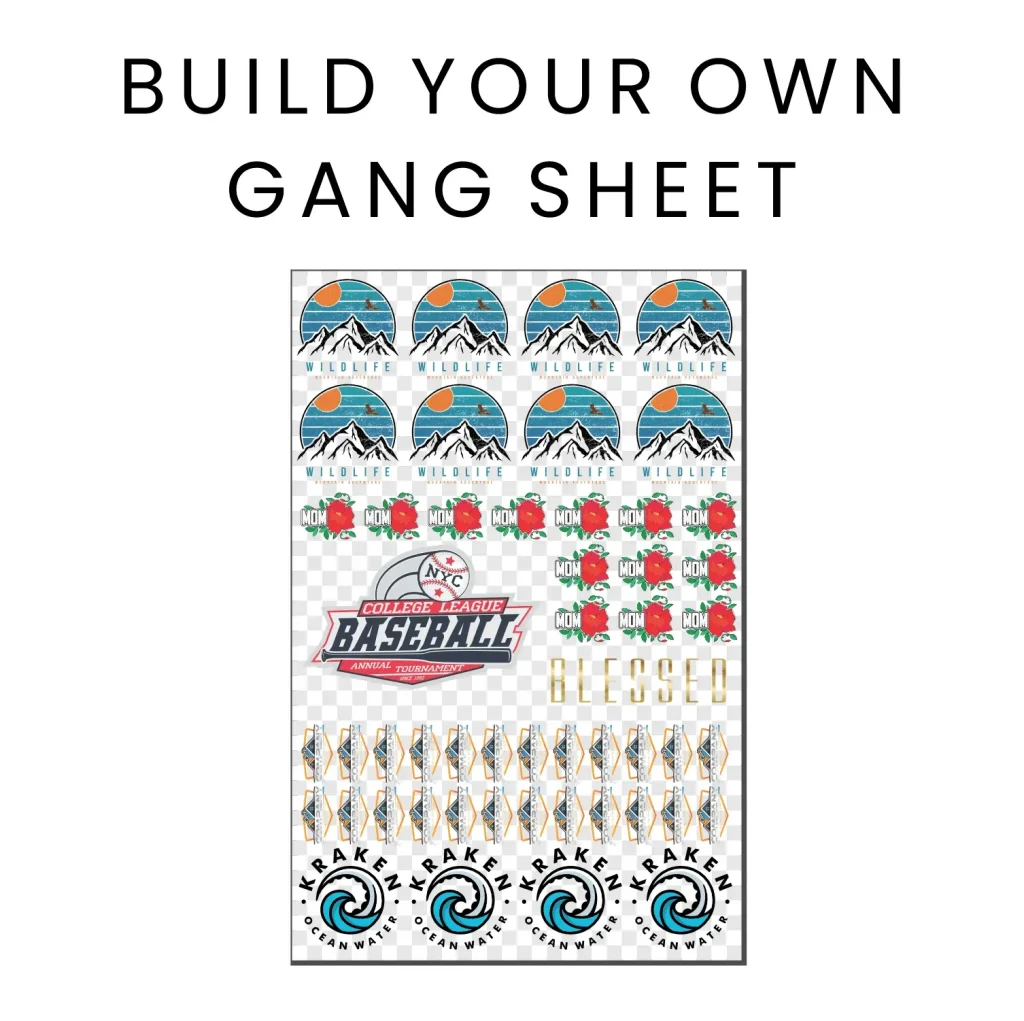

The **DTF Gangsheet Builder** is a game-changing tool that streamlines the process of direct-to-film printing, allowing users to combine multiple designs on a single sheet. This innovative software enhances efficiency by maximizing print space and minimizing waste, making it an essential asset for professionals in the custom apparel industry. If you’re curious about DTF printing tips or wondering how to use DTF gang sheets effectively, you’ll find that leveraging this builder can significantly cut down on print costs while improving overall productivity. Best practices for DTF printing emphasize the importance of design arrangement and software compatibility, two vital features offered by the DTF Gangsheet Builder. As we explore its functionality, you’ll discover how to optimize this tool to achieve stunning results in your printing projects.

Direct-to-Film (DTF) printing has transformed custom print production, with the gang sheet method at its core. By facilitating the simultaneous printing of multiple designs, it allows for faster turnarounds and reduced material waste. When discussing the intricacies of gangsheet printing, one cannot overlook the essential role that DTF software plays in orchestrating an efficient workflow. Understanding how to best organize designs, select compatible materials, and implement effective testing methods can elevate your printing business. This guide will delve into the benefits of utilizing a DTF Gangsheet Builder, ensuring you harness the full potential of this remarkable technique.

Overview of DTF Printing Techniques

DTF printing, or Direct-to-Film printing, has become a game changer in the custom apparel industry, providing a vibrant alternative to traditional methods. With the ability to print intricate designs directly onto a film and then transfer them onto fabrics, DTF offers exceptional quality and versatility. This technique is not only efficient but also allows for the printing of complex colors and gradients, making it ideal for multi-colored designs.

Understanding the essence of DTF printing is crucial for any business aiming to capitalize on custom apparel sales. By utilizing a DTF Gangsheet Builder, users can maximize their printing capabilities, streamline the production process, and significantly reduce costs. This approach rolls multiple designs onto a single sheet, allowing for faster processing times and reducing material wastage.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a tool used for combining multiple designs into a single print job in DTF (Direct-to-Film) printing. This method maximizes print space, reduces waste, and lowers costs by allowing simultaneous application of several designs onto garments.

What are the best practices for using the DTF Gangsheet Builder effectively?

Best practices for using the DTF Gangsheet Builder include optimizing design arrangement by spacing out images to avoid overlap, ensuring software compatibility for easy resizing, selecting high-quality transfer films, and conducting test prints before larger production runs.

How can I improve my DTF printing results with gang sheet techniques?

Improve DTF printing results by strategically arranging your designs to maximize space on the gang sheet, using compatible DTF software for optimal quality, and choosing the right materials that ensure excellent adhesion and durability for various fabrics.

What software is best suited for creating DTF gang sheets?

For creating DTF gang sheets, look for user-friendly software that allows easy resizing and arranging of designs without quality loss. Software specifically tailored for DTF printing often includes features that enhance productivity and optimize print layouts.

Is it necessary to perform test prints with the DTF Gangsheet Builder?

Yes, conducting test prints with the DTF Gangsheet Builder is crucial. Test runs help you identify potential color discrepancies and alignment issues before moving to larger production runs, ensuring the final prints meet quality expectations.

What are the benefits of gangsheet printing in DTF applications?

Gangsheet printing in DTF applications offers several benefits, including reduced waste, cost efficiency by maximizing the use of print materials, and streamlined production processes that enable faster turnaround times for custom apparel.

| Topic | Details |

|---|---|

| Introduction to DTF Printing | DTF printing allows high-quality designs on various materials, focusing on gang sheets for efficiency. |

| Understanding Gang Sheets | Gang sheets enable strategic design placements for optimal production and reduced waste. |

| Key Advantages of Gang Sheets | 1. Reduced Waste 2. Cost Efficiency 3. Streamlined Production |

| Tips for Effective Use | 1. Design Arrangement 2. Software Compatibility 3. Material Considerations 4. Testing Before Larger Runs |

| New Developments in DTF Technology | Compact printers enhance accessibility for small businesses, making DTF printing more viable. |

Summary

The DTF Gangsheet Builder is your go-to solution for optimizing custom printing workflows. By understanding how to effectively use this tool, you can significantly enhance your production efficiency while keeping costs low. Key practices such as careful design arrangement, choosing the right software, selecting quality materials, and performing tests can greatly improve your final results. As new technologies emerge, mastering the DTF Gangsheet Builder will not only streamline your processes but also elevate your custom apparel offerings, ensuring you stay competitive in the market.